Need "Disc O Tech" article

Install the new splash shields, using the foam gaskets (item #12 in the parts chart) and ordinary dime-store 5/16-18 X 3/4" screws. if you can't find shield, don't fret. Experience -- and a look at a modern car -- shows that they are really just eye candy.

Install the new splash shields, using the foam gaskets (item #12 in the parts chart) and ordinary dime-store 5/16-18 X 3/4" screws. if you can't find shield, don't fret. Experience -- and a look at a modern car -- shows that they are really just eye candy.

Pack the wheel bearings in the usual way, and install the seal. Mopar hi-temp lube (p/n 4318064) is the ticket!

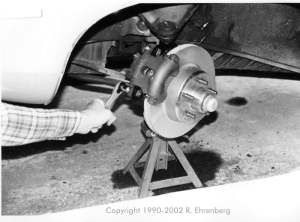

Real, visible progress! We've installed the rotors, adjusted the bearings, and installed the dust new dust cap. With discs, there must be zero end play. Tighten until the play just disappears, then a skosh more. If you chintzed out and used Chinese aftermarket grease caps, spin the rotor a few times, then pop the cap off (look for witness marks) to be sure that the cotter pin isn't scraping the inside of the cap -- filling your bearings with metal chips! A real tight wrap of the cotter, and an undented cap, is necessary to prevent this.

Real, visible progress! We've installed the rotors, adjusted the bearings, and installed the dust new dust cap. With discs, there must be zero end play. Tighten until the play just disappears, then a skosh more. If you chintzed out and used Chinese aftermarket grease caps, spin the rotor a few times, then pop the cap off (look for witness marks) to be sure that the cotter pin isn't scraping the inside of the cap -- filling your bearings with metal chips! A real tight wrap of the cotter, and an undented cap, is necessary to prevent this.

Screw the flex hoses onto the calipers before installation. Don't forget the copper washer (pencil.) If your calipers came without the rubber bushings in place, install them now. Slider calipers require two copper washers, and the banjo bolt (p/n 6030026).

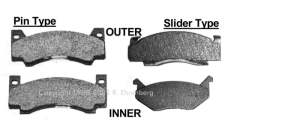

Pay careful attention to the subtle difference between the inner and outer pads. Outer pads also typically have thicker lining. After what seems like an eternity, we can now get super, molded, metallic-carbon pads from Firm Feel, Inc. (See sources)

Pay careful attention to the subtle difference between the inner and outer pads. Outer pads also typically have thicker lining. After what seems like an eternity, we can now get super, molded, metallic-carbon pads from Firm Feel, Inc. (See sources)

Before installing the caliper, drop the inner pad in to place between the adapter and the rotor- it's just barely visible in this photo. Now, slip the outer pad inside the caliper's outer flange. Holding the outer (pin type) pad in place by hand, slip the caliper into position.

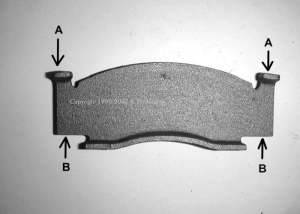

Sliders need to have the outer pad custom-fitted to the caliper. Hammer the tabs (A) while supporting the bottom edge (B) on an anvil, brick, etc. The pad should just barely “snap” into place on the caliper. Too loose? Won’t fit? Bend again!

Sliders need to have the outer pad custom-fitted to the caliper. Hammer the tabs (A) while supporting the bottom edge (B) on an anvil, brick, etc. The pad should just barely “snap” into place on the caliper. Too loose? Won’t fit? Bend again!

Install the guide pins, and torque 'em to 35 ft./lbs. Note that some jiggling may be required to line everything up. If you find any anti-rattle springs, clips, etc., packed with your calipers or pads, just toss 'em over your shoulder! If you are using the slider-type calipers, there are no bushings or pins, just the retainers and small screws. With the slider setup, be sure the “ways” are smooth and lubed with silicone grease.

Slip the flex hose into the frame bracket, and reinstall the clip. Tighten the original steel line (arrow) into the new hose, Congrats! You've finished one side. Look at all the pictures in a mirror to complete the passenger's side! Bleed both calipers using your favorite method: gravity, pumping, or pressure. Be sure you have a firm pedal before moving the car. A quick trip to the alignment rack, and it's a done deal! (Remember, a little negative camber goes a long way towards improving cornering grip).

Slip the flex hose into the frame bracket, and reinstall the clip. Tighten the original steel line (arrow) into the new hose, Congrats! You've finished one side. Look at all the pictures in a mirror to complete the passenger's side! Bleed both calipers using your favorite method: gravity, pumping, or pressure. Be sure you have a firm pedal before moving the car. A quick trip to the alignment rack, and it's a done deal! (Remember, a little negative camber goes a long way towards improving cornering grip).

Here's the completed installation in the slider-caliper version. Note that in all cases the calipers are on the front - this maintains factory specifications for hose routing, saving your butt. Resist the temptation to reverse them, unless you are REALLY REALLY sure you've got the hose routing 'covered' at the limits of steering and suspension travel, no abrasion, etc.

Here’s the fat rotor, 15-in wheel setup from the rear. As you can see, no way are 14-in. wheels gonna clear this setup.

Here’s the fat rotor, 15-in wheel setup from the rear. As you can see, no way are 14-in. wheels gonna clear this setup.

For proportioning valve installation, hack through the brake line and armor at a point approximately 17" forward of the torsion bar crossmember. It's not critical.

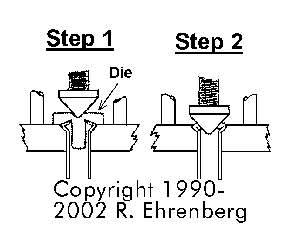

Unwind and discard about one inch of armor from each of the cut ends, and double flare the tubing, using a tool such as this. The ends must look like the drawing when you’re done. And - remember to slide the tubing nuts on before you flare the ends!

Pack the wheel bearings in the usual way, and install the seal. Mopar hi-temp lube (p/n 4318064) is the ticket!

Screw the flex hoses onto the calipers before installation. Don't forget the copper washer (pencil.) If your calipers came without the rubber bushings in place, install them now. Slider calipers require two copper washers, and the banjo bolt (p/n 6030026).

Before installing the caliper, drop the inner pad in to place between the adapter and the rotor- it's just barely visible in this photo. Now, slip the outer pad inside the caliper's outer flange. Holding the outer (pin type) pad in place by hand, slip the caliper into position.

Install the guide pins, and torque 'em to 35 ft./lbs. Note that some jiggling may be required to line everything up. If you find any anti-rattle springs, clips, etc., packed with your calipers or pads, just toss 'em over your shoulder! If you are using the slider-type calipers, there are no bushings or pins, just the retainers and small screws. With the slider setup, be sure the “ways” are smooth and lubed with silicone grease.

Here's the completed installation in the slider-caliper version. Note that in all cases the calipers are on the front - this maintains factory specifications for hose routing, saving your butt. Resist the temptation to reverse them, unless you are REALLY REALLY sure you've got the hose routing 'covered' at the limits of steering and suspension travel, no abrasion, etc.

For proportioning valve installation, hack through the brake line and armor at a point approximately 17" forward of the torsion bar crossmember. It's not critical.

Unwind and discard about one inch of armor from each of the cut ends, and double flare the tubing, using a tool such as this. The ends must look like the drawing when you’re done. And - remember to slide the tubing nuts on before you flare the ends!