Another Mopar Off My Bucket List - Barracuda Fastback

Boy oh boy, I had really cringed when my son originally proposed the plan. He can be pretty persuasive. Because it's actually his car I never make the final decisions on direction. I'm still hoping that our final design will produce results. The boat designs I've seen use lake water to maintain a supply of cool water and I would think they'd be very efficient.

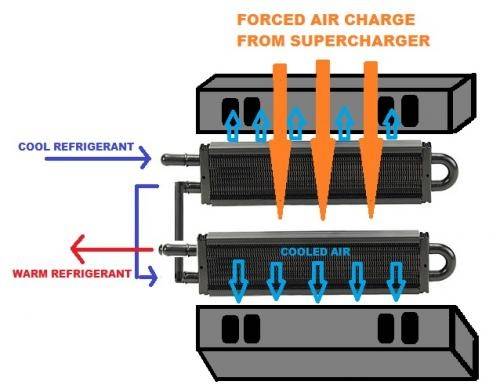

We had debated the benefit of running an intercooler and knew that most boosted engines see a big gain with them. One of the first things I told my son was that I thought the gain would be minimal on a system that relied upon a closed loop water recirculating design. I assumed that the temperature of the water would become warm and you wouldn't get much cooling effect. We speculated that a refrigerated version would be better capable of maintaining a cold flow.

My son contacted Steve Kinser of Iowa to pick his brain. Steve runs a blown alcohol hemi altered and drag boat. He runs a machine shop and had re-machined our 6-71 for us. His specialty seems to be working with blown aluminum block Keith Black Hemis. There must have been a dozen of them sitting around his shop the last time I was there. When my son described what we were planning he told him it was a good idea. He claimed that we'd see a horsepower increase with each degree cooler we could drop the intake charge. I don't know how specific my son was when he described our design.

Yesterday we switched gears a bit on our design. Instead of coiling aluminum tubing around the center supports by hand, we ordered a pair of copper tube/aluminum finned heat exchangers that should fit on each side of our supports. I had been pushing the potential added benefit of a finned design to my son. Although I still think we'll see a gain I did have concerns about restricting air flow and affecting fuel atomization. This intake has a very open plenum design which I hope will provide adequate flow capability even with the heat exchanger installed.

If we run our line in through the top fitting of one of these units and then have the bottom fitting loop into the bottom fitting of the second exchanger, we should be able to have it exit the manifold through the top fitting of the second exchanger.

The heat exchangers are made by a company named DERALE Performance.

The dimensions of each unit is 12-5/8" x 2-1/2" x 3/4". The width of the opening we've cut is already 3/4" wide and our opening length is 12". Our intake plenum is 3" tall. We may be adding some filler pieces to help direct flow after installing the coolers.

View attachment 259-13200.jpg

View attachment 259-13200B.jpg

View attachment Capture.JPG

Boy oh boy, I had really cringed when my son originally proposed the plan. He can be pretty persuasive. Because it's actually his car I never make the final decisions on direction. I'm still hoping that our final design will produce results. The boat designs I've seen use lake water to maintain a supply of cool water and I would think they'd be very efficient.

We had debated the benefit of running an intercooler and knew that most boosted engines see a big gain with them. One of the first things I told my son was that I thought the gain would be minimal on a system that relied upon a closed loop water recirculating design. I assumed that the temperature of the water would become warm and you wouldn't get much cooling effect. We speculated that a refrigerated version would be better capable of maintaining a cold flow.

My son contacted Steve Kinser of Iowa to pick his brain. Steve runs a blown alcohol hemi altered and drag boat. He runs a machine shop and had re-machined our 6-71 for us. His specialty seems to be working with blown aluminum block Keith Black Hemis. There must have been a dozen of them sitting around his shop the last time I was there. When my son described what we were planning he told him it was a good idea. He claimed that we'd see a horsepower increase with each degree cooler we could drop the intake charge. I don't know how specific my son was when he described our design.

Yesterday we switched gears a bit on our design. Instead of coiling aluminum tubing around the center supports by hand, we ordered a pair of copper tube/aluminum finned heat exchangers that should fit on each side of our supports. I had been pushing the potential added benefit of a finned design to my son. Although I still think we'll see a gain I did have concerns about restricting air flow and affecting fuel atomization. This intake has a very open plenum design which I hope will provide adequate flow capability even with the heat exchanger installed.

If we run our line in through the top fitting of one of these units and then have the bottom fitting loop into the bottom fitting of the second exchanger, we should be able to have it exit the manifold through the top fitting of the second exchanger.

The heat exchangers are made by a company named DERALE Performance.

The dimensions of each unit is 12-5/8" x 2-1/2" x 3/4". The width of the opening we've cut is already 3/4" wide and our opening length is 12". Our intake plenum is 3" tall. We may be adding some filler pieces to help direct flow after installing the coolers.

View attachment 259-13200.jpg

View attachment 259-13200B.jpg

View attachment Capture.JPG