whitepunkonnitro

Well-Known Member

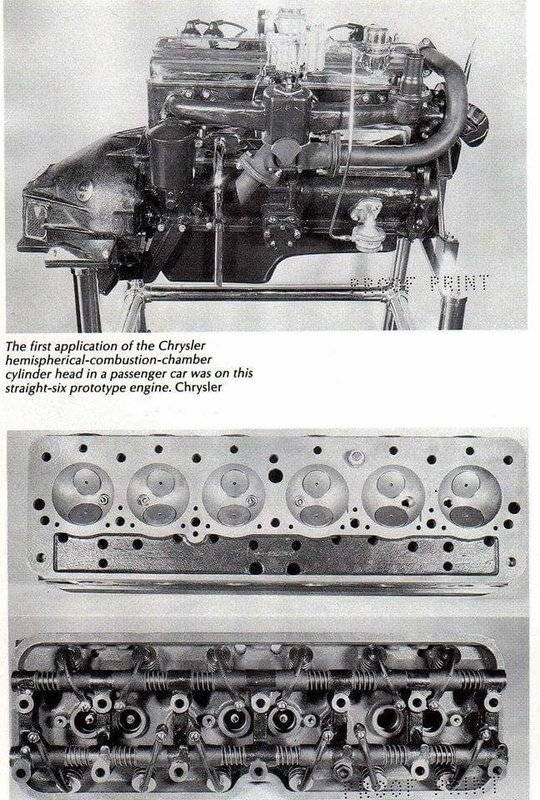

Take a look at this 1940's factory prototype inline 6 Hemi head.

I've never seen this before, but just eyeballing things up, it looks like it would be almost bolt on for a Slant.

Anybody have more info on this jewel?

I've never seen this before, but just eyeballing things up, it looks like it would be almost bolt on for a Slant.

Anybody have more info on this jewel?