340 X Head Valve Options

Well, I mocked up the valves in the head next to the old valves and measured my current spring install height. With the valves sitting in the old valve seats I have 1.62" spring install height on the intake and 1.58" spring install height on the exhaust. I am aiming for 1.80" install height. So as of now I am going to see if I can set the valves .050" deeper than the way they sit now, take another .050" off the spring cup (unless I will hit water) and also remove the Hemi spring damper that has an additional .050 clip on the bottom of the spring. That would net me an install height of 1.77" on the intake and 1.73" on the exhaust. Seems very possible. I will know more once the guides are set and valve job is complete. Then we can actually measure the real spring install height. I need to physically measure these springs to figure out their open and closed pressures.

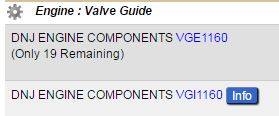

I found 5.7 Hemi valve guides for the 5/16 valve stems on RockAuto for less than $2.00 each. I also ordered hardened exhaust seats. This way I will have all the parts needed to do the valve job and will eliminate any head scratching at the machine shop.

I am considering doing the valve job and porting work backwards. Getting the guides and valve work completed first and then start porting, using clay or something to cover the valve seats. Not sure if anybody else has tried doing it that way.

Well, I mocked up the valves in the head next to the old valves and measured my current spring install height. With the valves sitting in the old valve seats I have 1.62" spring install height on the intake and 1.58" spring install height on the exhaust. I am aiming for 1.80" install height. So as of now I am going to see if I can set the valves .050" deeper than the way they sit now, take another .050" off the spring cup (unless I will hit water) and also remove the Hemi spring damper that has an additional .050 clip on the bottom of the spring. That would net me an install height of 1.77" on the intake and 1.73" on the exhaust. Seems very possible. I will know more once the guides are set and valve job is complete. Then we can actually measure the real spring install height. I need to physically measure these springs to figure out their open and closed pressures.

I found 5.7 Hemi valve guides for the 5/16 valve stems on RockAuto for less than $2.00 each. I also ordered hardened exhaust seats. This way I will have all the parts needed to do the valve job and will eliminate any head scratching at the machine shop.

I am considering doing the valve job and porting work backwards. Getting the guides and valve work completed first and then start porting, using clay or something to cover the valve seats. Not sure if anybody else has tried doing it that way.