Slant 6 Turbo 68Dart Project

Basically my idea involves a very simple setup that anyone could bolt to the slant and would fit under the stock manifold. But I haven't worked it out yet really. It's more up in my imagination than on paper at this point. I'd build 3. One would be for me, then the other two would be up for grabs I'd think.

Either way, I know it doesn't look like I'm working on this, but I promise I am. I went for a budget build and I think I accomplished that. I created a turbocharged slant in the driveway for about $1500. So that goal was definitly met - but now, I have been improving it, and with improvement comes more cost. I am basically replacing all the cheap components with more durable ones.

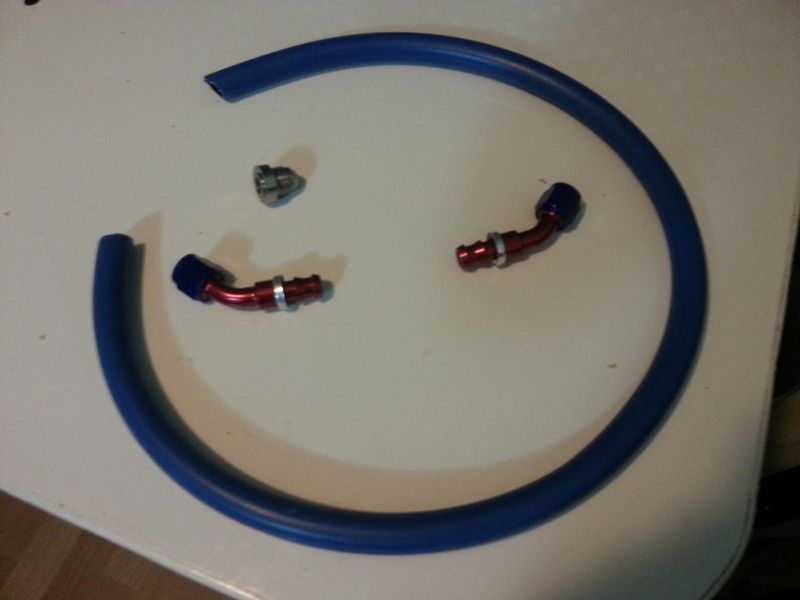

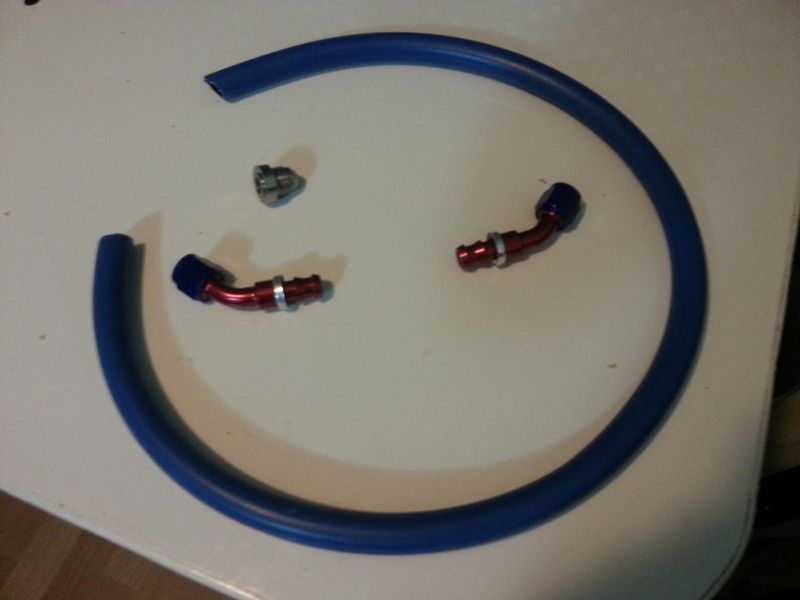

One of the systems i have ready to add is the oil cooler, and the 2nd line I ordered for it showed up in the mail. That system is all attached with -10an hardware.

I plan to drain the oil, setup the new improved oil sandwich system (I have figured out a way to do it unlike the original that was a total failure). Once that is set, i will of course be taking pictures of it. I like documenting everything I do, because besides those who read it whenever there's an update, someone on google is typing "slant six turbo" because they want to know how, and my slant does show up on the first page of results, and maybe that helps someone. It's one thing to say "I did this. Here it is done" and another to say "I did this... here's photos of what I did"

For example, I helped my dad replace the water pump and timing belt on his 1994 Toyota Celica and someone had posted pictures on a forum of exactly what to do to complete the whole process in dumbed down terms. That was way better than drawings in a service manual or haynes.

Anyway, back on track - once the oil is drained I will also be changing the system that bolts the oil return to the oil pan. I hunted around and located a steel -8an weld on fitting, and it will be going in place of the screw in one that turned to junk on that fateful drive. It's mostly improving on the farmer parts, with more durable and reliable ones.

I also got some 45* -8an fittings for the weld on, and for the bottom of the turbo, to replace the braided stainless and clamps i have now.

Then the other thing going in is the cooler, sandwich, and the -10 an push hoses and routing those. I may have to drill some holes in the radiator support frame, but i may have a way around that.

More to come - basically going to get oily.

Basically my idea involves a very simple setup that anyone could bolt to the slant and would fit under the stock manifold. But I haven't worked it out yet really. It's more up in my imagination than on paper at this point. I'd build 3. One would be for me, then the other two would be up for grabs I'd think.

Either way, I know it doesn't look like I'm working on this, but I promise I am. I went for a budget build and I think I accomplished that. I created a turbocharged slant in the driveway for about $1500. So that goal was definitly met - but now, I have been improving it, and with improvement comes more cost. I am basically replacing all the cheap components with more durable ones.

One of the systems i have ready to add is the oil cooler, and the 2nd line I ordered for it showed up in the mail. That system is all attached with -10an hardware.

I plan to drain the oil, setup the new improved oil sandwich system (I have figured out a way to do it unlike the original that was a total failure). Once that is set, i will of course be taking pictures of it. I like documenting everything I do, because besides those who read it whenever there's an update, someone on google is typing "slant six turbo" because they want to know how, and my slant does show up on the first page of results, and maybe that helps someone. It's one thing to say "I did this. Here it is done" and another to say "I did this... here's photos of what I did"

For example, I helped my dad replace the water pump and timing belt on his 1994 Toyota Celica and someone had posted pictures on a forum of exactly what to do to complete the whole process in dumbed down terms. That was way better than drawings in a service manual or haynes.

Anyway, back on track - once the oil is drained I will also be changing the system that bolts the oil return to the oil pan. I hunted around and located a steel -8an weld on fitting, and it will be going in place of the screw in one that turned to junk on that fateful drive. It's mostly improving on the farmer parts, with more durable and reliable ones.

I also got some 45* -8an fittings for the weld on, and for the bottom of the turbo, to replace the braided stainless and clamps i have now.

Then the other thing going in is the cooler, sandwich, and the -10 an push hoses and routing those. I may have to drill some holes in the radiator support frame, but i may have a way around that.

More to come - basically going to get oily.