Been thinking through these details the last few days and I think it would work but wanted to pose the idea here to get thoughts. I know I could add a mechanical gauge but I'd rather have one tucked within the instrument cluster that isn't carrying oil. So this discussion will be if the concept is feasible/would work

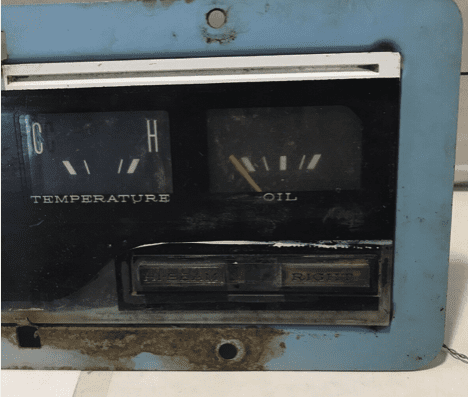

The gauge from a late 60 early 70 dodge truck. I'd have an overlay printed to add some numbers to the face to copy the look of the temp gauge.

Doesn't appear to be using any kind of PCB for this cluster and I'm not seeing any voltage regulator. Assuming the oil gauge would be 12v driven or (regulated within the gauge)

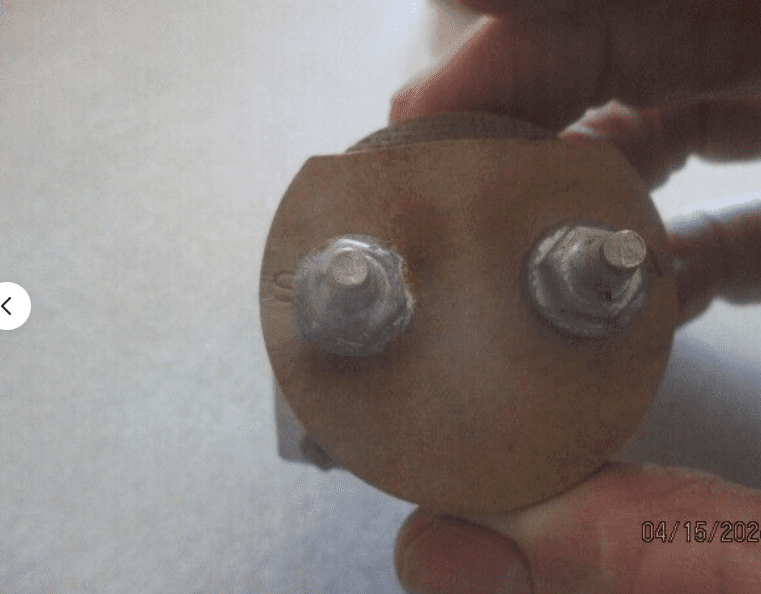

Here is the Oil Sending Unit to drive that gauge. Just swap old for new

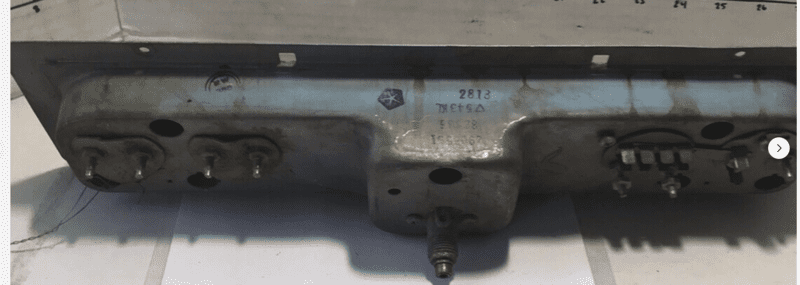

71+ board

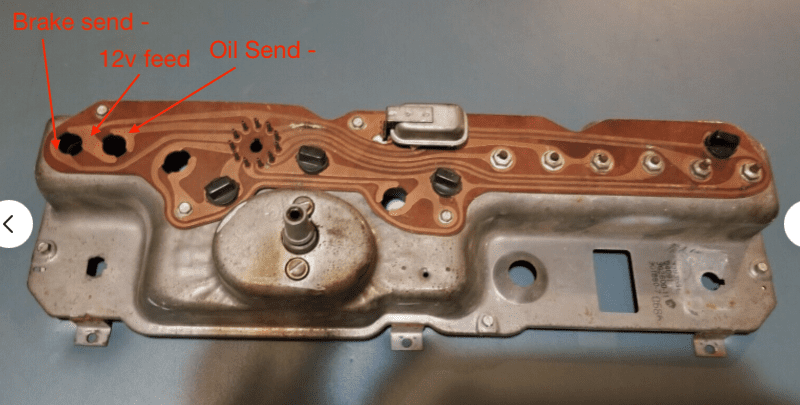

I would use a nylon hat washer that's sized to the diameter of those bulb holder holes and run the gauge posts through them and hold them in with some speed nuts like the ones on the fuel/temp/ammeter gauge posts.

Jumper from oil send trace to appropriate post on gauge. Jumper ground to the other post.

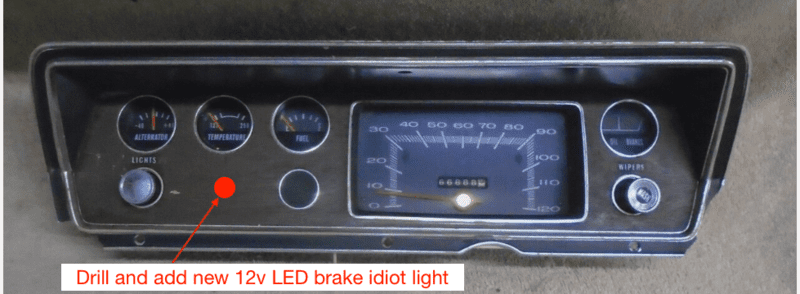

I will have to look at the cluster bezel but I think the OIL BRAKES text below the idiot lights is on a piece that can be removed from the cluster and modified with an overlay that simply says OIL

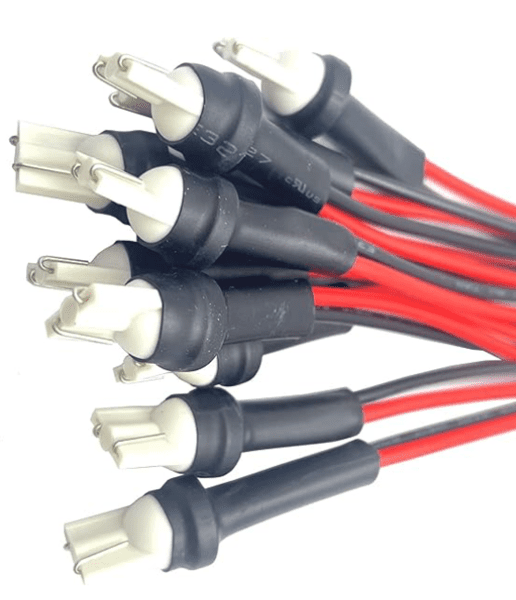

install one of these for the new brake idiot light wired to ground and original trace feed.

Then fix the dim night lighting (and light up the new oil gauge) with some tape LEDs from the side, across the top and down the other side.

Tapped for power using one of these in one of the backlighting bulb sockets

The gauge from a late 60 early 70 dodge truck. I'd have an overlay printed to add some numbers to the face to copy the look of the temp gauge.

Doesn't appear to be using any kind of PCB for this cluster and I'm not seeing any voltage regulator. Assuming the oil gauge would be 12v driven or (regulated within the gauge)

Here is the Oil Sending Unit to drive that gauge. Just swap old for new

71+ board

I would use a nylon hat washer that's sized to the diameter of those bulb holder holes and run the gauge posts through them and hold them in with some speed nuts like the ones on the fuel/temp/ammeter gauge posts.

Jumper from oil send trace to appropriate post on gauge. Jumper ground to the other post.

I will have to look at the cluster bezel but I think the OIL BRAKES text below the idiot lights is on a piece that can be removed from the cluster and modified with an overlay that simply says OIL

install one of these for the new brake idiot light wired to ground and original trace feed.

Then fix the dim night lighting (and light up the new oil gauge) with some tape LEDs from the side, across the top and down the other side.

Tapped for power using one of these in one of the backlighting bulb sockets

Last edited: