72 duster resto

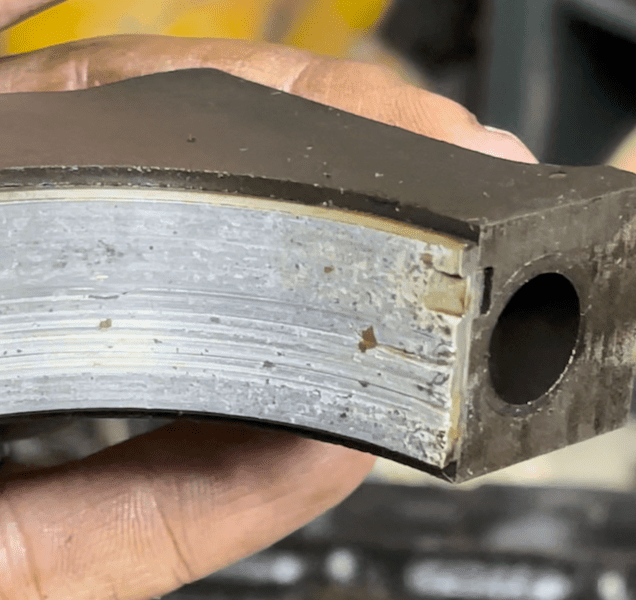

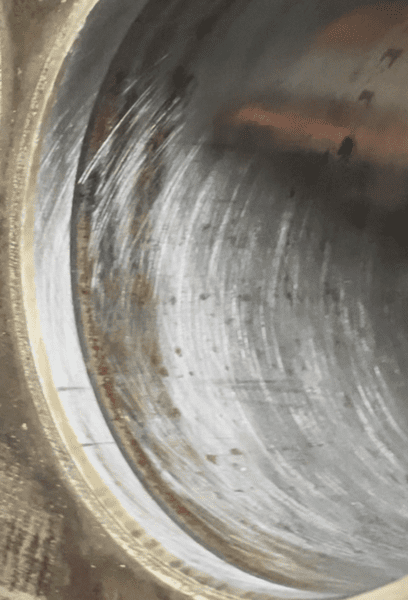

Alright crank pulled out, bearings definitely shot on the mains. One had deep grooves and inflicted gouges on opposite side on the crank journal :( Photos attached but I realize it's hard to judge with those. But trust me, deep grooves there and that could cause pain later like slipping a bearing, etc.

Knowing the machine shop down the street charges $400 for a bore / $400 for a hone - I might not even bother with asking for a quote for R&R on this crank. Any suggestions on a new one if I ditch this thing?

Also, pulled out the cam

202136 printed on one end

Measured

1.56-1.24”

Rocker ratio = 1.5

.48 duration so probably the purple

484 single pattern camshaft Purple Mopar cam P4120231 -->Lift .484/.484

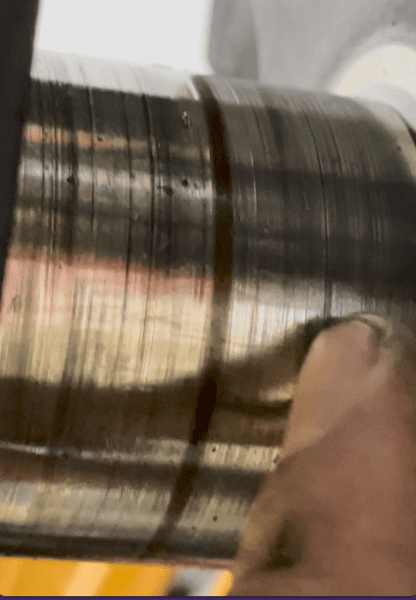

Also started honing the cylinders

Lookin' much better for sure. Small spot on one cylinder that looks like it has some pitting that I might see if I can hone out.

Overall, my plan is:

Figure out my crank options

Hone all the cylinders

Decode my cam

Deep clean the block, oil passages, water jackets(acid wash)

heat, acetone, prime and paint the block

Rebuild kit with new bearings everywhere, new gaskets, etc

Slowly learn how to build back the block for install

I know it's not a perfect route but given that the alternative requires over $1k more for a machine shop bore & hone + oversized pistons i'd just rather put a new crank in, put it all back best I can and send it

Alright crank pulled out, bearings definitely shot on the mains. One had deep grooves and inflicted gouges on opposite side on the crank journal :( Photos attached but I realize it's hard to judge with those. But trust me, deep grooves there and that could cause pain later like slipping a bearing, etc.

Knowing the machine shop down the street charges $400 for a bore / $400 for a hone - I might not even bother with asking for a quote for R&R on this crank. Any suggestions on a new one if I ditch this thing?

Also, pulled out the cam

202136 printed on one end

Measured

1.56-1.24”

Rocker ratio = 1.5

.48 duration so probably the purple

484 single pattern camshaft Purple Mopar cam P4120231 -->Lift .484/.484

Also started honing the cylinders

Lookin' much better for sure. Small spot on one cylinder that looks like it has some pitting that I might see if I can hone out.

Overall, my plan is:

Figure out my crank options

Hone all the cylinders

Decode my cam

Deep clean the block, oil passages, water jackets(acid wash)

heat, acetone, prime and paint the block

Rebuild kit with new bearings everywhere, new gaskets, etc

Slowly learn how to build back the block for install

I know it's not a perfect route but given that the alternative requires over $1k more for a machine shop bore & hone + oversized pistons i'd just rather put a new crank in, put it all back best I can and send it