The Great Pumpkin - '71 Duster

Alright, little more progress on the engine build. Got the oil rings done. No more ring filing! Got half of the pistons on the rods today but ran out of time to finish the job. I was cursing the Spiro locks but once I figured 'em out they were a piece of cake.

The oil rings took a long time to do since there are two oil scraper rails per each cylinder. They are also steel so they take a while to file to spec.

I had to read up on this a little. There is no real exact dimension for these like .045" per inch of bore but rather a minimum clearance of .015". I talked to Total Seal and they said .025" is good for my application so that's where I ended up.

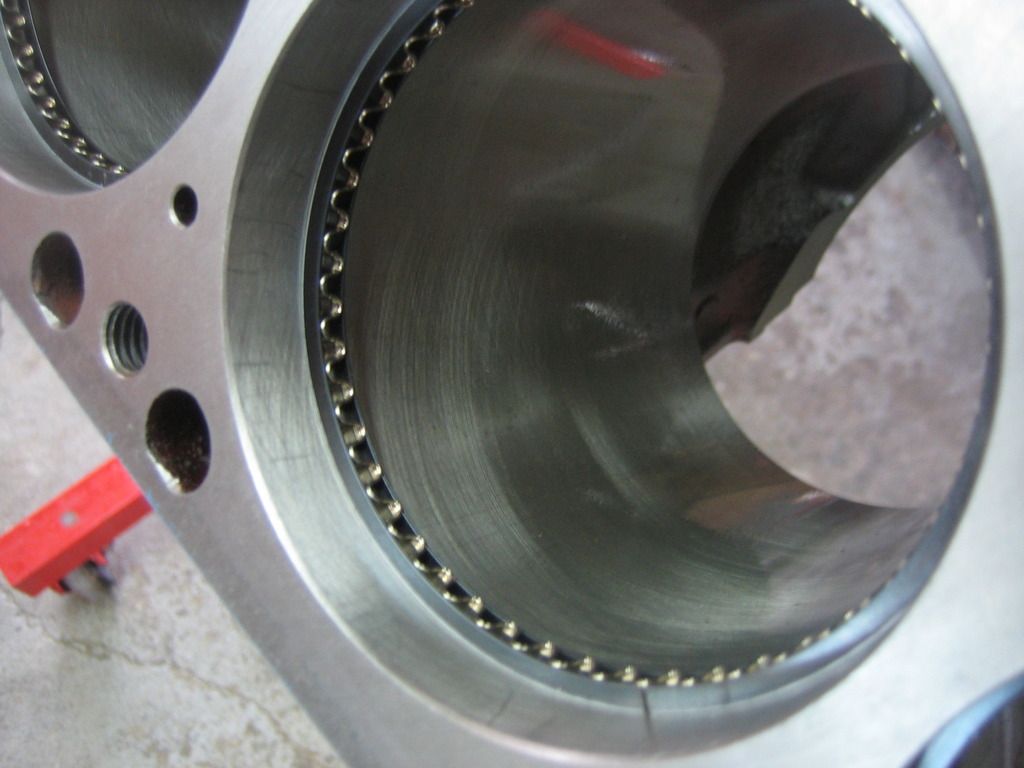

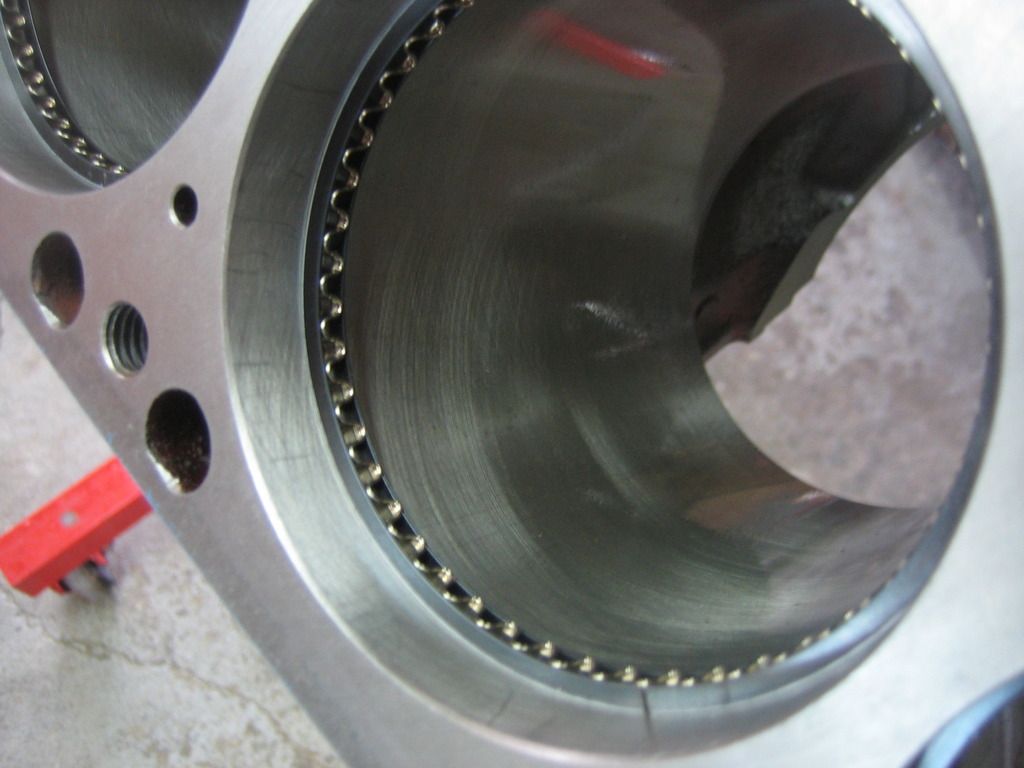

So here is a shot of the oil rings all done and MATCHED TO THEIR BORES. After I was done, I put them in individual, labeled baggies to keep all the cylinders together. Everyone happy now? :D

So the spiro locks - until you figure out how to get them in, they really suck. I fumbled around with them for a long time, like over an hour. I felt like I was destroying the pin bore trying to wrangle them in. I watched videos and read forum posts for help but I could not get them in. I must have been hung over from my birthday BBQ on Saturday because I was not in the right frame of mind at all. I was at it from yesterday afternoon into the evening and gave up.

So after I was done with daddy duty this AM, I went back to it for a bit and was able to figure it out pretty quickly. First thing to do is pull them apart like a slinky - since that's kinda what they are, a coiled spring. So you pull it apart a little which makes it easier to slide the tip into the lock groove in the pin bore. Once it's firmly in the groove, you push the spring down with the tip of a small screwdriver while you sort of pull up on the end of it to make the concentric circles smaller. This allows you to force the spring into the groove. You work around in a circle with the screwdriver tip until it fully seats and snaps into place. It ain't coming out. Again, once you figure out the method, it takes 10 seconds to do them.

One also needs to be aware of which way to install the rods on the pistons. The rod has a larger chamfer on one side that goes towards the fillet on the crank journal while the smaller edge butts up against the other rod. Methinks it might be bad news if you got to the point where you fired up the engine with the rods installed wrong.

So here is the spiro lock pulled apart to ease installation.

Here is a rod and piston along side the little screwdriver I used to push the lock into the groove. Handling this stuff made made it really evident that these modern rods and pistons are so much lighter than OE stuff. It's kind of crazy how heavy the old stuff is.

Here's the rest of the left bank, ready for the next steps.

More to come.

Alright, little more progress on the engine build. Got the oil rings done. No more ring filing! Got half of the pistons on the rods today but ran out of time to finish the job. I was cursing the Spiro locks but once I figured 'em out they were a piece of cake.

The oil rings took a long time to do since there are two oil scraper rails per each cylinder. They are also steel so they take a while to file to spec.

I had to read up on this a little. There is no real exact dimension for these like .045" per inch of bore but rather a minimum clearance of .015". I talked to Total Seal and they said .025" is good for my application so that's where I ended up.

So here is a shot of the oil rings all done and MATCHED TO THEIR BORES. After I was done, I put them in individual, labeled baggies to keep all the cylinders together. Everyone happy now? :D

So the spiro locks - until you figure out how to get them in, they really suck. I fumbled around with them for a long time, like over an hour. I felt like I was destroying the pin bore trying to wrangle them in. I watched videos and read forum posts for help but I could not get them in. I must have been hung over from my birthday BBQ on Saturday because I was not in the right frame of mind at all. I was at it from yesterday afternoon into the evening and gave up.

So after I was done with daddy duty this AM, I went back to it for a bit and was able to figure it out pretty quickly. First thing to do is pull them apart like a slinky - since that's kinda what they are, a coiled spring. So you pull it apart a little which makes it easier to slide the tip into the lock groove in the pin bore. Once it's firmly in the groove, you push the spring down with the tip of a small screwdriver while you sort of pull up on the end of it to make the concentric circles smaller. This allows you to force the spring into the groove. You work around in a circle with the screwdriver tip until it fully seats and snaps into place. It ain't coming out. Again, once you figure out the method, it takes 10 seconds to do them.

One also needs to be aware of which way to install the rods on the pistons. The rod has a larger chamfer on one side that goes towards the fillet on the crank journal while the smaller edge butts up against the other rod. Methinks it might be bad news if you got to the point where you fired up the engine with the rods installed wrong.

So here is the spiro lock pulled apart to ease installation.

Here is a rod and piston along side the little screwdriver I used to push the lock into the groove. Handling this stuff made made it really evident that these modern rods and pistons are so much lighter than OE stuff. It's kind of crazy how heavy the old stuff is.

Here's the rest of the left bank, ready for the next steps.

More to come.