The I'm-Learning-As-I-Go 1965 Valiant Post

In 2008, had some issues with the pushbutton 904 trans. Unfortunately, don't have any pics, but Bob had newer style 904 from the Slant he yanked from his 71 Dart. He brought it over, and it would not line up with the earlier block. We ended up pulling the engine completely and dropping in the 71 Slant block and trans. It required some modifications to get it to fit, as the later trans had a slightly different shape than the pushbutton. We chucked up the transmission mount into a vise and took a sawzall to various parts of the plate metal.

During the test drive, when the pedal was given heavy gas, the engine would starve and stall out until your foot hit the bottom of the stroke, at which point it would roar.

I was also having some issues with the parking brake - no matter how tight I would make it, it would not cinch up. I figured that the cable was binding in the housing somewhere. Some of the slantsix.org guys suggested yanking the cables and spraying lubricant into the housing.

I was planning to address all these issues... and in late 2008, the economy bombed. I lost my job, my home (had to move back in with the parents), and any semblance of financial stability for the next 3 years. The car sat.

And sat.

This was the Valiant about 6 months ago.

Every time I'd leave the house, it would depress me to see this slowly happening, and not be able to do anything about it. Recently got a new job that pays me a bit better, so had a little more disposable cash to throw at this project.

But rust is everywhere.

I don't know what it is about Mopars, but they all rust in the same places. The worst rust on the car is near the rear window on the drivers side, and at the top of the firewall where the air and rain enter the vents.

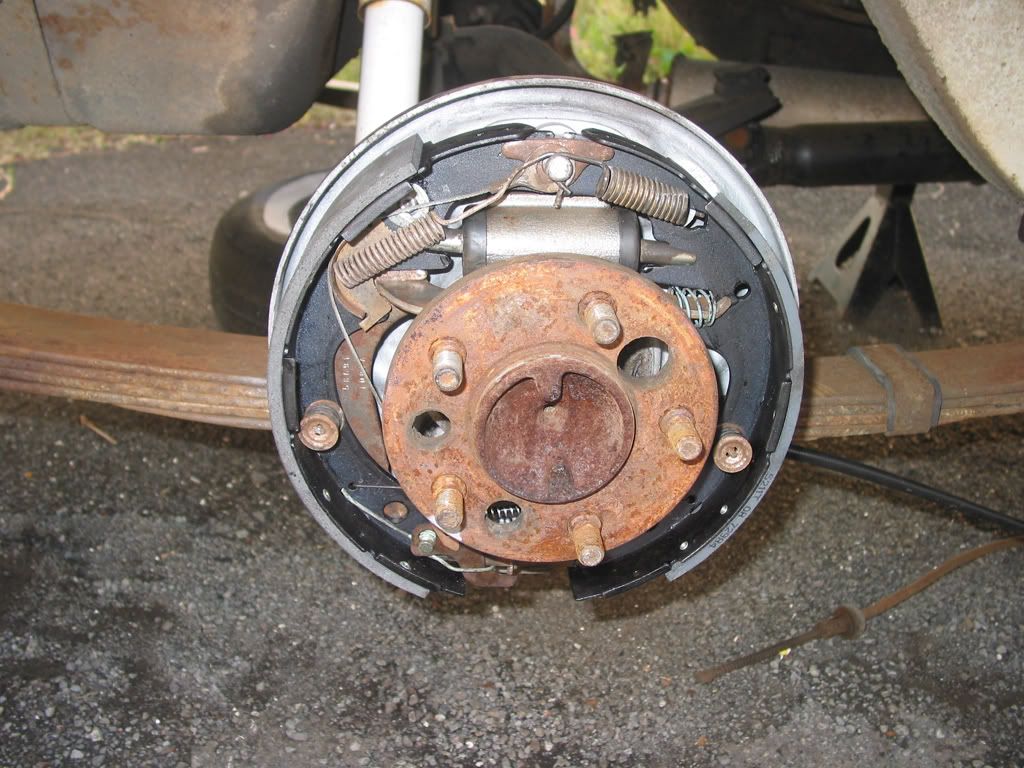

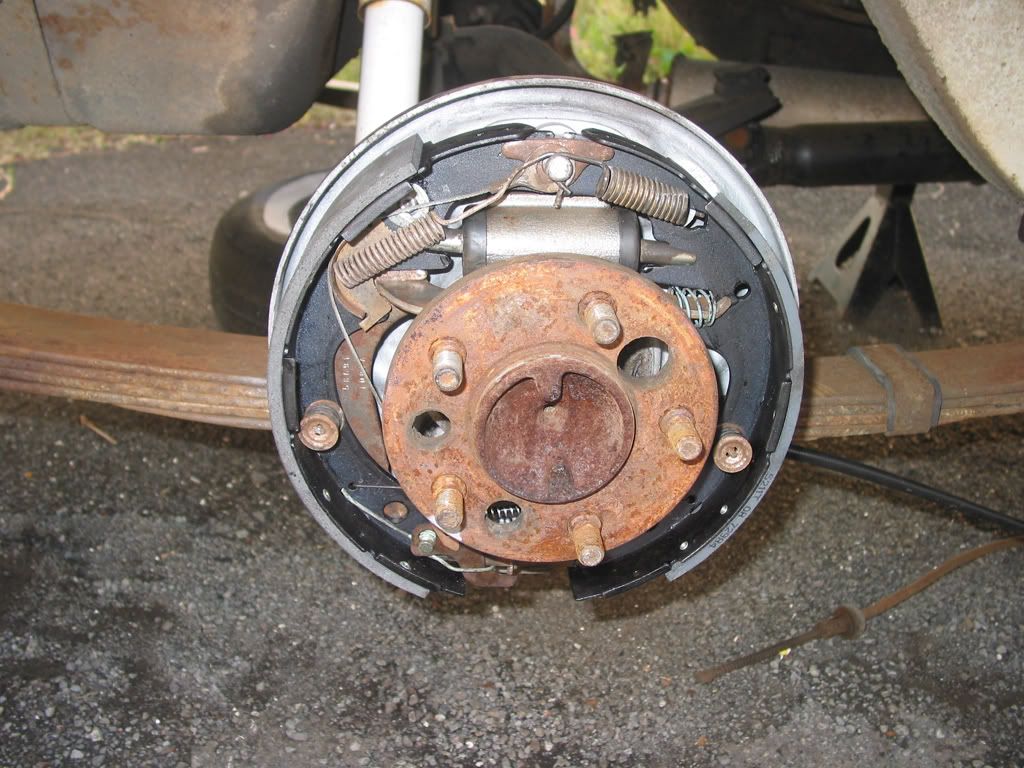

The first thing I started working on was fixing the e-brake issue. I yanked all the cables, except the release cable, ordered some new ones from Rock Auto. When I took off the drums, I noticed the shoes were worn pretty badly. So I bought some fresh new shoes.

Cleaned and wire brushed the parts and backing plates. And installed some new wheel cylinders in there since I had everything apart.

Had some trouble putting back the spring-loaded rentention pins on the shoes. Used vise grips to hold and push the cap on the springs per oklacarcollector's advice, and some other great advice came from StrokerScamp:

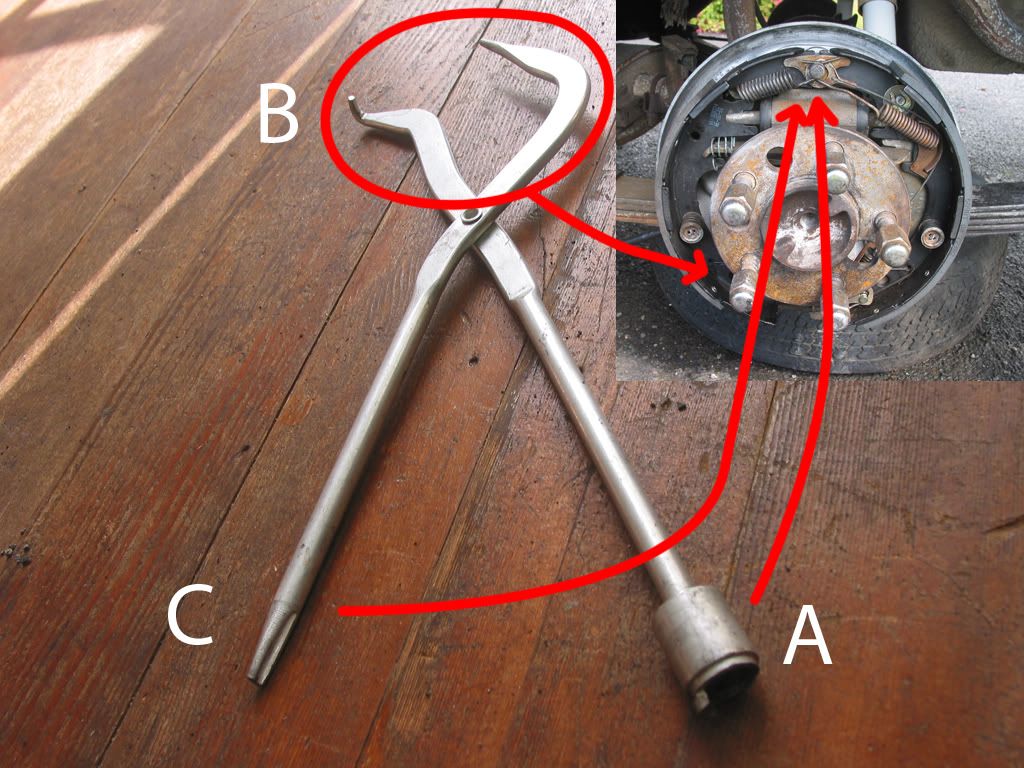

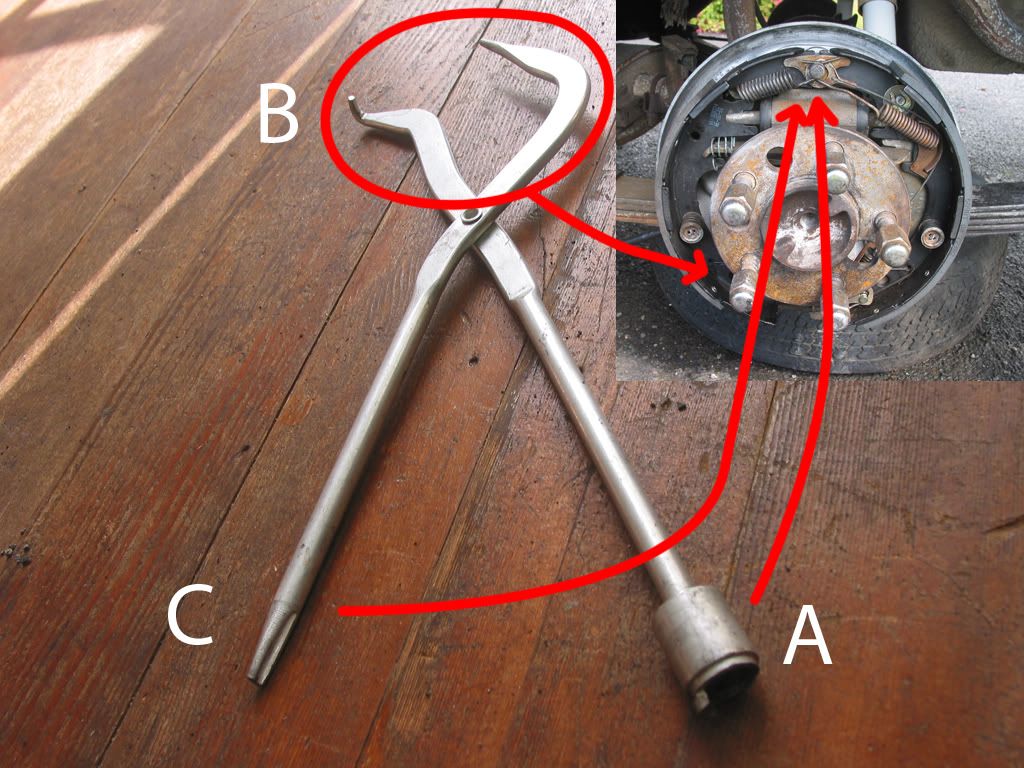

"I have a drawer full of brake tools. If you're gonna own a old car, get the right tools to work on it with."

Noted. Once I bought a brake tool, putting it back together was a snap.

This is the tool I used.

A - Removes the springs at the top of the brakes;

B - Is helpful when reinstalling the bottom spring that holds the two shoes together; and

C - Helps you leverage the top springs back onto the center pin.

BTW, these are my two best friends that are helping me during this build:

PB Blaster is the best thing for getting anything lubed or unstuck.

And OSPHO for the rusty stuff.

While I was waiting for it to stop raining, I used my rotary tool and ground off all the rust and bumpy castings off the drums.

Hit both with a coat of OSPHO, washed them off, threw on some VHT paint:

Gonna leave the drums off the car for now. They need to be recut.

In 2008, had some issues with the pushbutton 904 trans. Unfortunately, don't have any pics, but Bob had newer style 904 from the Slant he yanked from his 71 Dart. He brought it over, and it would not line up with the earlier block. We ended up pulling the engine completely and dropping in the 71 Slant block and trans. It required some modifications to get it to fit, as the later trans had a slightly different shape than the pushbutton. We chucked up the transmission mount into a vise and took a sawzall to various parts of the plate metal.

During the test drive, when the pedal was given heavy gas, the engine would starve and stall out until your foot hit the bottom of the stroke, at which point it would roar.

I was also having some issues with the parking brake - no matter how tight I would make it, it would not cinch up. I figured that the cable was binding in the housing somewhere. Some of the slantsix.org guys suggested yanking the cables and spraying lubricant into the housing.

I was planning to address all these issues... and in late 2008, the economy bombed. I lost my job, my home (had to move back in with the parents), and any semblance of financial stability for the next 3 years. The car sat.

And sat.

This was the Valiant about 6 months ago.

Every time I'd leave the house, it would depress me to see this slowly happening, and not be able to do anything about it. Recently got a new job that pays me a bit better, so had a little more disposable cash to throw at this project.

But rust is everywhere.

I don't know what it is about Mopars, but they all rust in the same places. The worst rust on the car is near the rear window on the drivers side, and at the top of the firewall where the air and rain enter the vents.

The first thing I started working on was fixing the e-brake issue. I yanked all the cables, except the release cable, ordered some new ones from Rock Auto. When I took off the drums, I noticed the shoes were worn pretty badly. So I bought some fresh new shoes.

Cleaned and wire brushed the parts and backing plates. And installed some new wheel cylinders in there since I had everything apart.

Had some trouble putting back the spring-loaded rentention pins on the shoes. Used vise grips to hold and push the cap on the springs per oklacarcollector's advice, and some other great advice came from StrokerScamp:

"I have a drawer full of brake tools. If you're gonna own a old car, get the right tools to work on it with."

Noted. Once I bought a brake tool, putting it back together was a snap.

This is the tool I used.

A - Removes the springs at the top of the brakes;

B - Is helpful when reinstalling the bottom spring that holds the two shoes together; and

C - Helps you leverage the top springs back onto the center pin.

BTW, these are my two best friends that are helping me during this build:

PB Blaster is the best thing for getting anything lubed or unstuck.

And OSPHO for the rusty stuff.

While I was waiting for it to stop raining, I used my rotary tool and ground off all the rust and bumpy castings off the drums.

Hit both with a coat of OSPHO, washed them off, threw on some VHT paint:

Gonna leave the drums off the car for now. They need to be recut.