Heater box cable questions

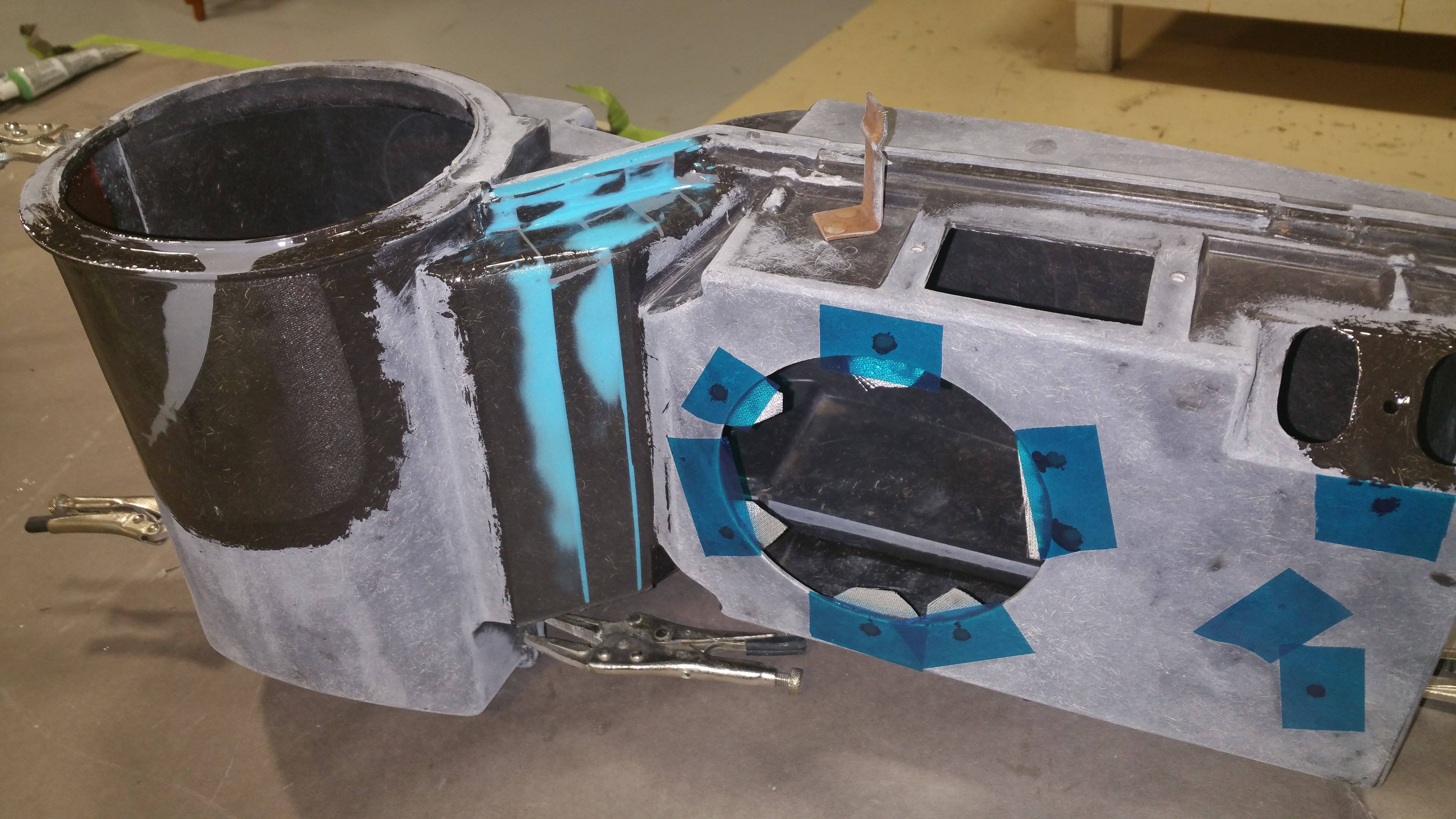

- Heater box clamshell was so warped on one end i had to perform surgery to unwarp it. 47 year old fiberglass if nothing else is brittle as hell. I figured out where to make the cuts with an air operated whiz wheel, then vise grip clamped it together to make it hold its correct shape, put aluminum tape on the inside temporarily, and filled the outside at the top with JB weld and cured it with a heat lamp, after that i sanded the JB weld down, and added the blue epoxy filler putty. Once that was dry i shaped it, and i added fiberglass cloth and resin on the inside and outside where the cuts are and reclamped it together until it all dries, then its back to sanding some more and prep for paint. I used a mould release between the 2 halves so they can be taken back apart.