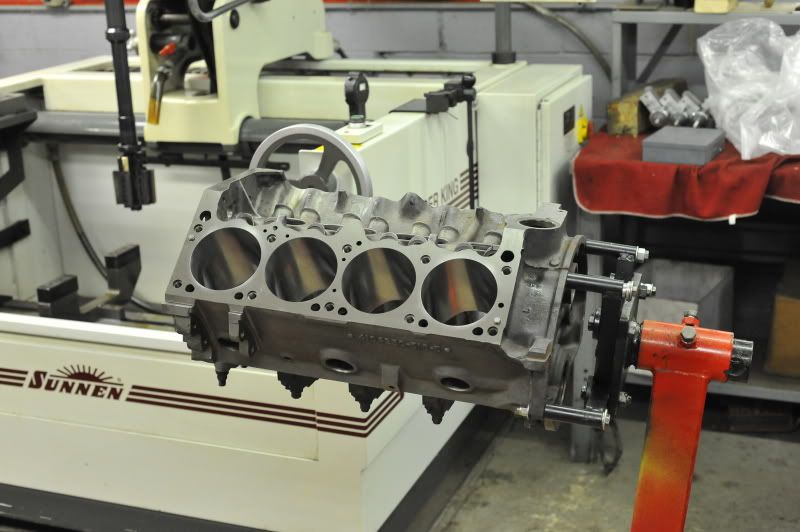

<<<<<430 cube small block mopar build>>>>>

WHOO HOO!

Got it honed and on a stand today - It was nice to watch an expert take the time to make things perfect today - Neal was taking the time to get absolutely no taper in the bore and have all of them dead on - the dial bore gauge reads to the ten thousands of an inch and i got to inspect the bores before we moved on - well I had nothing to complain about - thats for sure!

The CNC gets things close, but a bore or two were tighter at the top or bottom, ( we are still talking tenths) and Neal got it dead on balls straight!

We had the eddy head on one side and the hone plate on the side we were working on, with the head gaskets in place - the mains were torqued down - This loads the block like it will be when it is assembled.

We used two grits of stone and a plateau hone at the end.

The image was after the jet wash and after I crc'd the machined surfaces.

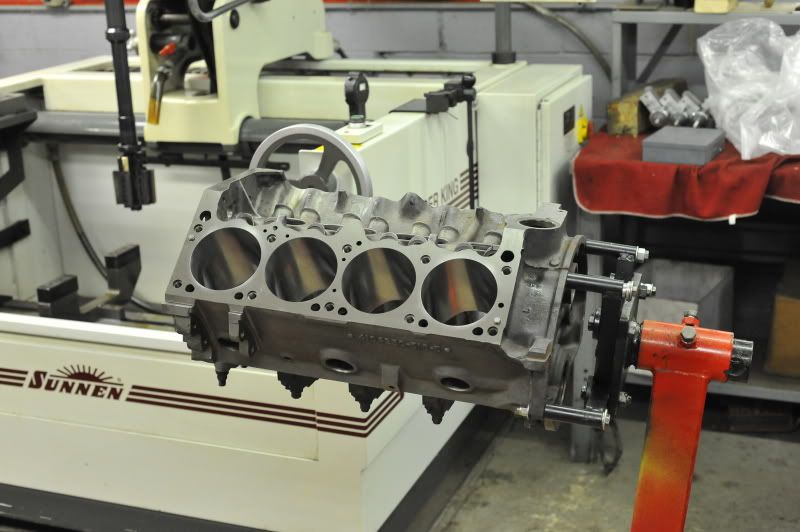

WHOO HOO!

Got it honed and on a stand today - It was nice to watch an expert take the time to make things perfect today - Neal was taking the time to get absolutely no taper in the bore and have all of them dead on - the dial bore gauge reads to the ten thousands of an inch and i got to inspect the bores before we moved on - well I had nothing to complain about - thats for sure!

The CNC gets things close, but a bore or two were tighter at the top or bottom, ( we are still talking tenths) and Neal got it dead on balls straight!

We had the eddy head on one side and the hone plate on the side we were working on, with the head gaskets in place - the mains were torqued down - This loads the block like it will be when it is assembled.

We used two grits of stone and a plateau hone at the end.

The image was after the jet wash and after I crc'd the machined surfaces.