Charger

In addition to having to cut and re-weld the frames, we had to descale all of the rust off of them

Here the frames are after being modified and coating them with paint. The next stop for them will be the upholstery shop.

The housing for the heater core/air conditioning has finally been removed from the interior. The decision to eliminate the air conditioning meant those components needed to be taken out of this housing.

Tucked up behind the air conditioner was another mouse hotel. This should be the last remnants of the Oklahoma mouse housing project.

Of course, there were openings through the firewall that accommodated the air conditioner. We'll have to weld and fill these.

In this pic, the holes have been welded. A little body filler and you'll never know they were there.

We scored another piece from Zimmerman (from Rising City). This should be the correct 4-speed transmission crossmember. It was entirely covered with rust, but after 40 minutes with the wire wheel and some black paint, it looks good as new.

Fiberglass mat is cut into strips that will be used to seal every weld seam in the car. The factories used a caulk-like seam sealer that would harden after a few years. By layering the POR-15 anti-rust paint with this fiberglass we should have a permanent seal.

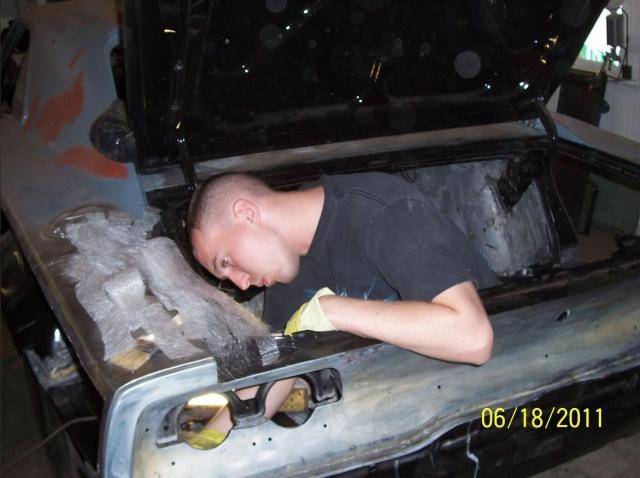

Working on the seams inside the trunk, first the welds are scoured with degreaser and then a metal prep is applied to give the POR-15 good adhesion.

Once the welded areas are prepped, a coat of POR-15 is applied followed by a strip of fiberglass and then another coat of the POR-15.

In addition to having to cut and re-weld the frames, we had to descale all of the rust off of them

Here the frames are after being modified and coating them with paint. The next stop for them will be the upholstery shop.

The housing for the heater core/air conditioning has finally been removed from the interior. The decision to eliminate the air conditioning meant those components needed to be taken out of this housing.

Tucked up behind the air conditioner was another mouse hotel. This should be the last remnants of the Oklahoma mouse housing project.

Of course, there were openings through the firewall that accommodated the air conditioner. We'll have to weld and fill these.

In this pic, the holes have been welded. A little body filler and you'll never know they were there.

We scored another piece from Zimmerman (from Rising City). This should be the correct 4-speed transmission crossmember. It was entirely covered with rust, but after 40 minutes with the wire wheel and some black paint, it looks good as new.

Fiberglass mat is cut into strips that will be used to seal every weld seam in the car. The factories used a caulk-like seam sealer that would harden after a few years. By layering the POR-15 anti-rust paint with this fiberglass we should have a permanent seal.

Working on the seams inside the trunk, first the welds are scoured with degreaser and then a metal prep is applied to give the POR-15 good adhesion.

Once the welded areas are prepped, a coat of POR-15 is applied followed by a strip of fiberglass and then another coat of the POR-15.