VIOLENT\6

12 second N/A Slant 6?

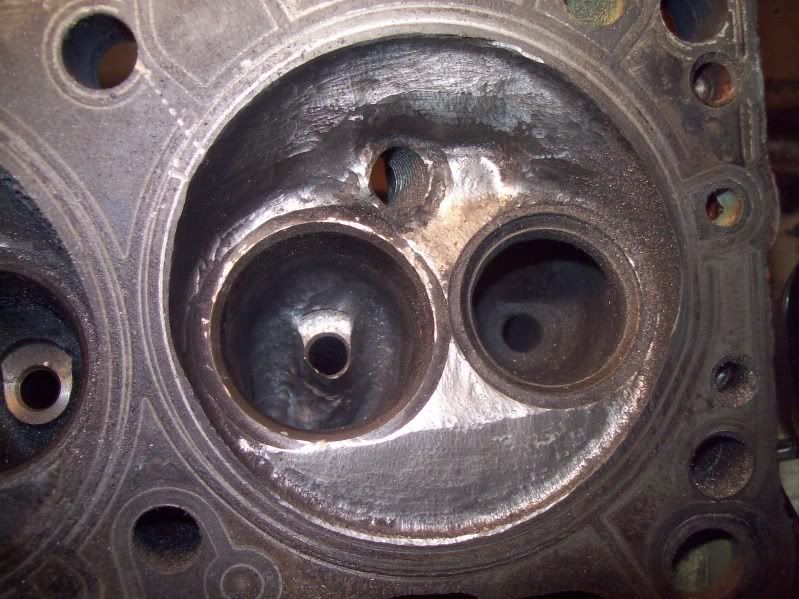

Yes, street engine. I have read that the intakes should not be polished smooth for the reasons you mentioned. Probably no smoother than 80 grit? I have also read that the exhaust side can be polished to a mirror finish for optimum evacuation and less chance of carbon build up. This is my first port job, so any advice will be much appreciated. Thanks.

That's the way I would do it.

not polish!

not polish!