Ah, just realised I

can't see some of the photos when i look at this at work. just looked on phone and now can. i'll come back and edit below as its wide of the mark for that carb

(later) added a bit at the bottom after this bit that is potentially not that useful...

there is always confusion due to the move from brass to spancil (plastic/foam) floats and differing gasket thicknesses. with ethanol petrol, a modern ethanol proof plastic float is probably best

also be aware of changes to thread pitch and taper on idle mix screws as well. between old and new spanish. 1.5 turns on an old carb can be 3 turns on a new one

i don't know much about DGV apart from running something vaguely related on my Mums citroen year ago, but the usual process is to take off the lid

hold it vertically with the float pivot at the top and with the float hanging down, so that it just touches the tip of the needle valve.

check the distance between the top of the float and the gasket against the, lid at the mid point up the float top surface.

18 or 20 mm doesn't sound too out-there...

the gasket stays in place, because it is in place when assembled, adjusting the height of the lid, by its thickness, when installed.

Easiest way is to use a metric or the closest equivalent imperial drill bit shank this will be the closet thing to a gauge block you own unless you are an engineer.

the spacing differs between the two types of float due to their differing density.

you bend the tab so that it just touches the tip of the needle valve when the float is pressed against the drill bit shank

the droop is less important

the aim here is to have enough droop to allow the needle valve to flow, at fully open,

to allow the needle to stay open, if the fuel is slopping 1 way or the other, artificially lifting the float. However not so much droop that the tab moves so far away, as to allow the internals of the needle valve to fall out so far as to escape, or to jam and hang-up, causing massive flooding.

As with all weber carbs they were built for specific models of cars back in the 50s/60s/70s the settings were model specific, and float height was varied between models of car/engine depending on the engine and the position of the carb on that engine

to take into account fuel surge foaming etc

In the middle of a V6/8 quite stable. fuel surge mainly fore and aft

hung off the side of a 6 less stable but much smoother operation so less vibration at frequencies that might cause foaming . some fuel surge side to side and fore and aft, dependent on manifold length and how crap the engine mounts are

hung of the side of a 4 cylinder less stable and way more vibration. As above with added fuel foaming

this is kinda true for all carbs

so float height on a 6 or v8 may be higher than on a 4.

if you can find a plastic float setting from float top to cover. you are on the right track.

find a model list and see if your carb was used on another six cylinder like an MGC or triumph six, etc the setting for float height would be appropriate, as it is linked not only to when the main circuits come in but also to the engine type and mounting position of the carb.

try to make sure the carb faces the same way it did on an engine that weber made a version of the carb for.

later on, a small change to raise or lower it could be used to deal with a flat spot in transition or a period of over richness in the same rpm range. although i doubt these carbs have the same sensitivity to this kind of thing that the DCOE and IDF do.

if stuck, email webcon in the UK they are mainly responsible for the fact you can still buy webers new, believe they got magneti marrelli to continue manufacture. they are usually willing to help with what would be standard settings.

they may of course try to sell you something.... but i have not found that to be the case the tech guys will at least give their view on what might be right. given the caveat above i.e standard settings are for the engines that the carb was designed for.

still the best baseline to start from in most cases

i think on a lowish revving slant 6 with a standard two-tower slant 6 fuel pump you would be ok without a regulator. i found my holley one to be more trouble than it was worth.

If you a running an electric pump YES you need one.

most cars that ran weber's as OEM equipment didn't have one, the pressure was tuned by the valving and main spring in the pump. flow is key, a slightly larger needle valve tends to be used on engines with capacities towards the top end of what the carb was designed for.

if the pressure is too high, your wear a groove into the needle valve, you will spot it, and to be honest a replacement is not too much. i.e get a regulator If and when you need one

Dave

did a bit of digging, yes indeed the pictures above are useful now i can see

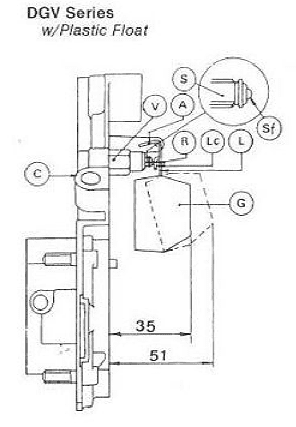

Weber recommends setting the height of a plastic float at 35mm from the bottom of the float to the bottom of the carb top plate, with the plate held vertically and the float hanging downwards, making light contact with the needle valve. (Racing engine builders often recommend adjusting this height to 33mm for a richer mixture in FF1600 racing.)

So can you achieve setting via Bewys set up? using the top of the air horn?

potentially an easier way to set up...

loads of ways to skin this cat...!

if you can achieve neither i presume you have either

1) The wrong float

2) The wrong needle valve

3) the wrong washers under the needle valve

4) The tab on your float has been bent to a position that is messing with the set up and needs to be bent back. Has it been splayed out when the lid was pulled previously i.e float catches in bowel?

you will probably find that 18 mm between top of float and gasket-ed lid is the same as 35mm from bottom of float to the gasketed lid.... unless they changed the design of the float.

but it would be usual to have the float tops more or less parallel to the lid when you are in the right ballpark.

is the carb new or second hand and what was it used on before?

your needle valve looks different not wrong i guess, just different stirrup on it, looks plastic. presume that's a 200

Needle valve DGV / DGAV / DGMS / DGEV / DGAS / DGES / DG | Webcon UK Ltd

picture below stolen and blown up, off webcon site

the floats here are at rest and presume they have pressed the needle valve in as far as it goes under their own weight. hard to tell if your tab is bent differently from this one

but with 2mm travel in the valve i would imagine the floats being kinda parallel to the lid with the tab just touching the tip of the valve.

this lid is probably a 36-36 DGAS but all the same DG type carb.

Dave

View attachment 1716226769

View attachment 1716226775