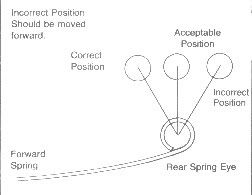

Perhaps this will provide a better perspective:

* The bottom of the shackle (that is attached to the rear of the leaf spring eye) should be angled down, behind the vehicle. Basically, behind the upper eye mount.

...and a pic is worth a thousand words:

Thanks for the pic! That is the way I had thought the rear shackles need to be set up. I'm glad

I'm set up correctly.