Another Mopar Off My Bucket List - Barracuda Fastback

We didn't get everything done we wanted today.

Changing out the power steering pump wasn't too bad. The chrome one was identical except for the low pressure line inlet. An additional 6" of rubber hose took care of that. We did run into a problem with the pulley. Although I hadn't noticed it before we swapped it onto the new pump, it had a horrible wobble to it.

We pulled it back off and saw that the key hadn't stayed in the shaft groove. I hoped that was all that was wrong but it still wobbled badly after replacing the key. My guess is that the pulley was bent before and the wobble may have caused the seal to go out. We ended up putting the new billet aluminum pulley on that had been slated for the Charger. The original pulley was 6&3/4" in diameter. The aluminum pulley was only 6". We had to run to the parts store for a shorter belt.

_______________________________________________________________________________________

Before dropping the gas tank we disconnected the feed line to the throttle body and used the electric pump to transfer the fuel into 5 gallon jugs. Everything was going OK until I pulled the rubber return line hose off the tank. I was lying directly beneath it and gas gushed out straight up my nose and into my eyes. I'd been cautious when I disconnected the feed line and stayed off to the side. There wasn't even a single drip when it came apart. I guess I let my guard down on that second line. I stumbled to the house as fast as possible and flushed my eyes out at the kitchen sink. The burning stopped after about 5 minutes. I thought the damage was going to be much worse.

The rest of the tank removal went smoothly. Even though we'd used the electric pump to empty it there was still a few gallons left below the pickup filter. We added the rest with the other gas in our jugs.

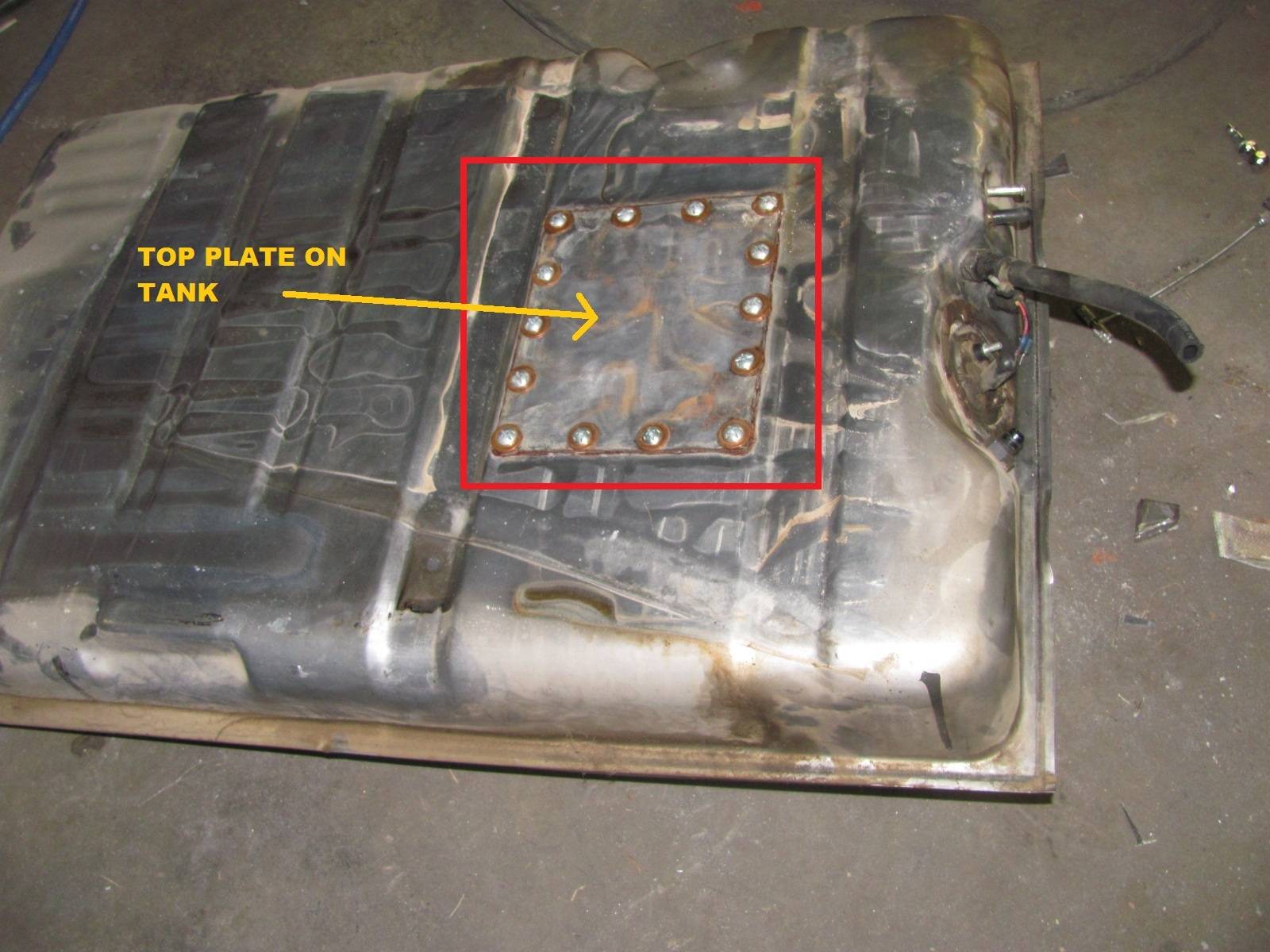

It was hot & muggy so we carried the tank into the garage where we ran the air conditioning to fix the leaks. There wasn't any sign that gas had been coming from the sending unit opening so we concentrated on the top cover plate. Whatever sealant Spence had used last didn't seal and the cork gasket he made was too thin (1/16") to make up the height of the nutserts. We went back to the parts store and picked up some 1/8" cork and a tube of #80016 Permatex. It's the only non-hardening sealant we could find that was resistant to fuel.

The high pressure fitting on the tank wasn't tight enough to ensure a decent seal so we tightened it before re-assembling the cover. I'm fairly confident we've got a good seal there now.

Next we checked the filler tube gasket and found that it had cracked from age. We didn't have a a spare but we ordered a new one from JEGS and are hoping it'll be here in a few days. Meanwhile the tank will have to wait.

I think we'll tear the cluster out tomorrow.

We didn't get everything done we wanted today.

Changing out the power steering pump wasn't too bad. The chrome one was identical except for the low pressure line inlet. An additional 6" of rubber hose took care of that. We did run into a problem with the pulley. Although I hadn't noticed it before we swapped it onto the new pump, it had a horrible wobble to it.

We pulled it back off and saw that the key hadn't stayed in the shaft groove. I hoped that was all that was wrong but it still wobbled badly after replacing the key. My guess is that the pulley was bent before and the wobble may have caused the seal to go out. We ended up putting the new billet aluminum pulley on that had been slated for the Charger. The original pulley was 6&3/4" in diameter. The aluminum pulley was only 6". We had to run to the parts store for a shorter belt.

_______________________________________________________________________________________

Before dropping the gas tank we disconnected the feed line to the throttle body and used the electric pump to transfer the fuel into 5 gallon jugs. Everything was going OK until I pulled the rubber return line hose off the tank. I was lying directly beneath it and gas gushed out straight up my nose and into my eyes. I'd been cautious when I disconnected the feed line and stayed off to the side. There wasn't even a single drip when it came apart. I guess I let my guard down on that second line. I stumbled to the house as fast as possible and flushed my eyes out at the kitchen sink. The burning stopped after about 5 minutes. I thought the damage was going to be much worse.

The rest of the tank removal went smoothly. Even though we'd used the electric pump to empty it there was still a few gallons left below the pickup filter. We added the rest with the other gas in our jugs.

It was hot & muggy so we carried the tank into the garage where we ran the air conditioning to fix the leaks. There wasn't any sign that gas had been coming from the sending unit opening so we concentrated on the top cover plate. Whatever sealant Spence had used last didn't seal and the cork gasket he made was too thin (1/16") to make up the height of the nutserts. We went back to the parts store and picked up some 1/8" cork and a tube of #80016 Permatex. It's the only non-hardening sealant we could find that was resistant to fuel.

The high pressure fitting on the tank wasn't tight enough to ensure a decent seal so we tightened it before re-assembling the cover. I'm fairly confident we've got a good seal there now.

Next we checked the filler tube gasket and found that it had cracked from age. We didn't have a a spare but we ordered a new one from JEGS and are hoping it'll be here in a few days. Meanwhile the tank will have to wait.

I think we'll tear the cluster out tomorrow.