basic rebuild ... possible?

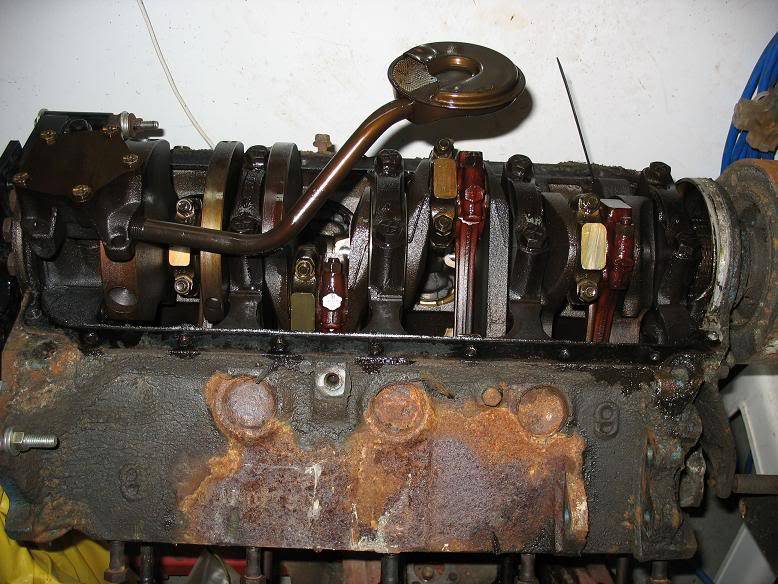

Well thanks a lot for all the infos again. Four pistons are now out of the block, and I have check the most thing I could until now. One of the four cylinder as little notch at top that you can feel the the finger nail. The 3 others seems much better. I also started with cylinder #3, this one was reading 70-80 psi, turns out that the 2 rings are stuck close tight. Not the 3 other cylinder.

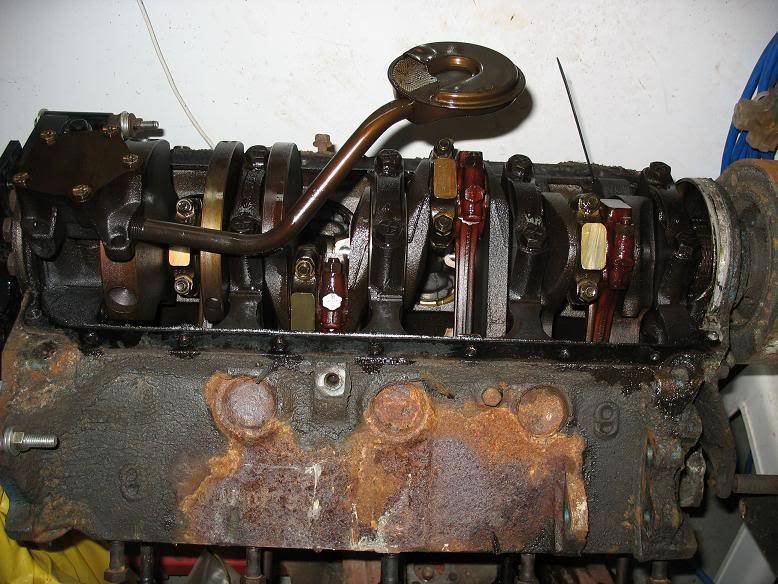

So I took some info at a good reputation machine shop in my area, and will start with having the block acid wash (migth be something else!!!), and having them check the whole block (if it need machining for the cylinder, crank and cam).

Last question .... any idea of what could create that red color on the rod...I scratched it with a knife, it is no paint ... and the magnet really stick to the rod.

Well thanks a lot for all the infos again. Four pistons are now out of the block, and I have check the most thing I could until now. One of the four cylinder as little notch at top that you can feel the the finger nail. The 3 others seems much better. I also started with cylinder #3, this one was reading 70-80 psi, turns out that the 2 rings are stuck close tight. Not the 3 other cylinder.

So I took some info at a good reputation machine shop in my area, and will start with having the block acid wash (migth be something else!!!), and having them check the whole block (if it need machining for the cylinder, crank and cam).

When you talk circular wear ... my guess it is what it should look like. The lifter in my 360 are all like this one.66dartgt said

Last question .... any idea of what could create that red color on the rod...I scratched it with a knife, it is no paint ... and the magnet really stick to the rod.