Need "Disc O Tech" article

Mopar Action On-line - Tech Archives Disc-o-Tech Article

Mopar Action On-line - Tech Archives PARTS LIST

Mopar Action On-line - Tech Archives RACE CALIPERS

Mopar Action On-line - Tech Archives HOSE JOB

Mopar Action On-line - Tech Archives Sources

DISC-O-TECH

Stop on a dime department

Awesome stopping power for virtually any Mopar with lowbuck stock parts - plus some racecar tricks!

Text and Photos

by Richard Ehrenberg

Everybody knows Mopars run like the proverbial scalded cat. Most Mopars even had decent stopping power, what with fat 11-inch drums or optional discs. However, as the pace of speed technology has hammered away at elapsed times, the braking scene, vis-a-vie our classic Mopes, has pretty much maintained the ol' status quo. For drag cars, there's always the option of the neat-o Wilwood kits, but they aren’t streetable. Anyway, for many of us, it's low buck or walk! What we’ve always needed is a way to upgrade our braking systems, be it from drums to discs, or, maybe even more importantly, from the now-rare (and expensive) 60s 4-piston disc setups to bigger, simpler late-'70s-based, single-piston stuff.

In the mid 1980s, this author wrote and published the definitive Mopar disc-swap article. In the interval since, we’ve published several updates and revisions, keeping pace with this supply-side reality: some parts are getting to be harder to find. So for this, a truly “master revision” (in computerese, this is V.2.0), we intend to instruct you on a swap to bring your Mopar's brakes up to snuff, using currently-available parts, with sourcing almost exclusively via boneyards, your local Chrysler dealer, and the corner auto-parts store. We'll totally avoid megabuck reproduction parts, one-off custom pieces, and expensive "race" parts. This conversion, or parts thereof, will work on virtually every Mopar built from 1962 through 1989, whether originally equipped with standard drums, HD drums, or discs, and now we’ve even got help for those kiloton C-body bruisers. The main thrust of this information will be concentrated on those cars that need the help the most: '62-'72 B-Bodies (including Road Runners, Chargers, GTXs, Satellites, etc.) and the much- loved E-body ponycars (Challengers and ‘70-up 'Cudas.) These cars all use a virtually identical front suspension layout, the only real differences being the swaybar design (which varies somewhat from year to year) and, of course, the brakes. Then, we'll detail some specific information for the "rest" of the Mopar tribes out there, including later cars and A and C-bodies. This will be a totally bolt-on deal, requiring absolutely no fabrication, cutting, or welding. Proper OEM suspension geometry and hose routing will not be compromised. And then we’ll go “one step beyond”, detailing a swap for track vehicle owners who would like the big, cheap Mopar rotors and the advantages of lightweight aluminum 4-piston calipers. Other than a typical "Sears, Roebuck" set of hand tools, the only item that would be useful to have handy would be a '70-'72 factory service manual.

STARTING POINT

Mopars of our "prime target" group came factory-equipped with one of two different possibilities for drums (10" and 11") and two possible disc setups (Bendix 4-piston on the '66-'69 cars, and single-piston Kelsey-Hayes pin-type on the '70-'72s) All the disc-brake-equipped cars of this era used two-piece rotor/hub assemblies (see fig. 1) Besides being expensive to replace (even the current repros aren’t cheap), these were a major hindrance to achieving truly high performance braking. If the rotors got hot enough, by either very exuberant braking or by installing metal compound lining material, the rotors would warp, resulting in a very unnerving, pulsating brake pedal. The rotors would usually return to a semblance of straightness when they cooled, but this setup obviously left something to be desired. Later B-bodies used a "unicast" (one-piece cast iron) hub/rotor assembly, solving the warpage problem, but opening another can of worms, namely, hub, strength. A sudden impact, or years of vibration and road shock have been known to cause hub failure, something you don't want to experience. Yeah, watching your wheel/tire/hub combo bouncing aimlessly over a freeway median at 75, as you scrape to a sudden, sparky, halt is not high on our list of fun ways to spend the weekend. The factory finally got their act together in 1976 with the introduction of the 11.75" unicast police rotors with cast-in reinforcing ribs (see fig. 2). It's these rotors that we're going to install on our subject car, a '71 383 'Cuda. We’ll deal with the actual how-to-do-it part of this swap with a set of detailed captioned photographs, which will walk you through the entire procedure, step-by-step.

Click On Pictures To Load Full Size

Here's everything you'll need to get the job done. Redundant parts, which are used in duplicate on the opposite side of the car, are not shown.

Numbers are keyed to the parts list.

PARTS PROCUREMENT and OPTIONS

On all Mopars, the swap from drums to discs (or 2-piece rotors to unicast rotors) requires one "key" part: A new steering knuckle (a/k/a "spindle.") The knuckle you need for our primary swap is from any '73-'74 E-body, or, believe it or not, any '73- '76 disc-equipped A-body (Valiant/Dart/Duster). This is a non- wearing part and perfect examples can be had at most junkyards (see phto below), but if you run into trouble, excellent repros are now available from Master Power Brakes, Inc. Do not succumb to the temptation to use "lookalike" knuckles from later Mopars, such as 73-up B/R-bodies, F/J/M bodies, etc. These parts, while visually very similar, are taller, altering suspension geometry (camber change, bump steer, etc.), and possibly forcing the ball joints beyond their designed range, a/k/a “over angling”. Also do not swap the knuckles side-to-side to mount the caliper toward the rear, this causes brake hose routing difficulties. While the correct mounting avoids these problems, on some cars you may encounter swaybar-to-caliper interference. We suggest dealing with that via other methods, described later. Using the correct knuckle avoids any of these potential pitfalls, and results in a "factory engineered" installation. Hey, Chrysler paid those engineers big bucks to get it right, so you might as well take advantage of their knowhow. Plus, we're getting it for free!

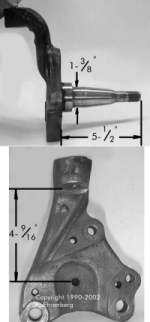

This will help you identify the needed ‘74-‘74 E-body / ‘73- ‘76 A-body steering knuckle. Casting numbers are rarely visible, so comparing dimensions is the sure way. Be sure to inspect for spun-bearing damage. Exact, drop-forged steel repros are available from Master Power (see sources.) Do not use the similar, but taller, knuckles from ‘73-up B and F/J/M/R-body cars!

You'll also need a pair of rotors and caliper adapters (a.k.a. brackets) from most any '76-'79 B-body or 79-up R-body (St. Regis, etc.) Be careful when perusing the boneyards for theses, as Mother Mopar pulled off quite a bit of "badge engineering" in this period, resulting in some B-bodies carrying traditional C- body nameplates. The sure cure: check the VIN tag. Find an R, W, X, or S as the first character, and you're home free. Note also that many 2-door B-bodies (X, S) of that generation, as well as the R-bodies, used the "slider" type calipers, which we don’t like as well as the K-H pin type (they require more maintenance), but if that’s all you can find, go for it, and repros of them are also now being sold by Master Power. (It has also become very difficult to find new ‘pins’ (bolts) for the pin-type calipers.) You'll also need a pair of rebuilt calipers and the correct hoses (see parts list), which you can usually find inexpensively at a local parts house. (Should you decide to go with the slider calipers, use hoses from a ‘73-‘76 A-body).

On the left are two of the desired unicast rotors. The reinforcing ribs are clearly visible - make sure the ones you use have ‘em! On the right is one of the early two-piece rotors. The pencil is pointing to the hub/rotor junction point.

#4 and #5 are our two K-H pin-type calipers, left and right sides. The unnumbered caliper on the right is a later B-body slider. Note difference in hose fitting location. Don’t use this design on the “target” group of cars (see text).

Additionally, besides the obvious parts such as pads, wheel bearings and seals, splash shields, etc., you'll need, (only) if you now have drums, a master cylinder from virtually any '70-up disc car, even one from such common junkyard dogs as a 1976-78 F-body (Volaré/Aspen.) Later cars ('79-up) used a neat, lightweight aluminum master cylinder, but it was attached to the firewall (or vacuum booster) via only two bolts, as opposed to the earlier 4-bolt arrangement, requiring an adapter plate (Mopar Performance P5249305 or AR Engineering MC1002) to install. Alternately, you may be able to adapt a later 2-stud booster. Next, you'll need a rear brake proportioning valve. The valve may be of the stock non-adjustable variety (which, in some years, was built into the brake tee assembly.) Ideally, though, for ease of installation and, more importantly, optimization of front/rear braking balance, the Mopar Performance/Wilwood "add-on" adjustable valve, Mopar #P5249088 (or similar) is highly recommended, and, therefore, was used in our swap. The standard, nonadjustable valve was, of necessity, a compromise. The same valve was used on wagons and 2-door coupes, slant sixes and Hemicars, meaning that most cars rolled out of the assembly plant with less-than-ideal proportioning, characterized by a tendency toward early rear-wheel lockup.

There are other ways to alter front/rear balance. One way, which reduces rear lockup, is to use a 7/8-inch rear wheel cylinder in place of the standard 15/16-inch unit. Try Raybestos part number WC37236 for this. (Original application: late ‘70-early ‘80s light-duty Dodge trucks w/10-in. rear drums).

The second variable is caliper piston size. The slider-type calipers used on 1973-‘75 A-bodies used a smaller piston: 2.60" as opposed to the more common 2.75". Using these can be helpful if your car has a “reverse” proportioning problem and tends to lock the fronts first, usually only a problem with no-option, slant-six cars or lightened drag cars.

The caliper adapters for the 11.75" rotors measures 3.5" (dim. “A”) from the center of the "pin" holes to the center of the mounting holes. The optional adapter (for 14" wheels/10.87" rotors) measures 3.125" C-C (Dim “B”).

The caliper adapters for the 11.75" rotors measures 3.5" (dim. “A”) from the center of the "pin" holes to the center of the mounting holes. The optional adapter (for 14" wheels/10.87" rotors) measures 3.125" C-C (Dim “B”).

Slider adapter are also made for each of the two rotor sizes. Measure from the center of the mounting hole to a flat surface. If it’s 3-1/4", it fits the small rotors, 3-5/8" fit the biggies.

Slider calipers were produced in “standard” and “H.D.” versions. Note ribbing and extra iron on the H.D. baby on the left. These two adapters are 100% interchangeable

Slider calipers were produced in “standard” and “H.D.” versions. Note ribbing and extra iron on the H.D. baby on the left. These two adapters are 100% interchangeable

Some factory installations, notably C-body and later B-body cars, used a “combination” valve, which also included a front-brake metering valve. Its function was a allow the rear brakes to achieve some minimal line pressure (against the return springs) before the fronts began to apply. This was supposed to reduce the possibility of the fronts locking up first on glare ice. Don’t worry about this, besides, with the rears locked first, the car must spin. In addition, none of these valves are no longer available new, repops are from who-knows-where, and most available junkyard samples all seem to be made of cast iron (instead of brass) so they’re rust city. Again, your best bet is to just leave your stock “tee / switch” assembly unmolested and plumb in an adjustable valve in the rear line, as we’ve done in our swap.

As we mentioned, you will encounter swaybar-to-caliper interference if you install this setup on a pre-1970 B-body equipped with the link-type swaybar. Your alternatives here are an aftermarket swaybar setup (Addco, etc.) or to convert to the '70-'72 setup. This swap requires either using lower control arm/swaybar bracket assemblies from the '70-'72s, or torching the brackets off your original arms and rewelding them in the '70-'72 location (you'll still need the '70-'72 bar itself). In some cases, pre-'70 cars may not have the clearance notch required for the '70-up style bar, which passes through the K-member. To cure this, either swap to a '70-up K-member, use an aftermarket bar, or rework the K-member.

Don't worry if it looks like a lot of parts. Many of the components can be had at least partially preassembled. The parts are garden variety and usually quite inexpensive. For example, we paid ten bucks for a pair of the caliper adapters at local auto wrecking yard. The knuckles were obtained gratis from a neighbor who was junking a '75 Valiant. Our local auto parts store once had the rotors on sale for $39.95, brand new! A shrewd shopper should be able to pull off the whole shebang for $300 - 400 and have enough left for a large pepperoni pizza. And, if you hate shopping for lots of small parts, Master Power Brakes, Inc. now offers a complete clone of this setup (small rotors only) ready to bolt on.

OUT BACK

Whether or not you your car was originally disc-equipped, it may have either 10 or 11-inch rear drums. Either setup seems to do just fine. (Just be sure they're in good shape). The front brakes do 60 to 70% of the braking anyway, and with your humongous new 11.75" rotors and semimetallic pads up front, you'll have no shortage of stopping power.

Much has been written about rear discs. Everybody lusts after the early-‘70s Imperial units. In a word, don’t! Chrysler engineers have told me, point blank, that the only reason they went to 4- wheel discs on any car (possibly excluding the Viper) was “competitive pressure”. They feel there’s little performance gain. Then there’s the fact that the Imp parts are now scare as hen’s teeth, and require custom-length axles to install on 8.75" axles (unless you want to give up your beefy Timken rear wheel bearings for rinky-dink ball-type bearings.)

Let the games begin! Step one, after safely supporting the vehicle on stands, is to soak the hose fitting with rust penetrant. Then unscrew the hose fitting and remove the retaining clip

Let the games begin! Step one, after safely supporting the vehicle on stands, is to soak the hose fitting with rust penetrant. Then unscrew the hose fitting and remove the retaining clip

Now remove the drum in the usual manner. Save, and recycle, the outer wheel bearing, thrust washer, nut, and the nut lock. Unbolt the knuckle from the backing plate and ball joint, as shown. The separate the upper ball stud from the knuckle by using either the factory puller or a pickle fork. If you use the fork, you'll probably ruin the upper seal, which must be replaced.

Pull the old stuff off the car, and the teardown is complete. Of course, if you plan on doing any additional front-end work, now's the time!

Pull the old stuff off the car, and the teardown is complete. Of course, if you plan on doing any additional front-end work, now's the time!

New knuckle bolts in place exactly the same way as the old one came off. Re-use the old ball joint bolts, with thread locking compound, torqued to 120 ft./lbs. Then bolt the adapters in place, and torque to 95 ft./lbs, as we're doing here. Use only the bolts shown in the parts list for this application - no substitutes!

Here is the archived copy of the Disc-o-Tech article. Copy directly from these archived web links, or from the article contained in these 3 posts.

Mopar Action On-line - Tech Archives Disc-o-Tech Article

Mopar Action On-line - Tech Archives PARTS LIST

Mopar Action On-line - Tech Archives RACE CALIPERS

Mopar Action On-line - Tech Archives HOSE JOB

Mopar Action On-line - Tech Archives Sources

DISC-O-TECH

Stop on a dime department

Awesome stopping power for virtually any Mopar with lowbuck stock parts - plus some racecar tricks!

Text and Photos

by Richard Ehrenberg

Everybody knows Mopars run like the proverbial scalded cat. Most Mopars even had decent stopping power, what with fat 11-inch drums or optional discs. However, as the pace of speed technology has hammered away at elapsed times, the braking scene, vis-a-vie our classic Mopes, has pretty much maintained the ol' status quo. For drag cars, there's always the option of the neat-o Wilwood kits, but they aren’t streetable. Anyway, for many of us, it's low buck or walk! What we’ve always needed is a way to upgrade our braking systems, be it from drums to discs, or, maybe even more importantly, from the now-rare (and expensive) 60s 4-piston disc setups to bigger, simpler late-'70s-based, single-piston stuff.

In the mid 1980s, this author wrote and published the definitive Mopar disc-swap article. In the interval since, we’ve published several updates and revisions, keeping pace with this supply-side reality: some parts are getting to be harder to find. So for this, a truly “master revision” (in computerese, this is V.2.0), we intend to instruct you on a swap to bring your Mopar's brakes up to snuff, using currently-available parts, with sourcing almost exclusively via boneyards, your local Chrysler dealer, and the corner auto-parts store. We'll totally avoid megabuck reproduction parts, one-off custom pieces, and expensive "race" parts. This conversion, or parts thereof, will work on virtually every Mopar built from 1962 through 1989, whether originally equipped with standard drums, HD drums, or discs, and now we’ve even got help for those kiloton C-body bruisers. The main thrust of this information will be concentrated on those cars that need the help the most: '62-'72 B-Bodies (including Road Runners, Chargers, GTXs, Satellites, etc.) and the much- loved E-body ponycars (Challengers and ‘70-up 'Cudas.) These cars all use a virtually identical front suspension layout, the only real differences being the swaybar design (which varies somewhat from year to year) and, of course, the brakes. Then, we'll detail some specific information for the "rest" of the Mopar tribes out there, including later cars and A and C-bodies. This will be a totally bolt-on deal, requiring absolutely no fabrication, cutting, or welding. Proper OEM suspension geometry and hose routing will not be compromised. And then we’ll go “one step beyond”, detailing a swap for track vehicle owners who would like the big, cheap Mopar rotors and the advantages of lightweight aluminum 4-piston calipers. Other than a typical "Sears, Roebuck" set of hand tools, the only item that would be useful to have handy would be a '70-'72 factory service manual.

STARTING POINT

Mopars of our "prime target" group came factory-equipped with one of two different possibilities for drums (10" and 11") and two possible disc setups (Bendix 4-piston on the '66-'69 cars, and single-piston Kelsey-Hayes pin-type on the '70-'72s) All the disc-brake-equipped cars of this era used two-piece rotor/hub assemblies (see fig. 1) Besides being expensive to replace (even the current repros aren’t cheap), these were a major hindrance to achieving truly high performance braking. If the rotors got hot enough, by either very exuberant braking or by installing metal compound lining material, the rotors would warp, resulting in a very unnerving, pulsating brake pedal. The rotors would usually return to a semblance of straightness when they cooled, but this setup obviously left something to be desired. Later B-bodies used a "unicast" (one-piece cast iron) hub/rotor assembly, solving the warpage problem, but opening another can of worms, namely, hub, strength. A sudden impact, or years of vibration and road shock have been known to cause hub failure, something you don't want to experience. Yeah, watching your wheel/tire/hub combo bouncing aimlessly over a freeway median at 75, as you scrape to a sudden, sparky, halt is not high on our list of fun ways to spend the weekend. The factory finally got their act together in 1976 with the introduction of the 11.75" unicast police rotors with cast-in reinforcing ribs (see fig. 2). It's these rotors that we're going to install on our subject car, a '71 383 'Cuda. We’ll deal with the actual how-to-do-it part of this swap with a set of detailed captioned photographs, which will walk you through the entire procedure, step-by-step.

Click On Pictures To Load Full Size

Here's everything you'll need to get the job done. Redundant parts, which are used in duplicate on the opposite side of the car, are not shown.

Numbers are keyed to the parts list.

PARTS PROCUREMENT and OPTIONS

On all Mopars, the swap from drums to discs (or 2-piece rotors to unicast rotors) requires one "key" part: A new steering knuckle (a/k/a "spindle.") The knuckle you need for our primary swap is from any '73-'74 E-body, or, believe it or not, any '73- '76 disc-equipped A-body (Valiant/Dart/Duster). This is a non- wearing part and perfect examples can be had at most junkyards (see phto below), but if you run into trouble, excellent repros are now available from Master Power Brakes, Inc. Do not succumb to the temptation to use "lookalike" knuckles from later Mopars, such as 73-up B/R-bodies, F/J/M bodies, etc. These parts, while visually very similar, are taller, altering suspension geometry (camber change, bump steer, etc.), and possibly forcing the ball joints beyond their designed range, a/k/a “over angling”. Also do not swap the knuckles side-to-side to mount the caliper toward the rear, this causes brake hose routing difficulties. While the correct mounting avoids these problems, on some cars you may encounter swaybar-to-caliper interference. We suggest dealing with that via other methods, described later. Using the correct knuckle avoids any of these potential pitfalls, and results in a "factory engineered" installation. Hey, Chrysler paid those engineers big bucks to get it right, so you might as well take advantage of their knowhow. Plus, we're getting it for free!

This will help you identify the needed ‘74-‘74 E-body / ‘73- ‘76 A-body steering knuckle. Casting numbers are rarely visible, so comparing dimensions is the sure way. Be sure to inspect for spun-bearing damage. Exact, drop-forged steel repros are available from Master Power (see sources.) Do not use the similar, but taller, knuckles from ‘73-up B and F/J/M/R-body cars!

You'll also need a pair of rotors and caliper adapters (a.k.a. brackets) from most any '76-'79 B-body or 79-up R-body (St. Regis, etc.) Be careful when perusing the boneyards for theses, as Mother Mopar pulled off quite a bit of "badge engineering" in this period, resulting in some B-bodies carrying traditional C- body nameplates. The sure cure: check the VIN tag. Find an R, W, X, or S as the first character, and you're home free. Note also that many 2-door B-bodies (X, S) of that generation, as well as the R-bodies, used the "slider" type calipers, which we don’t like as well as the K-H pin type (they require more maintenance), but if that’s all you can find, go for it, and repros of them are also now being sold by Master Power. (It has also become very difficult to find new ‘pins’ (bolts) for the pin-type calipers.) You'll also need a pair of rebuilt calipers and the correct hoses (see parts list), which you can usually find inexpensively at a local parts house. (Should you decide to go with the slider calipers, use hoses from a ‘73-‘76 A-body).

On the left are two of the desired unicast rotors. The reinforcing ribs are clearly visible - make sure the ones you use have ‘em! On the right is one of the early two-piece rotors. The pencil is pointing to the hub/rotor junction point.

#4 and #5 are our two K-H pin-type calipers, left and right sides. The unnumbered caliper on the right is a later B-body slider. Note difference in hose fitting location. Don’t use this design on the “target” group of cars (see text).

Additionally, besides the obvious parts such as pads, wheel bearings and seals, splash shields, etc., you'll need, (only) if you now have drums, a master cylinder from virtually any '70-up disc car, even one from such common junkyard dogs as a 1976-78 F-body (Volaré/Aspen.) Later cars ('79-up) used a neat, lightweight aluminum master cylinder, but it was attached to the firewall (or vacuum booster) via only two bolts, as opposed to the earlier 4-bolt arrangement, requiring an adapter plate (Mopar Performance P5249305 or AR Engineering MC1002) to install. Alternately, you may be able to adapt a later 2-stud booster. Next, you'll need a rear brake proportioning valve. The valve may be of the stock non-adjustable variety (which, in some years, was built into the brake tee assembly.) Ideally, though, for ease of installation and, more importantly, optimization of front/rear braking balance, the Mopar Performance/Wilwood "add-on" adjustable valve, Mopar #P5249088 (or similar) is highly recommended, and, therefore, was used in our swap. The standard, nonadjustable valve was, of necessity, a compromise. The same valve was used on wagons and 2-door coupes, slant sixes and Hemicars, meaning that most cars rolled out of the assembly plant with less-than-ideal proportioning, characterized by a tendency toward early rear-wheel lockup.

There are other ways to alter front/rear balance. One way, which reduces rear lockup, is to use a 7/8-inch rear wheel cylinder in place of the standard 15/16-inch unit. Try Raybestos part number WC37236 for this. (Original application: late ‘70-early ‘80s light-duty Dodge trucks w/10-in. rear drums).

The second variable is caliper piston size. The slider-type calipers used on 1973-‘75 A-bodies used a smaller piston: 2.60" as opposed to the more common 2.75". Using these can be helpful if your car has a “reverse” proportioning problem and tends to lock the fronts first, usually only a problem with no-option, slant-six cars or lightened drag cars.

Slider adapter are also made for each of the two rotor sizes. Measure from the center of the mounting hole to a flat surface. If it’s 3-1/4", it fits the small rotors, 3-5/8" fit the biggies.

Some factory installations, notably C-body and later B-body cars, used a “combination” valve, which also included a front-brake metering valve. Its function was a allow the rear brakes to achieve some minimal line pressure (against the return springs) before the fronts began to apply. This was supposed to reduce the possibility of the fronts locking up first on glare ice. Don’t worry about this, besides, with the rears locked first, the car must spin. In addition, none of these valves are no longer available new, repops are from who-knows-where, and most available junkyard samples all seem to be made of cast iron (instead of brass) so they’re rust city. Again, your best bet is to just leave your stock “tee / switch” assembly unmolested and plumb in an adjustable valve in the rear line, as we’ve done in our swap.

As we mentioned, you will encounter swaybar-to-caliper interference if you install this setup on a pre-1970 B-body equipped with the link-type swaybar. Your alternatives here are an aftermarket swaybar setup (Addco, etc.) or to convert to the '70-'72 setup. This swap requires either using lower control arm/swaybar bracket assemblies from the '70-'72s, or torching the brackets off your original arms and rewelding them in the '70-'72 location (you'll still need the '70-'72 bar itself). In some cases, pre-'70 cars may not have the clearance notch required for the '70-up style bar, which passes through the K-member. To cure this, either swap to a '70-up K-member, use an aftermarket bar, or rework the K-member.

Don't worry if it looks like a lot of parts. Many of the components can be had at least partially preassembled. The parts are garden variety and usually quite inexpensive. For example, we paid ten bucks for a pair of the caliper adapters at local auto wrecking yard. The knuckles were obtained gratis from a neighbor who was junking a '75 Valiant. Our local auto parts store once had the rotors on sale for $39.95, brand new! A shrewd shopper should be able to pull off the whole shebang for $300 - 400 and have enough left for a large pepperoni pizza. And, if you hate shopping for lots of small parts, Master Power Brakes, Inc. now offers a complete clone of this setup (small rotors only) ready to bolt on.

OUT BACK

Whether or not you your car was originally disc-equipped, it may have either 10 or 11-inch rear drums. Either setup seems to do just fine. (Just be sure they're in good shape). The front brakes do 60 to 70% of the braking anyway, and with your humongous new 11.75" rotors and semimetallic pads up front, you'll have no shortage of stopping power.

Much has been written about rear discs. Everybody lusts after the early-‘70s Imperial units. In a word, don’t! Chrysler engineers have told me, point blank, that the only reason they went to 4- wheel discs on any car (possibly excluding the Viper) was “competitive pressure”. They feel there’s little performance gain. Then there’s the fact that the Imp parts are now scare as hen’s teeth, and require custom-length axles to install on 8.75" axles (unless you want to give up your beefy Timken rear wheel bearings for rinky-dink ball-type bearings.)

Now remove the drum in the usual manner. Save, and recycle, the outer wheel bearing, thrust washer, nut, and the nut lock. Unbolt the knuckle from the backing plate and ball joint, as shown. The separate the upper ball stud from the knuckle by using either the factory puller or a pickle fork. If you use the fork, you'll probably ruin the upper seal, which must be replaced.

New knuckle bolts in place exactly the same way as the old one came off. Re-use the old ball joint bolts, with thread locking compound, torqued to 120 ft./lbs. Then bolt the adapters in place, and torque to 95 ft./lbs, as we're doing here. Use only the bolts shown in the parts list for this application - no substitutes!