Tubing the gallery with a twist

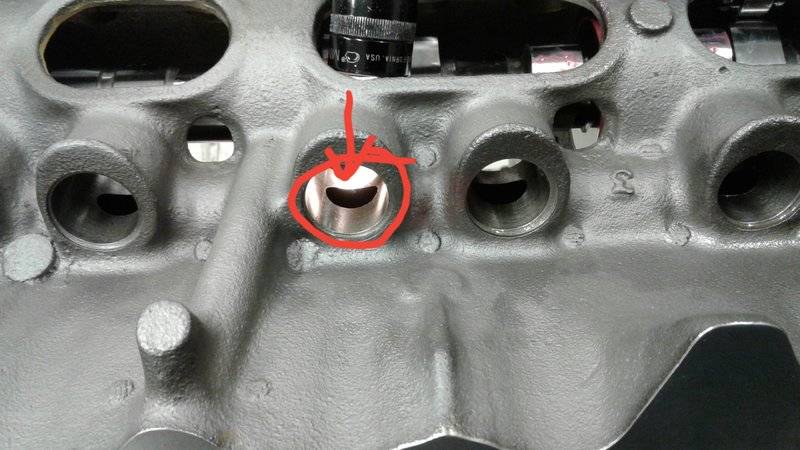

SO, after mocking up cam and lifters, it looks like I might have a "bleeder". The problem is NOT the top of the lifter bore. The problem is the oil hole in the bore itself. It's circled in pic 1. what happens is, at full lift the back skirted area of the lifter shown in pic 2 is exposed to the big hole and oil bleeds, sometimes squirts out the bottom of the bore. These are the much heralded MRL lifters. Outstanding product I have used several times. Most times they eliminate the problem, but not with this block.

what happens is, at full lift the back skirted area of the lifter shown in pic 2 is exposed to the big hole and oil bleeds, sometimes squirts out the bottom of the bore. These are the much heralded MRL lifters. Outstanding product I have used several times. Most times they eliminate the problem, but not with this block. I COULD have Bullet lower the base circle but with high spring pressures they don't think it's a good idea. I could also use Mikes lifters with a .750 roller instead of the .810. Not doing that either.

I COULD have Bullet lower the base circle but with high spring pressures they don't think it's a good idea. I could also use Mikes lifters with a .750 roller instead of the .810. Not doing that either.

Soooo I am going to tube both sides and somehow make sure that all the oiling stays as is. I still need oil to the rollers. THEN I will drill a small maybe 3/16 hole in every bore.....at a much better height.

Not sure if I will drill before I knock the tubes in and peen, or maybe when all done just use a small round carbide burr and then grind out a small hole.

I've never done this so any help, suggestions, etc is going to come HIGHLY appreciated.

Fingers crossed......

SO, after mocking up cam and lifters, it looks like I might have a "bleeder". The problem is NOT the top of the lifter bore. The problem is the oil hole in the bore itself. It's circled in pic 1.

Soooo I am going to tube both sides and somehow make sure that all the oiling stays as is. I still need oil to the rollers. THEN I will drill a small maybe 3/16 hole in every bore.....at a much better height.

Not sure if I will drill before I knock the tubes in and peen, or maybe when all done just use a small round carbide burr and then grind out a small hole.

I've never done this so any help, suggestions, etc is going to come HIGHLY appreciated.

Fingers crossed......