Another Mopar Off My Bucket List - Barracuda Fastback

The new smaller battery will require the fabrication of a small battery box. Our plan is to attach it to the radiator wall close to where the factory location was.

One thing that I find disturbing is that the guys at Keith Black say we'll need a 4" exhaust. HOLY-CH-MOLY, - that's big! I'm wondering how hard it will be to fit that over the axle and alongside the fuel tank. Every time I look at the collectors they remind me of the difficulty we'll be facing later. My son is considering squashing the 4" exhaust into an oval shape to gain ground clearance. Another concern is if huge exhaust pipes would be really ugly sticking out the back. One possibility might be to split the two pipes into 4 separate exhaust tips.

Even though we already had a new power steering pump for the car my son opted to buy a billet aluminum replacement. Naturally, he also got the matching pulley.

Some of you may remember that the Charger did not have a radiator when Spencer bought it. When we were planning on the 512 build we purchased a new Champion aluminum 4-core. After doing some research my son decided to scrap the Champion and go with a 2-core 3 pass radiator instead. A lot of guys had said that the air flow through a 4-core was less and that the 3 pass radiators were more efficient. A few months back he ordered another radiator from Northern.

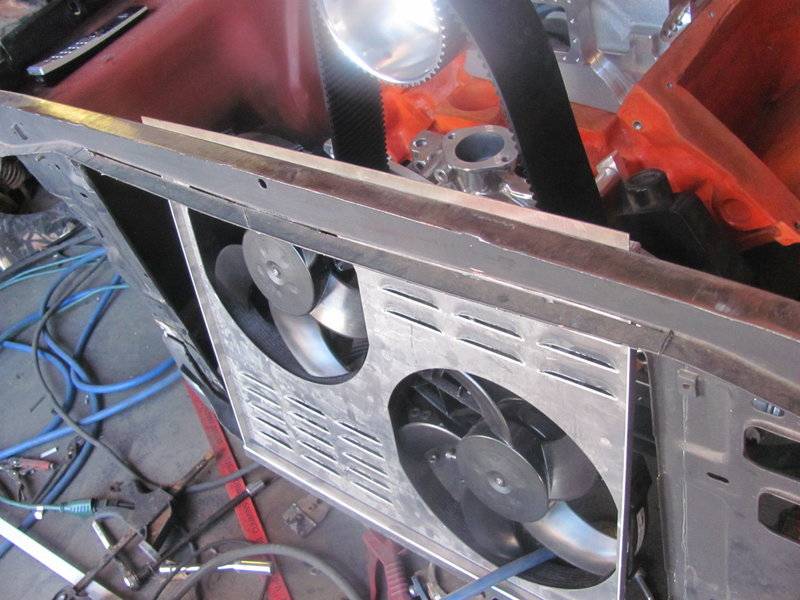

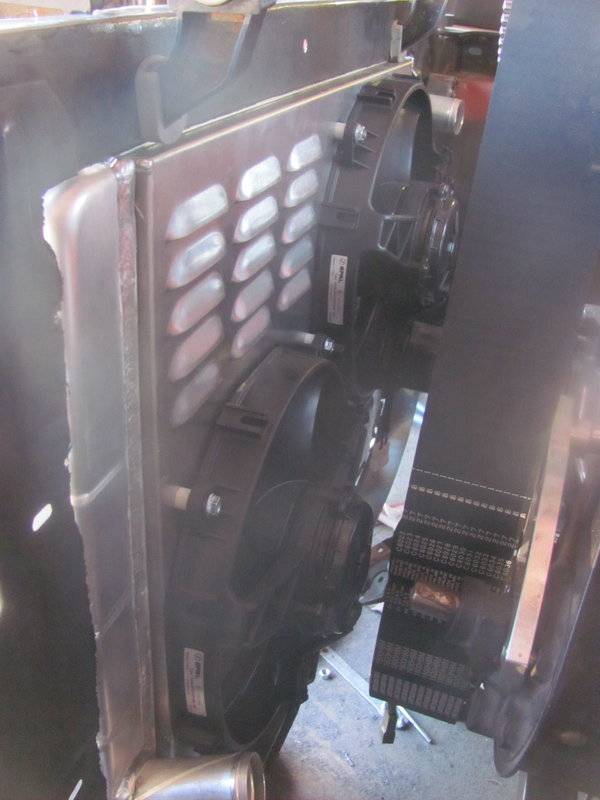

With the side tank design it was going to take some fab work to install it in the car. The combination fan/shrouds that they sold (designed for their radiators) were about 4" thick. The 3" blower belt drive didn't leave enough clearance. We were going to have to relocate the radiator farther forward. Before I had a chance to make any brackets for it he changed his mind again. He still liked the idea of running a 3 pass radiator but thought we might as well fit a wider one in the car if we were going to be modifying the radiator wall anyway. So-o-o-o, now we've got 3 new aluminum radiators for the car.

I guess a person shooting for 1200 HP in their daily driver has reason to be concerned about whether or not it's going to be boiling over at stop lights. Time will tell but according to his research we should have the best setup we could get.

Years ago when Spencer first decided he wanted to get a Charger, it was important to him that it be an actual R/T. He didn't want a clone. Well, this Charger is a true R/T. Despite all the modifications he'll be able to keep it badged as an R/T without having to say it's anything but. So when it comes to making modifications, he wants to keep all of the areas with factory stampings as intact as possible. The upper radiator support is one of those areas.

It took a lot of measuring to figure out the optimal size radiator. I knew we were going to have to do some cutting but felt we could retain that top support. The lower crossmember didn't matter. We had a beefier replacement for it. The wall itself was going to need several holes filled and Spence didn't mind me enlarging the opening for the larger radiator. Part of the dilemma was going to be that I needed to drop the lower support over an inch which would affect the hood latch support and the attaching points for the front valance panel.

I started by cutting the center bracket off of the lower crossmember after taking reference measurements.

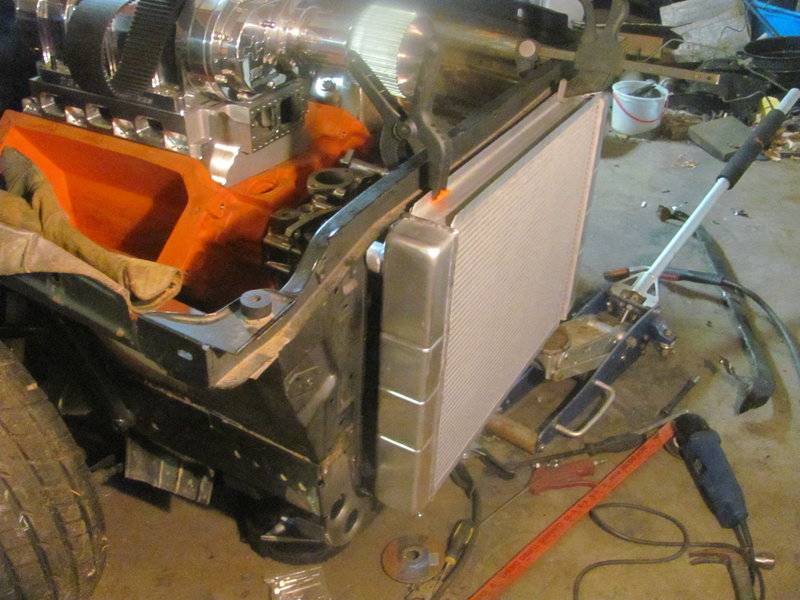

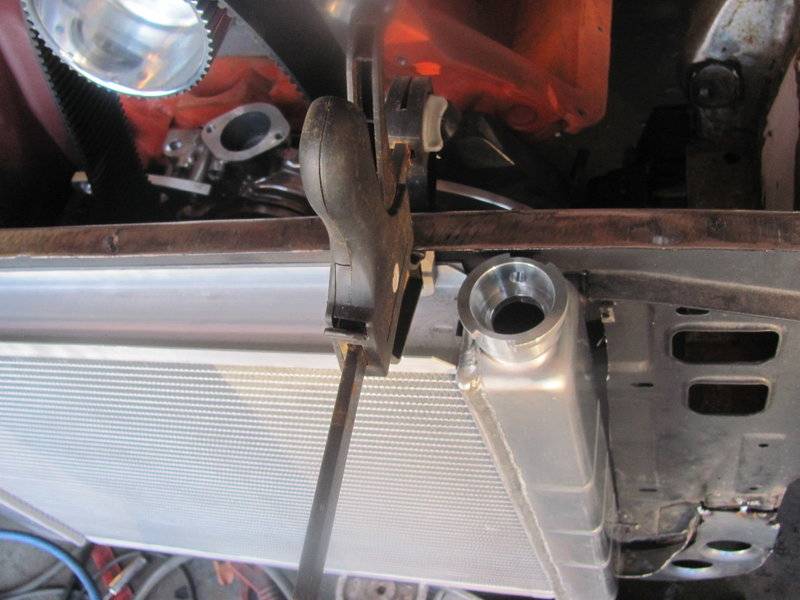

Once the center bracket was out of my way I began to fit the radiator into the opening.

From this point I could see wherever I needed to gain more clearance so the radiator could eventually be mounted flush. Next, I slid the bottom support crossmember over the original factory piece as a test fit.

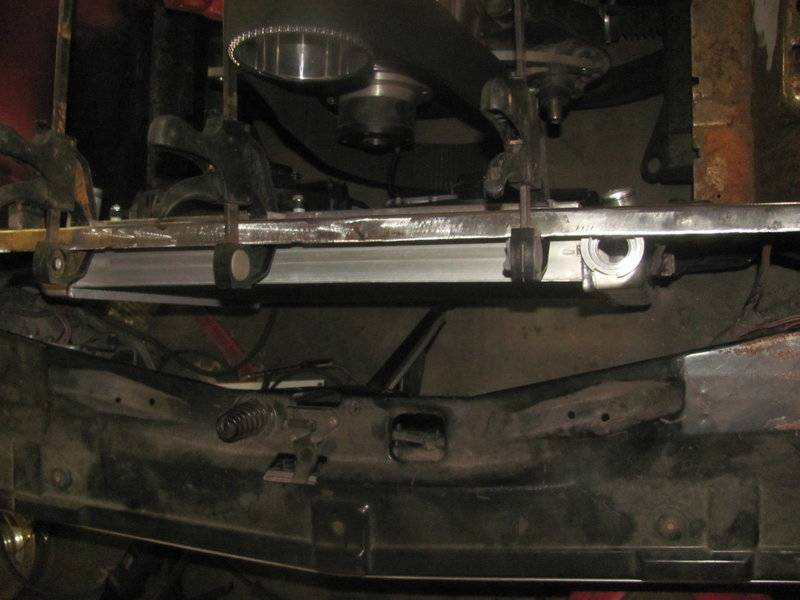

I still had to drop the lower support farther after testing the fitment. Once I was confident it would work I began chopping things up. The original lower support is a Z shape. The replacement is just an L shape. To make things work properly I needed to combine the two.

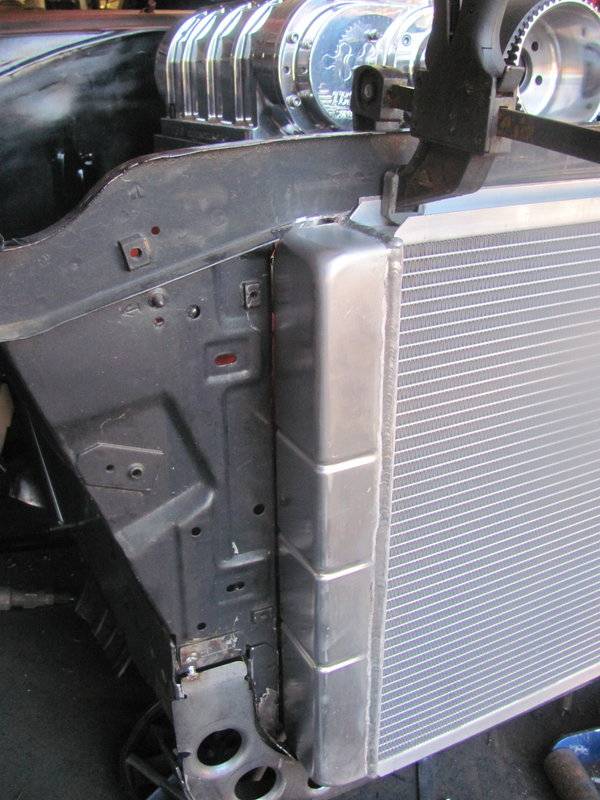

Once I had the height of the opening right it was time to start fitting the shroud and radiator again. As much as I didn't want to cut the upper support I was going to have to if I wanted the flush fit. I ended up notching it but left the factory stampings intact.

I still have to finish off the edges of the opening and am planning on a reinforcing lip that the radiator will slip into. Once everything is welded and ground down it should have a fairly factory look to it.

I went ahead and fit the fenders and grill assembly back on the car. So far it looks like everything is fitting pretty good.

The new smaller battery will require the fabrication of a small battery box. Our plan is to attach it to the radiator wall close to where the factory location was.

One thing that I find disturbing is that the guys at Keith Black say we'll need a 4" exhaust. HOLY-CH-MOLY, - that's big! I'm wondering how hard it will be to fit that over the axle and alongside the fuel tank. Every time I look at the collectors they remind me of the difficulty we'll be facing later. My son is considering squashing the 4" exhaust into an oval shape to gain ground clearance. Another concern is if huge exhaust pipes would be really ugly sticking out the back. One possibility might be to split the two pipes into 4 separate exhaust tips.

Even though we already had a new power steering pump for the car my son opted to buy a billet aluminum replacement. Naturally, he also got the matching pulley.

Some of you may remember that the Charger did not have a radiator when Spencer bought it. When we were planning on the 512 build we purchased a new Champion aluminum 4-core. After doing some research my son decided to scrap the Champion and go with a 2-core 3 pass radiator instead. A lot of guys had said that the air flow through a 4-core was less and that the 3 pass radiators were more efficient. A few months back he ordered another radiator from Northern.

With the side tank design it was going to take some fab work to install it in the car. The combination fan/shrouds that they sold (designed for their radiators) were about 4" thick. The 3" blower belt drive didn't leave enough clearance. We were going to have to relocate the radiator farther forward. Before I had a chance to make any brackets for it he changed his mind again. He still liked the idea of running a 3 pass radiator but thought we might as well fit a wider one in the car if we were going to be modifying the radiator wall anyway. So-o-o-o, now we've got 3 new aluminum radiators for the car.

I guess a person shooting for 1200 HP in their daily driver has reason to be concerned about whether or not it's going to be boiling over at stop lights. Time will tell but according to his research we should have the best setup we could get.

Years ago when Spencer first decided he wanted to get a Charger, it was important to him that it be an actual R/T. He didn't want a clone. Well, this Charger is a true R/T. Despite all the modifications he'll be able to keep it badged as an R/T without having to say it's anything but. So when it comes to making modifications, he wants to keep all of the areas with factory stampings as intact as possible. The upper radiator support is one of those areas.

It took a lot of measuring to figure out the optimal size radiator. I knew we were going to have to do some cutting but felt we could retain that top support. The lower crossmember didn't matter. We had a beefier replacement for it. The wall itself was going to need several holes filled and Spence didn't mind me enlarging the opening for the larger radiator. Part of the dilemma was going to be that I needed to drop the lower support over an inch which would affect the hood latch support and the attaching points for the front valance panel.

I started by cutting the center bracket off of the lower crossmember after taking reference measurements.

Once the center bracket was out of my way I began to fit the radiator into the opening.

From this point I could see wherever I needed to gain more clearance so the radiator could eventually be mounted flush. Next, I slid the bottom support crossmember over the original factory piece as a test fit.

I still had to drop the lower support farther after testing the fitment. Once I was confident it would work I began chopping things up. The original lower support is a Z shape. The replacement is just an L shape. To make things work properly I needed to combine the two.

Once I had the height of the opening right it was time to start fitting the shroud and radiator again. As much as I didn't want to cut the upper support I was going to have to if I wanted the flush fit. I ended up notching it but left the factory stampings intact.

I still have to finish off the edges of the opening and am planning on a reinforcing lip that the radiator will slip into. Once everything is welded and ground down it should have a fairly factory look to it.

I went ahead and fit the fenders and grill assembly back on the car. So far it looks like everything is fitting pretty good.