Charger

The engines are now moved out of the way of work on the car. We're still waiting for another blower idler pulley bracket from BDS. - Don't want to attempt to set up alternator or power steering brackets until we've got the supercharger belt set up.

This photo is of the notch made in the frame on the passenger side. This is where the new front leaf spring hanger will be welded in.

IT ROLLS!!!!! - With the rear end re-attached the Charger is finally on all fours again.

The decision was made to weld all new seams solid in the flooring. The reasoning behind it was to make the car as solid as possible to help withstand the torque produced by the coming blown 512 stroker motor.

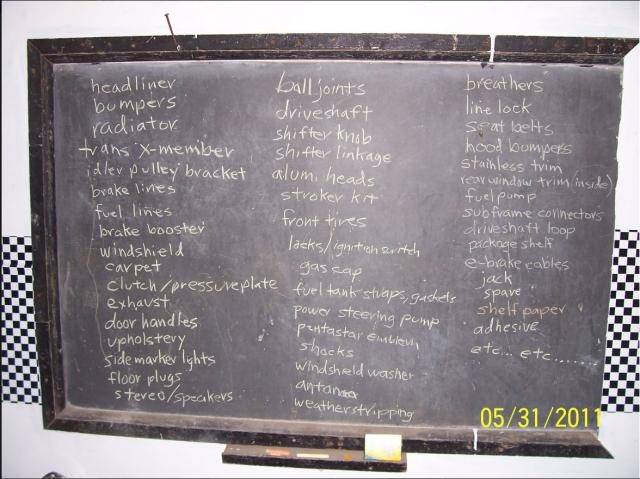

- just a partial list of things yet to be purchased...

We got a rear seat core from Zimmerman out of Rising City. It will still have to have it's frame modified to mate with the new widened wheel wells before going to the upholstery shop.

In this photo you can see the passenger side's front spring hanger welded in place.

Once the widened wheel wells have had their welds ground down and a sealing coat of POR-15 applied, it will be hard to tell from inside the trunk that they've been modified.

Either we're good or really lucky. The tires seem to be perfectly centered in the widened wheel wells. New Keystones clear the new disc brakes. After the long winter, progress is finally starting to show again.

After coming home from 4 years in the Army, one of the first things Spence did was start working on the Charger again. We stripped off the upholstery and padding from the rear seat we'd gotten so that we could modify the frames to fit against the newly widened wheel tubs.

The engines are now moved out of the way of work on the car. We're still waiting for another blower idler pulley bracket from BDS. - Don't want to attempt to set up alternator or power steering brackets until we've got the supercharger belt set up.

This photo is of the notch made in the frame on the passenger side. This is where the new front leaf spring hanger will be welded in.

IT ROLLS!!!!! - With the rear end re-attached the Charger is finally on all fours again.

The decision was made to weld all new seams solid in the flooring. The reasoning behind it was to make the car as solid as possible to help withstand the torque produced by the coming blown 512 stroker motor.

- just a partial list of things yet to be purchased...

We got a rear seat core from Zimmerman out of Rising City. It will still have to have it's frame modified to mate with the new widened wheel wells before going to the upholstery shop.

In this photo you can see the passenger side's front spring hanger welded in place.

Once the widened wheel wells have had their welds ground down and a sealing coat of POR-15 applied, it will be hard to tell from inside the trunk that they've been modified.

Either we're good or really lucky. The tires seem to be perfectly centered in the widened wheel wells. New Keystones clear the new disc brakes. After the long winter, progress is finally starting to show again.

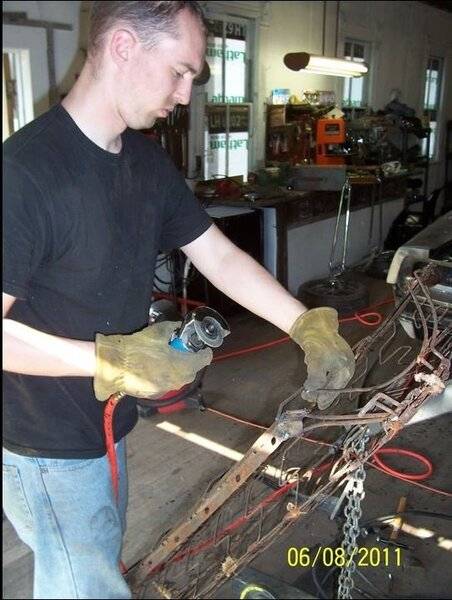

After coming home from 4 years in the Army, one of the first things Spence did was start working on the Charger again. We stripped off the upholstery and padding from the rear seat we'd gotten so that we could modify the frames to fit against the newly widened wheel tubs.