Here's a quick thread for the newbies on hose clamps and how to properly install them.

There are two basic types of clamps, constant diameter (screw type) and constant tension (spring type).

Constant diameter clamps are the screw type that you adjust to the proper diameter with a screw driver/nut driver. Below is a picture of the constant diameter/screw clamps:

The second type is the constant tension or spring clamps. These are made for a certain size of hose and apply pressure to the hose for sealing. These type are better for sealing.

The "name brand" spring style clamp in the industry is the Mubea hose clamps as pictured below. I have not been able to find an aftermarket source for these, but you may find some at your local dealer, as they are used by OEM car manufacturers. There are also other companies making spring style clamps, but Mubea is very popular with OEM. Here's what the mubea clamps look like:

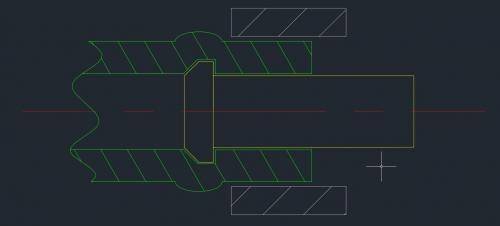

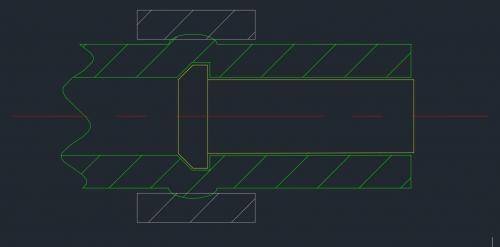

Positioning the clamp is also very important. You have to make sure that the hose goes all the way past the barb on the nipple, and make sure that it goes past the clamp. Here is a diagram showing the hose not on the nipple far enough to reach past the clamp. This is no good as it will not be able to handle as much pressure and could blow off:

Here's a picture of real parts showing not enough hose sticking past the clamp:

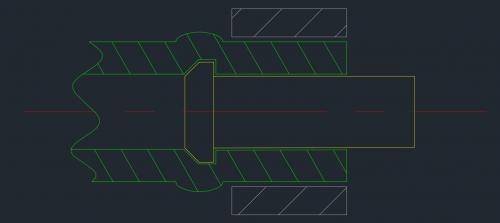

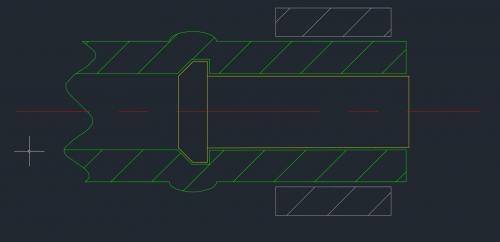

Here's a diagram showing the hose and clamp line to line on the edge, this is no good also as it will not hold as much pressure as if it were properly installed:

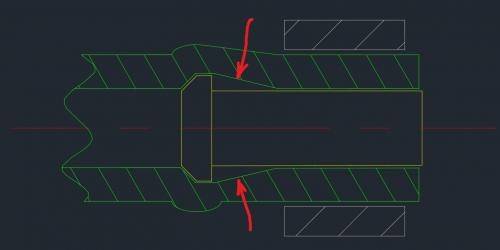

Here are a couple of shots of real parts showing this condition that you don't want:

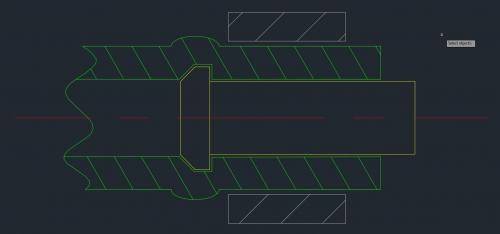

Here's the way that you want to position the hose and clamps. The hose should stick slightly past the clamp by at least 1/8". This allows the hose end to flare out and this will make it much harder for the hose to slip under the clamp and blow off the nipple:

Here I am showing how the hose will flare after the clamp:

Here's what it looks like with real parts:

Here's where I over tightened a clamp on a loose hose to show how the end flares after the clamp:

The position of the clamp is also important. You want to put it just behind the barb, not on the barb, or too far away. By having the clamp just behind the ridge of the barb, it makes it harder for the hose to expand and slip off over the barb as it concentrates pressure on the back of the barb.

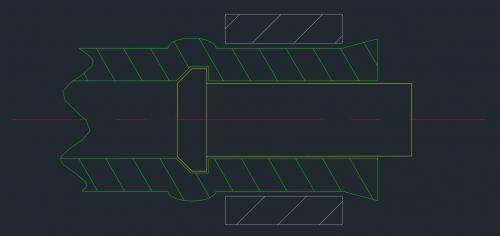

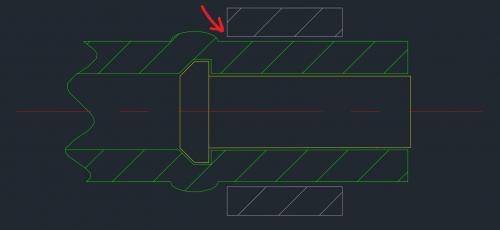

Here's a view to exaggerate not far enough down the hose (overlapping the barb) - NO GOOD:

Here's a view to exaggerate too far away from the barb:

Here's a better way to visualize the clamp too far away from the barb shoulder:

Here's showing what you want, this helps prevent the hose from expanding and slipping over the barb:

Here are a few links for the Mubea spring style clamps that Chrysler used for years on their vehicles. They are the spring style constant tension clamps that keep pressure on the hose so it doesn't leak. You have to get the proper size clamp for the diameter that you are using.

The ones that Chrysler used for years are the Mubea hose clamps. They were bought directly from Mubea by Chrysler.... You have to get the proper size for the hose that you are using...

Mubea - Products & Technologies - Industry - Products - Spring Band Clamps

Mubea - Products & Technologies - Aftermarket - Products - Spring Band Clamps

This gives the specifications for open and closed diameter...

Mubea - Products & Technologies - Automotive - Engine - Spring Band Clamps - Characteristics and Construction - Significant Parameters - Hose Clamp

Edit: Added the Mubea links.

There are two basic types of clamps, constant diameter (screw type) and constant tension (spring type).

Constant diameter clamps are the screw type that you adjust to the proper diameter with a screw driver/nut driver. Below is a picture of the constant diameter/screw clamps:

The second type is the constant tension or spring clamps. These are made for a certain size of hose and apply pressure to the hose for sealing. These type are better for sealing.

The "name brand" spring style clamp in the industry is the Mubea hose clamps as pictured below. I have not been able to find an aftermarket source for these, but you may find some at your local dealer, as they are used by OEM car manufacturers. There are also other companies making spring style clamps, but Mubea is very popular with OEM. Here's what the mubea clamps look like:

Positioning the clamp is also very important. You have to make sure that the hose goes all the way past the barb on the nipple, and make sure that it goes past the clamp. Here is a diagram showing the hose not on the nipple far enough to reach past the clamp. This is no good as it will not be able to handle as much pressure and could blow off:

Here's a picture of real parts showing not enough hose sticking past the clamp:

Here's a diagram showing the hose and clamp line to line on the edge, this is no good also as it will not hold as much pressure as if it were properly installed:

Here are a couple of shots of real parts showing this condition that you don't want:

Here's the way that you want to position the hose and clamps. The hose should stick slightly past the clamp by at least 1/8". This allows the hose end to flare out and this will make it much harder for the hose to slip under the clamp and blow off the nipple:

Here I am showing how the hose will flare after the clamp:

Here's what it looks like with real parts:

Here's where I over tightened a clamp on a loose hose to show how the end flares after the clamp:

The position of the clamp is also important. You want to put it just behind the barb, not on the barb, or too far away. By having the clamp just behind the ridge of the barb, it makes it harder for the hose to expand and slip off over the barb as it concentrates pressure on the back of the barb.

Here's a view to exaggerate not far enough down the hose (overlapping the barb) - NO GOOD:

Here's a view to exaggerate too far away from the barb:

Here's a better way to visualize the clamp too far away from the barb shoulder:

Here's showing what you want, this helps prevent the hose from expanding and slipping over the barb:

Here are a few links for the Mubea spring style clamps that Chrysler used for years on their vehicles. They are the spring style constant tension clamps that keep pressure on the hose so it doesn't leak. You have to get the proper size clamp for the diameter that you are using.

The ones that Chrysler used for years are the Mubea hose clamps. They were bought directly from Mubea by Chrysler.... You have to get the proper size for the hose that you are using...

Mubea - Products & Technologies - Industry - Products - Spring Band Clamps

Mubea - Products & Technologies - Aftermarket - Products - Spring Band Clamps

This gives the specifications for open and closed diameter...

Mubea - Products & Technologies - Automotive - Engine - Spring Band Clamps - Characteristics and Construction - Significant Parameters - Hose Clamp

Edit: Added the Mubea links.