The Great Pumpkin - '71 Duster

Geez, updates have been few and far between here lately. Not going to apologize since I didn't do anything wrong but I feel bad for 'not putting the time in'. That said, the engine is basically done save for a few things that have been really tough to get past.

Buying a truck certainly didn't help. The truck runs and drives OK but it is a project that lately I have been sinking more time into than the Duster. Maybe I needed a break from it for a while though, what with all the missteps and do-overs.

Regardless, I'm going to admit something here that has been eating at me - I am afraid of sealing up the intake on the 416.

There, I said it.

I don't know how to do it, actually. Where do you put the goop? Do I use the cork gaskets or use a mountain of silicone instead? If I use silicone, do I cut the little head gasket tabs off? And on and on. This is just procedural stuff but the questions are legitimate. I want to get it right and not have any leaks. I hate leaks.

But deeper than that, there is a gnawing feeling that once I finally do get this step completed, it's done. And that's when the second guessing starts. Did I degree the cam right? Did I set up the rocker arms right? What if the carb is way off when I fire it? I need to dyno it, I need to do this I need to do that. What could I have done wrong? Paralysis by analysis.

I basically gotta stop wussin' out and git 'er done.

The other major piece of trepidation I'm dealing with is the trans. I had the valve body apart and changed the pressure spring so I want to test it somehow before I put it behind my brand new motor. I called around looking for someone with a transmission dyno. Freddy Brown transmissions said they have one but basically could only check pressure but also said he they could 'make it shift'. Hmmm..

While agonizing over the intake gaskets, I did manage to gasket match the intake. It was really nice day so I broke out the burrs and started whittling. Not sure what I ended up with and may go back and touch it up again but I managed to create a small mountain of aluminum chips.

The port roofs and inside port walls needed the most material removal. Some of the roofs had almost a 1/8" mismatch between the gasket and port opening. The short side turn on the inside ports bulges out before it gets to the end of the runner so I ground that down until it was close to being even with the port outline. The floor did not need too much material removal. I did not go too far into the runners because I have short burrs. Only other work was to smooth out some of the sharper edges on the runner dividers and blend the carb throat into the lower plenum. I was leery of doing too much here so I only touched it up a few times and stopped.

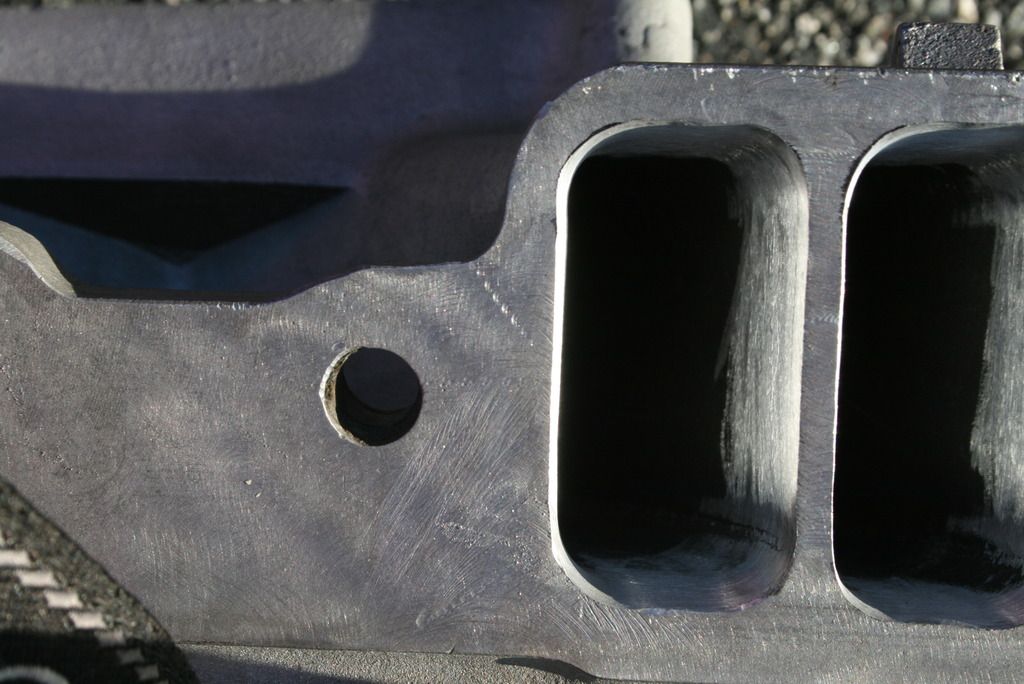

Here's the Strip Dominator gasket match in progress. The dark black areas are marker ink to check where I'm at.

Looking at the port roof from the bottom.

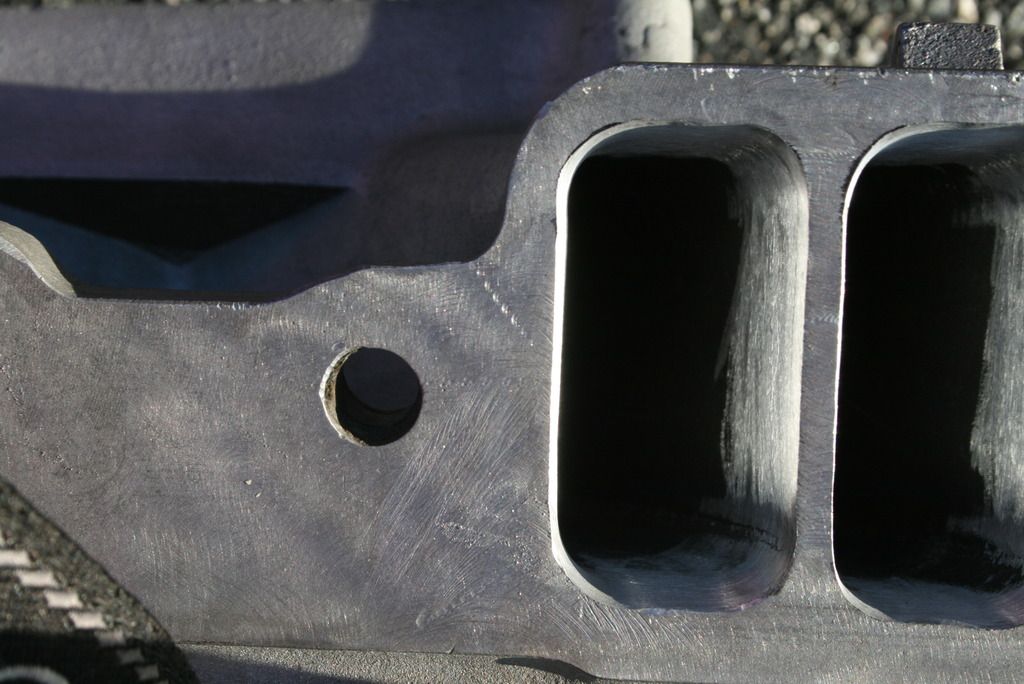

Here is a pic of the inside ports. The left most port wall had a good amount of material removed.

More.

My Dumore grinder makes quick work of soft aluminum.

I know I am not the only one who has ever struggled to complete a project like this. I am so damn close though. Just wish I could have gotten some seat time with it before winter.

More to come.

Geez, updates have been few and far between here lately. Not going to apologize since I didn't do anything wrong but I feel bad for 'not putting the time in'. That said, the engine is basically done save for a few things that have been really tough to get past.

Buying a truck certainly didn't help. The truck runs and drives OK but it is a project that lately I have been sinking more time into than the Duster. Maybe I needed a break from it for a while though, what with all the missteps and do-overs.

Regardless, I'm going to admit something here that has been eating at me - I am afraid of sealing up the intake on the 416.

There, I said it.

I don't know how to do it, actually. Where do you put the goop? Do I use the cork gaskets or use a mountain of silicone instead? If I use silicone, do I cut the little head gasket tabs off? And on and on. This is just procedural stuff but the questions are legitimate. I want to get it right and not have any leaks. I hate leaks.

But deeper than that, there is a gnawing feeling that once I finally do get this step completed, it's done. And that's when the second guessing starts. Did I degree the cam right? Did I set up the rocker arms right? What if the carb is way off when I fire it? I need to dyno it, I need to do this I need to do that. What could I have done wrong? Paralysis by analysis.

I basically gotta stop wussin' out and git 'er done.

The other major piece of trepidation I'm dealing with is the trans. I had the valve body apart and changed the pressure spring so I want to test it somehow before I put it behind my brand new motor. I called around looking for someone with a transmission dyno. Freddy Brown transmissions said they have one but basically could only check pressure but also said he they could 'make it shift'. Hmmm..

While agonizing over the intake gaskets, I did manage to gasket match the intake. It was really nice day so I broke out the burrs and started whittling. Not sure what I ended up with and may go back and touch it up again but I managed to create a small mountain of aluminum chips.

The port roofs and inside port walls needed the most material removal. Some of the roofs had almost a 1/8" mismatch between the gasket and port opening. The short side turn on the inside ports bulges out before it gets to the end of the runner so I ground that down until it was close to being even with the port outline. The floor did not need too much material removal. I did not go too far into the runners because I have short burrs. Only other work was to smooth out some of the sharper edges on the runner dividers and blend the carb throat into the lower plenum. I was leery of doing too much here so I only touched it up a few times and stopped.

Here's the Strip Dominator gasket match in progress. The dark black areas are marker ink to check where I'm at.

Looking at the port roof from the bottom.

Here is a pic of the inside ports. The left most port wall had a good amount of material removed.

More.

My Dumore grinder makes quick work of soft aluminum.

I know I am not the only one who has ever struggled to complete a project like this. I am so damn close though. Just wish I could have gotten some seat time with it before winter.

More to come.