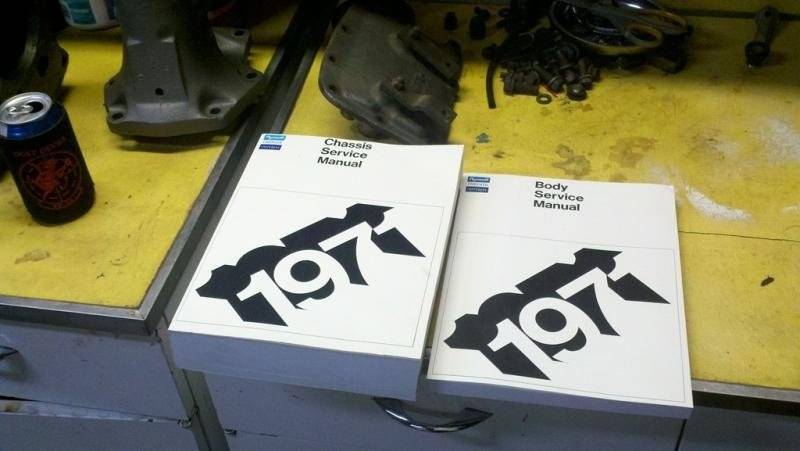

I started rebuilding my tranny so I thought that I would post some pics of the process for those thinking about trying this on their own one day...The first couple pictures are of the manuals I would get as they go into perfect detail and step by step instructions for teardown and buildup. Next are pics of the tranny torn down, and the reverse gear tool I made to get the reverse gear out.

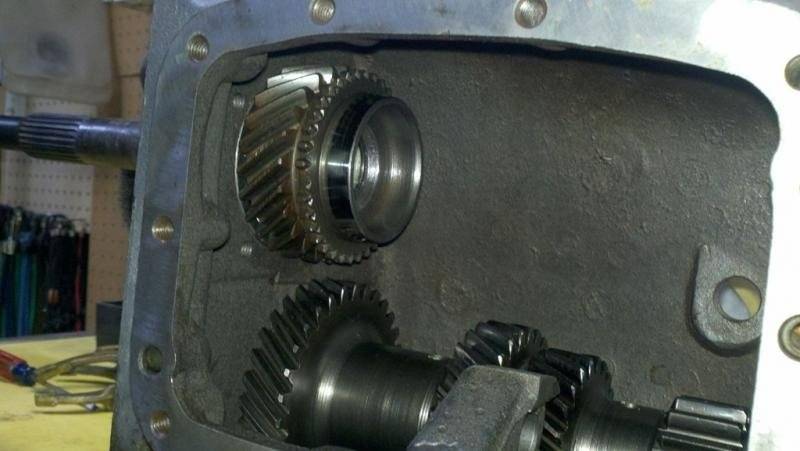

Here are some pictures of the assembly process as I am completing it. I did not post pics of the disassembly since that is the easy part. Just invest in a nice set of snap ring pliers! I also bought a new rebuild kit so I did not have to worry about endplay and bearing wear. I have a piece of mind with new components. Here is an explanation in order of pics from top to bottom:

1) Gears laid out and cleaned up

2) I installed a countershaft arbor and then 2 sets of 19 needle bearings coated with heavy grease (I used transgel from Brewers) on each side of the countershaft.

3) View of arbor dummy shaft installed

4) Opposite side of countershaft with 19 needle bearings installed.

5/6) Final spacers installed.

7) Thrust washers installed.

Final pic: Lay the countershaft in the case and let sit on the bottom. Make sure the thrust washers stay lined up with the case when installing. You will install this after the main input pinion is installed.

Here are some pictures of the main input shaft pinion install and countershaft final install.

1 - I took the main input to the transmission shop to have the bearing pressed on since I do not have a press.

2 - All cleaned up

3 - installed 16 needle bearings plus c-clip

4 - installed input shaft in case

5 - Installed c-clip onto bearing

6/7 - Lift up countershaft until it meshes with input shaft (ensure thrust washers are in position) and drive in shaft with woodruff key installed through the countershaft.

8 - Here is the arbor dummy shaft coming out other end

9 - Final install of countershaft/input shaft

Thanks...glad I can help out! I know I would have loved this tech. Here are some pics of the reverse gear going in. I am going to take the mainshaft to the transmission shop today to get the tailshaft bearing pressed in and then will post pics of the mainshaft buildup.

1 - Reverse assembly laid out and cleaned up.

2/3 - Install a new o-ring on the lever shaft, lube it up and slide it into the case. Install the fork into the lever as well. In this pic I also installed the reverse detent ball, spring gaskets and plug.

4 - Position the reverse idler shaft in end of case.

5 - Install reverse gear with the fork slot facing the rear of the tranny, engage the fork into the gear and then drive the idle shaft through with the woodruff key installed.

6 - Install the backup light switch and gasket

I finally got over to the shop to get the bearing pressed in so here are the mainshaft buildup pics to that point. I plan to finish building the mainshaft tonight and install it into the tailshaft housing so more pics later!

1 - Mainshaft laid out

2 - Slide on 2nd gear (cone towards rear)

3 - Here is the 1st/2nd gear synchronizer. Assemble starting with brass stopring flat on bench followed by clutch gear sleeve. install the struts and then install the strut spring with the tang on the ring in one of the struts. Snap the ends of the strut spring in the remaining two struts. Flip over the sleeve on top of the brass stopring and install another strut spring.

4 - Install one brass stopring, the assembled synchronizer, followed by another stopring. Ensure both stoprings are indexed correctly.

5 - Install 1st speed (cone towards brass stopring)

6 - Install tailshaft main bearing lockring and have bearing pressed on mainshaft.

I plugged away some more on the tranny tonight. Here are some pictures of the tailshaft install.

1 - Install the mainshaft into the tailhousing until bearing is past the groove in the tail housing. This is the hardest part of the whole build...compress the snap ring and push the mainshaft so the snap ring clips into the tailhousing. This process took me a half hour!

2 - Install the 3rd speed gear on the mainshaft (cone facing forward)

3 - Install brass stopring

4 - Here is the step by step process to build up the synchronizers. Lay brass stopring as shown.

5 - Install clutch on stopring

6 - Install sleeve over clutch

7 - Install three struts and install the strut spring with tang on one strut as shown.

8 - Finish installing strut spring in remaining struts. Flip and install spring in opposite side.

9 - Install 3rd/4th synchronizer onto mainshaft (Fork slot facing rear)

10 - Install snapring securing all pieces to mainshaft.

Here are some more pictures of the tranny build:

1 - Install the final stopring with lots of lube!

2 - Final stopring installed

3 - Install the mainshaft/tailshaft assembly into the case. You need to ensure you install the gasket, slide the reverse gear all the way towards the rear and move the 3rd/4th gear synchro forward enough to where the struts do not come out. This will help when installing the assembly.

4 - Once everything bottoms out, torque the tailshaft to the housing.

5 - Painted tranny!

6 - Lay out housing cover

7 - Install new O-rings on the shifter levers

8 - Here is the layout of the shifter interlock

9 - Installed shifter

10 - Final assembly of shifter interlocks

Here are the final pictures of the transmission all completed! All in all this was a very easy process. Hope this helps all you manual bubbas!

1 - Install the shift forks into the synchro grooves in the housing.

2 - Pics of the bellhousing installed

3 - Install the seal in the forward bearing retainer, gasket and install into the front of tranny. Pay attention to the oil groove position!

4 - Install side cover and torque cover bolts and you are finished!

Here are some pictures of the assembly process as I am completing it. I did not post pics of the disassembly since that is the easy part. Just invest in a nice set of snap ring pliers! I also bought a new rebuild kit so I did not have to worry about endplay and bearing wear. I have a piece of mind with new components. Here is an explanation in order of pics from top to bottom:

1) Gears laid out and cleaned up

2) I installed a countershaft arbor and then 2 sets of 19 needle bearings coated with heavy grease (I used transgel from Brewers) on each side of the countershaft.

3) View of arbor dummy shaft installed

4) Opposite side of countershaft with 19 needle bearings installed.

5/6) Final spacers installed.

7) Thrust washers installed.

Final pic: Lay the countershaft in the case and let sit on the bottom. Make sure the thrust washers stay lined up with the case when installing. You will install this after the main input pinion is installed.

Here are some pictures of the main input shaft pinion install and countershaft final install.

1 - I took the main input to the transmission shop to have the bearing pressed on since I do not have a press.

2 - All cleaned up

3 - installed 16 needle bearings plus c-clip

4 - installed input shaft in case

5 - Installed c-clip onto bearing

6/7 - Lift up countershaft until it meshes with input shaft (ensure thrust washers are in position) and drive in shaft with woodruff key installed through the countershaft.

8 - Here is the arbor dummy shaft coming out other end

9 - Final install of countershaft/input shaft

Thanks...glad I can help out! I know I would have loved this tech. Here are some pics of the reverse gear going in. I am going to take the mainshaft to the transmission shop today to get the tailshaft bearing pressed in and then will post pics of the mainshaft buildup.

1 - Reverse assembly laid out and cleaned up.

2/3 - Install a new o-ring on the lever shaft, lube it up and slide it into the case. Install the fork into the lever as well. In this pic I also installed the reverse detent ball, spring gaskets and plug.

4 - Position the reverse idler shaft in end of case.

5 - Install reverse gear with the fork slot facing the rear of the tranny, engage the fork into the gear and then drive the idle shaft through with the woodruff key installed.

6 - Install the backup light switch and gasket

I finally got over to the shop to get the bearing pressed in so here are the mainshaft buildup pics to that point. I plan to finish building the mainshaft tonight and install it into the tailshaft housing so more pics later!

1 - Mainshaft laid out

2 - Slide on 2nd gear (cone towards rear)

3 - Here is the 1st/2nd gear synchronizer. Assemble starting with brass stopring flat on bench followed by clutch gear sleeve. install the struts and then install the strut spring with the tang on the ring in one of the struts. Snap the ends of the strut spring in the remaining two struts. Flip over the sleeve on top of the brass stopring and install another strut spring.

4 - Install one brass stopring, the assembled synchronizer, followed by another stopring. Ensure both stoprings are indexed correctly.

5 - Install 1st speed (cone towards brass stopring)

6 - Install tailshaft main bearing lockring and have bearing pressed on mainshaft.

I plugged away some more on the tranny tonight. Here are some pictures of the tailshaft install.

1 - Install the mainshaft into the tailhousing until bearing is past the groove in the tail housing. This is the hardest part of the whole build...compress the snap ring and push the mainshaft so the snap ring clips into the tailhousing. This process took me a half hour!

2 - Install the 3rd speed gear on the mainshaft (cone facing forward)

3 - Install brass stopring

4 - Here is the step by step process to build up the synchronizers. Lay brass stopring as shown.

5 - Install clutch on stopring

6 - Install sleeve over clutch

7 - Install three struts and install the strut spring with tang on one strut as shown.

8 - Finish installing strut spring in remaining struts. Flip and install spring in opposite side.

9 - Install 3rd/4th synchronizer onto mainshaft (Fork slot facing rear)

10 - Install snapring securing all pieces to mainshaft.

Here are some more pictures of the tranny build:

1 - Install the final stopring with lots of lube!

2 - Final stopring installed

3 - Install the mainshaft/tailshaft assembly into the case. You need to ensure you install the gasket, slide the reverse gear all the way towards the rear and move the 3rd/4th gear synchro forward enough to where the struts do not come out. This will help when installing the assembly.

4 - Once everything bottoms out, torque the tailshaft to the housing.

5 - Painted tranny!

6 - Lay out housing cover

7 - Install new O-rings on the shifter levers

8 - Here is the layout of the shifter interlock

9 - Installed shifter

10 - Final assembly of shifter interlocks

Here are the final pictures of the transmission all completed! All in all this was a very easy process. Hope this helps all you manual bubbas!

1 - Install the shift forks into the synchro grooves in the housing.

2 - Pics of the bellhousing installed

3 - Install the seal in the forward bearing retainer, gasket and install into the front of tranny. Pay attention to the oil groove position!

4 - Install side cover and torque cover bolts and you are finished!