This comes up enough that it seemed worthwhile to create its own thread.

Part 1. Chrysler Vacuum Advance Canisters (pods)

Lets start with how two of the three vacuum advance characteristics can be adjusted. This can be done either to bring the timing to factory specifications, or for custom tuning. Tuning will be covered in parts 2 and 3.

Three aspects of control by the vacuum canister.

a. Amount of advance possible. This can be limited with a piece of wire or sheet metal, or increased by filing.

b. Vacuum required to get it to advance. This can be adjusted by changing the preload (allen key adjuster)

c. Rate of vacuum advance. This is built in (mostly spring rate) and not easily changed.

a. Amount of advance. Limiting total degrees possible

The maximum degrees is determined by the tabs on the vacuum pod's arm.

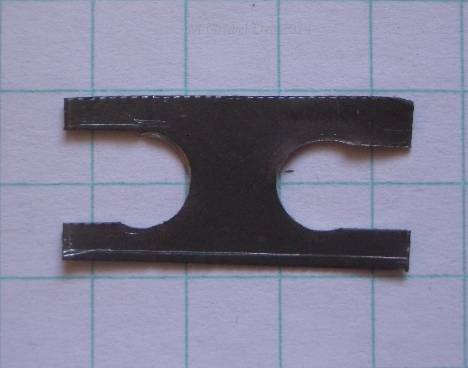

Below is a photo showing the tabs with a wire wrapped around them to limit the advance.

In this particular case, 0.031" piano wire was used. This is difficult to bend nice and neatly. Smaller diameters will be easier. Alternatively, a piece of sheet metal can be drilled and cut into the shape of a finger bandage and wrapped around the tabs.

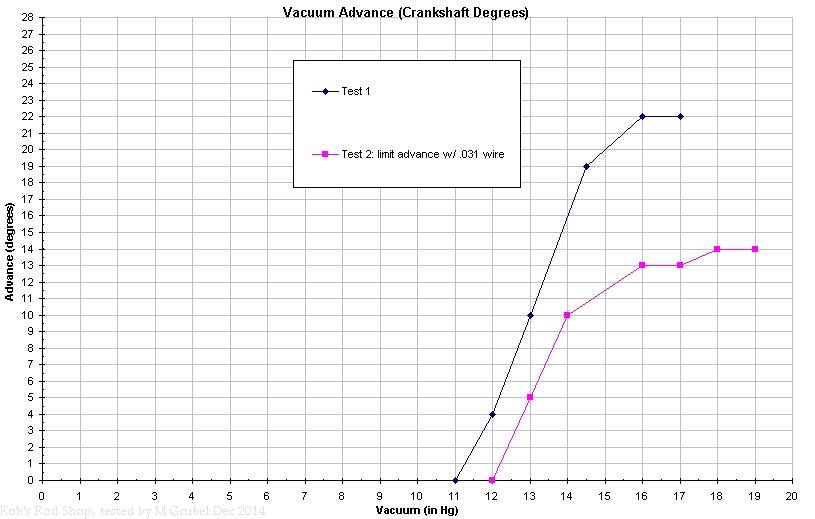

Result of using the 0.031" wire wrap is shown below. (This was a vacuum advance pod for a parts store distributor so its true original application is unknown.) If you are wondering why the start vacuum changed... IIRC its because I goofed and adjusted the spring preload before retesting.

Its probably safe to conclude that .031" wire or sheet metal will reduce the advance approximately 8*. Therefore .015" will reduce it 4* and so forth. Conversely, filing the tabs will increase the total advance possible. (There's not much room to work a file in there.)

However, there is another method of limiting the vacuum advance.

mderoy340 wrote: "To limit the max advance you can mod your distributor by adding a 4-40 machine screw to limit max advance where you want it. See picture."

This stops movement of the advance plate rather than directly acting on the arm.

It should be mentioned that many, but not all, vacuum cans will have the degrees of advance stamped on the arm. This is distributor degrees. Multiply that number by two for crank degrees.

In the photo below is an 8.5 so it can add a maximum of 17 degrees advance.

b. Adjusting Start & Stop Vacuum

Many, but not all, vacuum canisters allow adjustment of the spring's preload. Changing this preload will shift the amount of vacuum needed to start and complete the vacuum diaphram's movement. On older Chrysler and Prestolite built units this is generally done by unscrewing the nipple and changing the washer stack. Cutaway illustration here:

1951 Imperial and Chrysler Service Repair Book - Distributor Repair

For most late 60s and newer Chrysler built distributors, if the canister has a hex shaped end, the preload can be adjusted by turning an internal screw. This is done by inserting a 3/32" hex key (Allen wrench) into the nipple. Counterclockwise = higher vacuum needed to advance.

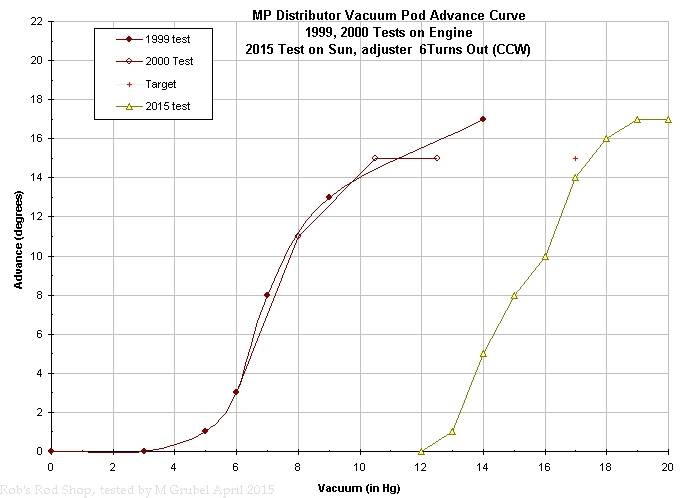

The more preload on the spring, the more vacuum will be required to add advance. Notice the rate of advance is uneffected. If it takes 5 "Hg to move from 0 degrees to 16*, it will still take approximately 5" even if the preload has been increased.

See a cutaway view of the vacuum advance internals here.

Part 2. Vacuum Advance Tuning.

Basics:

The engine timing produced by vacuum advance is in addition to the initial timing and mechanical advance. Therefore it is essential to first establish the mechanical timing curve. This is true whether working with a factory stock engine and timing, or modified, or custom timing.

Goal:

In general, lean mixtures require more time to burn, and therefore more advance. The purpose of the vacuum advance is to provide enough lead time for the slower burning combustion to develop peak cylinder pressure through the most efficient crank angles.

Vacuum advance makes use of manifold vacuum as an indicator of engine load and throttle position. (MAP sensors do essentially the same thing, except they measure the manifold absolute pressure.) Vacuum advance should be added when engine loads are light to moderate as this is when the engine runs most efficiently with lean mixtures.

The questions then are:

How to determine the vacuum when the engine is lean?

How much additional advance is needed.

General Guidelines:

The most practical answer to these questions is to use the factory research and development.

On a stock setup, the answer is relatively easy. The factory engineers did the hard work to produce reliable results under all conditions. Look up the factory specifications in the service manual. Then adjust your unit as required to bring it within spec.

Close to stock. If the mechanical advance has been altered from factory, then you might want to alter the vacuum advance to keep the timing for cruising on the highway the same as the factory had established as best. With a '70s mopar, you may wish to experiment slightly as they may have somewhat adjusted the vacuum advance to reduce certain emissions while driving. Also EGR equipped vehicles can be expected to have slightly different burn rates due to the addition of hot O2.

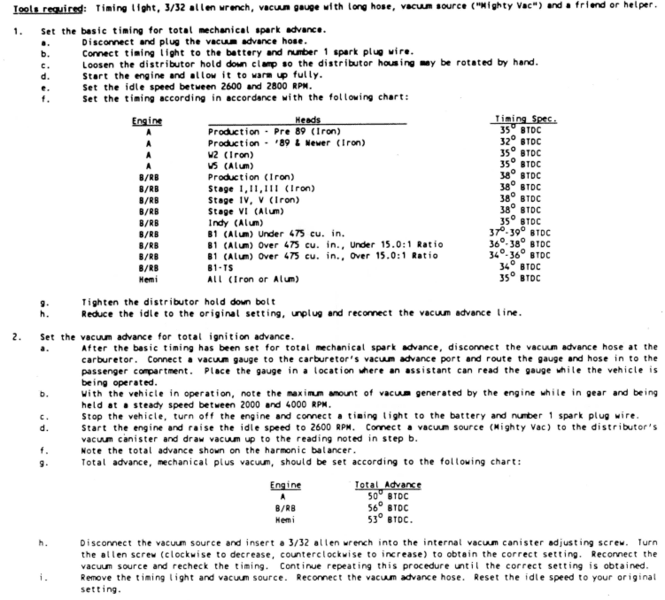

For a modified or custom setup, one can follow Direct Connection's guidelines. In my opinion it is best to use the guidelines from the era of the Chrysler built distributors. Summarized here from Mopar Performance Instructions DCF-194:

A. Establish mechanical timing curve per guidelines. These are based on timing at 2600 - 2800 rpm. A few listed below.

> pre-'89 A/LA iron, 35*, for newer heads, 32*

> B/RB iron 38* Indy Aluminum 35*

B. Measure the manifold vacuum while cruising (highway).

C. Adjust the vacuum advance to get the timing at 2600 rpm and the vacuum measured above:

A engines 50*

B/RB engines 56*

Whether this is done on the engine or on a distributor machine, a vacuum pump will be needed. For example, if the car cruises with manifold vacuum of 17", then bring the engine to 2600 rpm and adjust the vacuum can so the timing reads at 50* (for a small block).

However the MP procedure focuses only on the timing while cruising. If one is willing to adjust both the vacuum advance's limit and when it comes into play, additional tuning is possible. Obviously this requires some experimentation. This additional step seeks to determine when the vacuum advance should begin.

Tune the vacuum advance to equal zero before fuel enrichment is needed. For a Holley, the manifold vacuum of enrichment is known by the power valve stamping. For example, a 1967 440 cid with Holley came with 6.5 power valve. Therefore, the fuel mixture for these engines got richer as the manifold vacuum dropped below 6.5"Hg. We would expect there to be no vacuum advance as the mixture richens up and not surprisingly the service manual shows these engines had no vacuum advance under 8.5 to 9.2" of vacuum.

Too much vacuum advance;

At part throttle and moderate load (acceleration or uphill) will be heard as pinging or gurgling.

At light cruising will feel like "trailer hitching" or "fish biting".

The spark plugs are a good indicator of detonation as well as combustion. Examining the plugs is a good practice.

As timing works hand in glove with both the fuel curve and combustion efficiency, its very helpful to look at the fuel curves. The next post will touch on that.

Part 3. Air-Fuel Ratios and Vacuum Advance

The purpose of adding vacuum advance is to match the slower burning leaner mixes. Ideally, vacuum advance should go away when the engine needs enrichment. Enrichment may be anywhere from 60% to 90% max power depending on the engine and drivetrain.

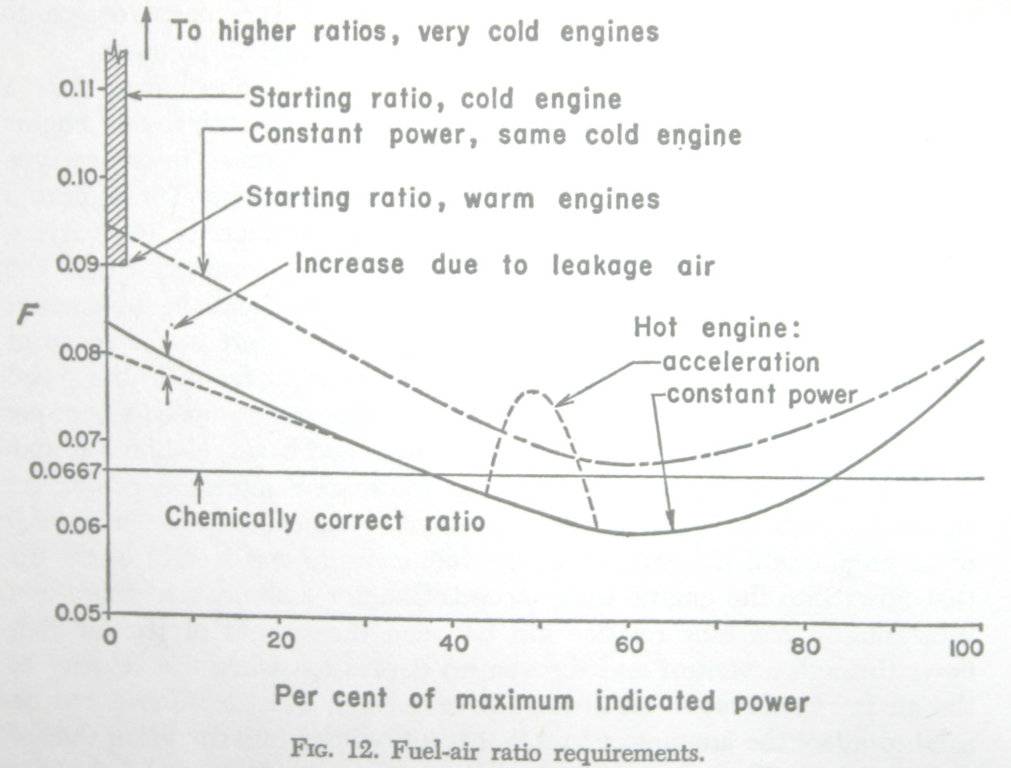

Below is a curve showing the most efficient fuel air ratio for a given load.

F = Fuel/Air ratio. AFR = 1/F

In this example from Larew (details here), enrichment is need around 60 to 70% load, which might equate to vacuum of 9 to 12 "Hg. So, lets say this is the case, and we find a PV or step up around 10.5 works best. So we would want the vacuum advance to go away as vacuum drops near 10.5"

As a real life examples, we can look to various factory engines. In the previous post I used the non-hi performance 1967 440 cid engines with a power valve opening around 6.5" Hg.

However the well known original Holley 3310 carburetors came with 10.5 power valves (primary side) and 8.5" (secondary side). Presumably GM determined that engine had a fuel curve similar to Larew's and needed to go richer earlier due to camshaft, heads, or other factors.

One can test for the best part throttle enrichment points but it is relatively time consuming. One method is by "crowding" vacuum readings with greater and greater throttle openings. Using the best time (or acceleration) to determine the vacuum reading that requires enrichment. Urich and Fisher describe this method for road race tuning in Holley Carburetor and Manifolds. A really good dyno operator, with a load cell dyno, and familiarity with this type of testing should be able to produce similar results. A very very few independent operators have 4-gas and 5-gas analyzers along with the dyno.* This may be the best method but is out of reach for most of us.

*edit: Dug out some of the references to using a gas bench and the main measurement needed for this is nitrous oxides. From one of the "very very few" mentioned above:

"The purpose of the power valve selection is to enrichen the mixture prior to the combustion temperatures going too high. To set a powervalve correctly requires a NOx sensor. Different engine combinations need fuel enrichment at different power levels." and "All that matters is the combustion temperature doesn't get too high and you measure that by measuring Oxides of nitrogen ie NOx. Anytime the powervalve is activated prior to being necessary its wasting fuel."

Bruce "Shrinker" Robertson. post #4 "Another Power Valve Question" archived Innovate Motorsports forum

Slight OT, but perhaps of interest to some is an in depth discussion of NOx formation and performance tuning. Using NOx for performance tuning. - Speed Talk

Timing guidelines from page 2 of Mopar Performance Instruction sheet DCF-194

Part 1. Chrysler Vacuum Advance Canisters (pods)

Lets start with how two of the three vacuum advance characteristics can be adjusted. This can be done either to bring the timing to factory specifications, or for custom tuning. Tuning will be covered in parts 2 and 3.

Three aspects of control by the vacuum canister.

a. Amount of advance possible. This can be limited with a piece of wire or sheet metal, or increased by filing.

b. Vacuum required to get it to advance. This can be adjusted by changing the preload (allen key adjuster)

c. Rate of vacuum advance. This is built in (mostly spring rate) and not easily changed.

a. Amount of advance. Limiting total degrees possible

The maximum degrees is determined by the tabs on the vacuum pod's arm.

Below is a photo showing the tabs with a wire wrapped around them to limit the advance.

In this particular case, 0.031" piano wire was used. This is difficult to bend nice and neatly. Smaller diameters will be easier. Alternatively, a piece of sheet metal can be drilled and cut into the shape of a finger bandage and wrapped around the tabs.

Result of using the 0.031" wire wrap is shown below. (This was a vacuum advance pod for a parts store distributor so its true original application is unknown.) If you are wondering why the start vacuum changed... IIRC its because I goofed and adjusted the spring preload before retesting.

Its probably safe to conclude that .031" wire or sheet metal will reduce the advance approximately 8*. Therefore .015" will reduce it 4* and so forth. Conversely, filing the tabs will increase the total advance possible. (There's not much room to work a file in there.)

However, there is another method of limiting the vacuum advance.

mderoy340 wrote: "To limit the max advance you can mod your distributor by adding a 4-40 machine screw to limit max advance where you want it. See picture."

This stops movement of the advance plate rather than directly acting on the arm.

It should be mentioned that many, but not all, vacuum cans will have the degrees of advance stamped on the arm. This is distributor degrees. Multiply that number by two for crank degrees.

In the photo below is an 8.5 so it can add a maximum of 17 degrees advance.

b. Adjusting Start & Stop Vacuum

Many, but not all, vacuum canisters allow adjustment of the spring's preload. Changing this preload will shift the amount of vacuum needed to start and complete the vacuum diaphram's movement. On older Chrysler and Prestolite built units this is generally done by unscrewing the nipple and changing the washer stack. Cutaway illustration here:

1951 Imperial and Chrysler Service Repair Book - Distributor Repair

For most late 60s and newer Chrysler built distributors, if the canister has a hex shaped end, the preload can be adjusted by turning an internal screw. This is done by inserting a 3/32" hex key (Allen wrench) into the nipple. Counterclockwise = higher vacuum needed to advance.

The more preload on the spring, the more vacuum will be required to add advance. Notice the rate of advance is uneffected. If it takes 5 "Hg to move from 0 degrees to 16*, it will still take approximately 5" even if the preload has been increased.

See a cutaway view of the vacuum advance internals here.

Part 2. Vacuum Advance Tuning.

Basics:

The engine timing produced by vacuum advance is in addition to the initial timing and mechanical advance. Therefore it is essential to first establish the mechanical timing curve. This is true whether working with a factory stock engine and timing, or modified, or custom timing.

Goal:

In general, lean mixtures require more time to burn, and therefore more advance. The purpose of the vacuum advance is to provide enough lead time for the slower burning combustion to develop peak cylinder pressure through the most efficient crank angles.

Vacuum advance makes use of manifold vacuum as an indicator of engine load and throttle position. (MAP sensors do essentially the same thing, except they measure the manifold absolute pressure.) Vacuum advance should be added when engine loads are light to moderate as this is when the engine runs most efficiently with lean mixtures.

The questions then are:

How to determine the vacuum when the engine is lean?

How much additional advance is needed.

General Guidelines:

The most practical answer to these questions is to use the factory research and development.

On a stock setup, the answer is relatively easy. The factory engineers did the hard work to produce reliable results under all conditions. Look up the factory specifications in the service manual. Then adjust your unit as required to bring it within spec.

Close to stock. If the mechanical advance has been altered from factory, then you might want to alter the vacuum advance to keep the timing for cruising on the highway the same as the factory had established as best. With a '70s mopar, you may wish to experiment slightly as they may have somewhat adjusted the vacuum advance to reduce certain emissions while driving. Also EGR equipped vehicles can be expected to have slightly different burn rates due to the addition of hot O2.

For a modified or custom setup, one can follow Direct Connection's guidelines. In my opinion it is best to use the guidelines from the era of the Chrysler built distributors. Summarized here from Mopar Performance Instructions DCF-194:

A. Establish mechanical timing curve per guidelines. These are based on timing at 2600 - 2800 rpm. A few listed below.

> pre-'89 A/LA iron, 35*, for newer heads, 32*

> B/RB iron 38* Indy Aluminum 35*

B. Measure the manifold vacuum while cruising (highway).

C. Adjust the vacuum advance to get the timing at 2600 rpm and the vacuum measured above:

A engines 50*

B/RB engines 56*

Whether this is done on the engine or on a distributor machine, a vacuum pump will be needed. For example, if the car cruises with manifold vacuum of 17", then bring the engine to 2600 rpm and adjust the vacuum can so the timing reads at 50* (for a small block).

However the MP procedure focuses only on the timing while cruising. If one is willing to adjust both the vacuum advance's limit and when it comes into play, additional tuning is possible. Obviously this requires some experimentation. This additional step seeks to determine when the vacuum advance should begin.

Tune the vacuum advance to equal zero before fuel enrichment is needed. For a Holley, the manifold vacuum of enrichment is known by the power valve stamping. For example, a 1967 440 cid with Holley came with 6.5 power valve. Therefore, the fuel mixture for these engines got richer as the manifold vacuum dropped below 6.5"Hg. We would expect there to be no vacuum advance as the mixture richens up and not surprisingly the service manual shows these engines had no vacuum advance under 8.5 to 9.2" of vacuum.

Too much vacuum advance;

At part throttle and moderate load (acceleration or uphill) will be heard as pinging or gurgling.

At light cruising will feel like "trailer hitching" or "fish biting".

The spark plugs are a good indicator of detonation as well as combustion. Examining the plugs is a good practice.

As timing works hand in glove with both the fuel curve and combustion efficiency, its very helpful to look at the fuel curves. The next post will touch on that.

Part 3. Air-Fuel Ratios and Vacuum Advance

The purpose of adding vacuum advance is to match the slower burning leaner mixes. Ideally, vacuum advance should go away when the engine needs enrichment. Enrichment may be anywhere from 60% to 90% max power depending on the engine and drivetrain.

Below is a curve showing the most efficient fuel air ratio for a given load.

F = Fuel/Air ratio. AFR = 1/F

In this example from Larew (details here), enrichment is need around 60 to 70% load, which might equate to vacuum of 9 to 12 "Hg. So, lets say this is the case, and we find a PV or step up around 10.5 works best. So we would want the vacuum advance to go away as vacuum drops near 10.5"

As a real life examples, we can look to various factory engines. In the previous post I used the non-hi performance 1967 440 cid engines with a power valve opening around 6.5" Hg.

However the well known original Holley 3310 carburetors came with 10.5 power valves (primary side) and 8.5" (secondary side). Presumably GM determined that engine had a fuel curve similar to Larew's and needed to go richer earlier due to camshaft, heads, or other factors.

One can test for the best part throttle enrichment points but it is relatively time consuming. One method is by "crowding" vacuum readings with greater and greater throttle openings. Using the best time (or acceleration) to determine the vacuum reading that requires enrichment. Urich and Fisher describe this method for road race tuning in Holley Carburetor and Manifolds. A really good dyno operator, with a load cell dyno, and familiarity with this type of testing should be able to produce similar results. A very very few independent operators have 4-gas and 5-gas analyzers along with the dyno.* This may be the best method but is out of reach for most of us.

*edit: Dug out some of the references to using a gas bench and the main measurement needed for this is nitrous oxides. From one of the "very very few" mentioned above:

"The purpose of the power valve selection is to enrichen the mixture prior to the combustion temperatures going too high. To set a powervalve correctly requires a NOx sensor. Different engine combinations need fuel enrichment at different power levels." and "All that matters is the combustion temperature doesn't get too high and you measure that by measuring Oxides of nitrogen ie NOx. Anytime the powervalve is activated prior to being necessary its wasting fuel."

Bruce "Shrinker" Robertson. post #4 "Another Power Valve Question" archived Innovate Motorsports forum

Slight OT, but perhaps of interest to some is an in depth discussion of NOx formation and performance tuning. Using NOx for performance tuning. - Speed Talk

Timing guidelines from page 2 of Mopar Performance Instruction sheet DCF-194