273 rocker arm adjustment

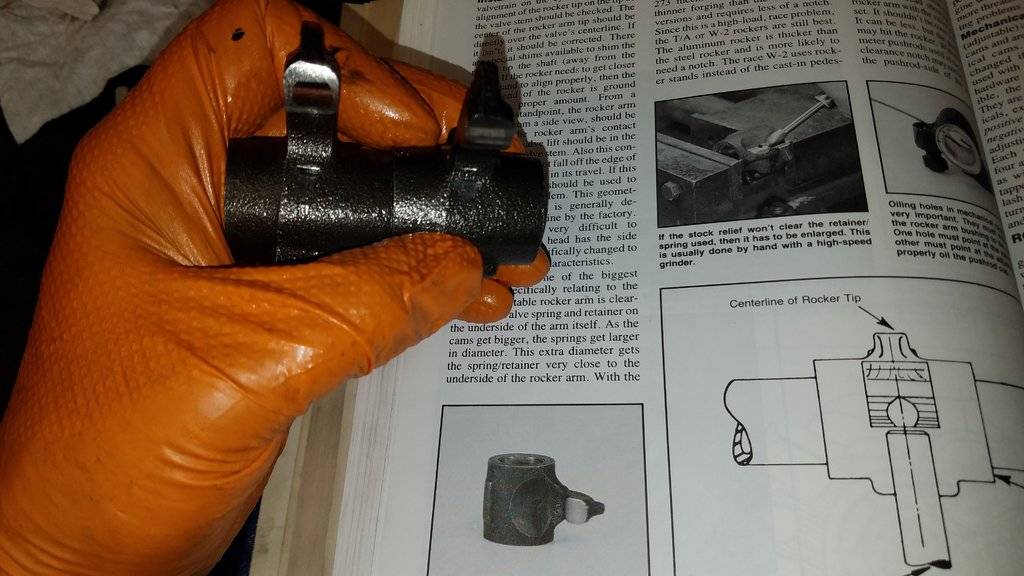

ok here is an update. i took off the rocker shaft assembly and inspected everything. i think i found the source of some of the metal. The inside radius underneath of the 273 rocker arm occasionally rubs on the valve spring and it is self clearancing. i found a page in one of my books that talks about this (PO didnt have this book apparently).

Also found one push rod bent and it has been hammered on so much that the ball socket came off the push rod. I checked all the push rods by putting them in my drill press and spinning them, i only found one straight one. so obviously there is an adjustment problem here.

I am going to order a new set of push rods and those rocker adjusters that come with a jam nut so the settings dont come loose and move the adjuster screw

I have hydraulic lifters, my cam card specifies that and it also specified 0 lash for both in/ex. So how do i set a zero lash with hydraulic lifters (when i slide the feeler gage in there it just compresses the hydraulic lifter)

The wear on the rocker arms and shafts, i believe i can polish that out and it will be fine, with the new parts i should be able to keep the lash set to where it should be and this would solve all the problems. I will also have to clearance out those rocker arms where they are rubbing on the valve springs.

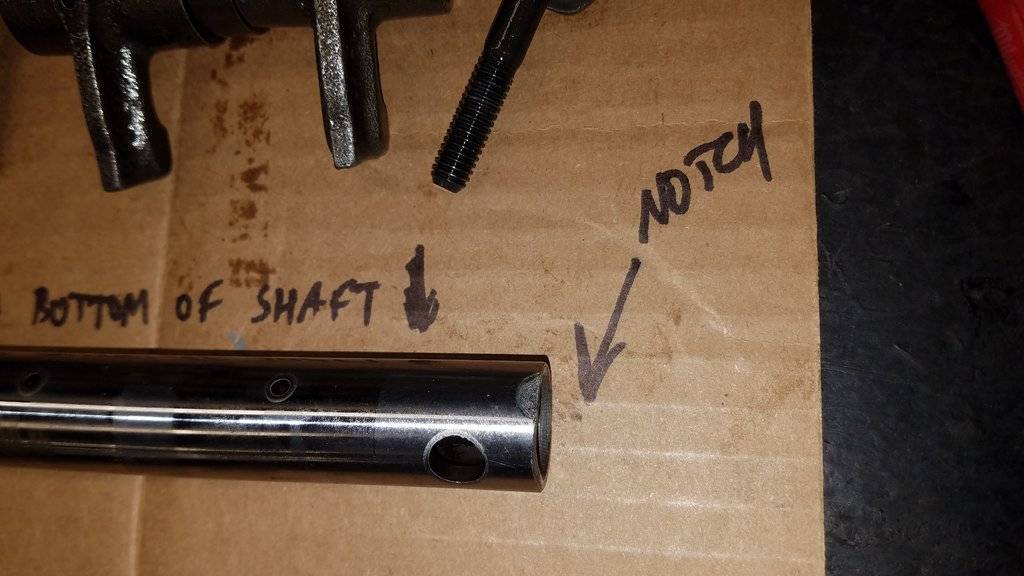

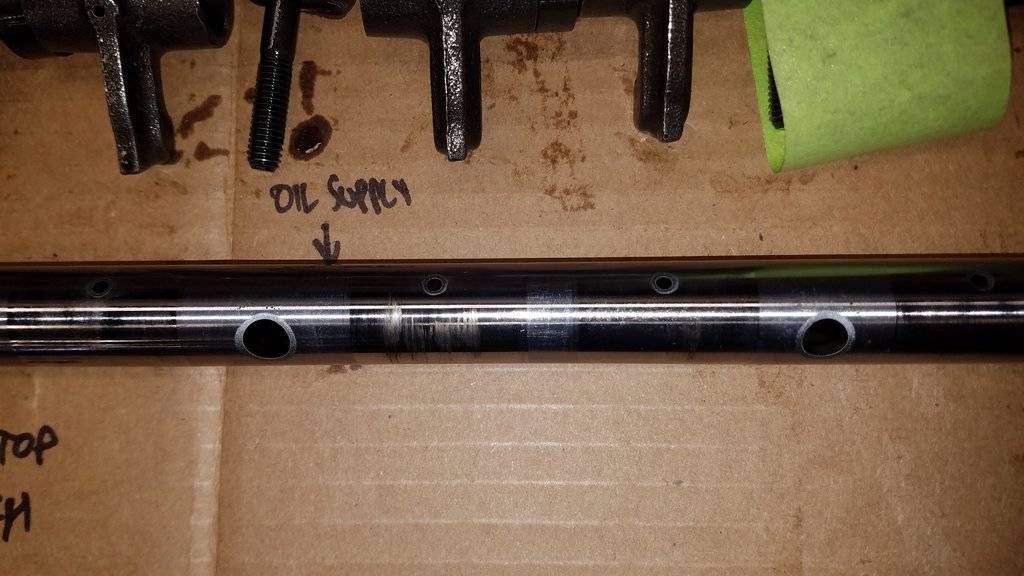

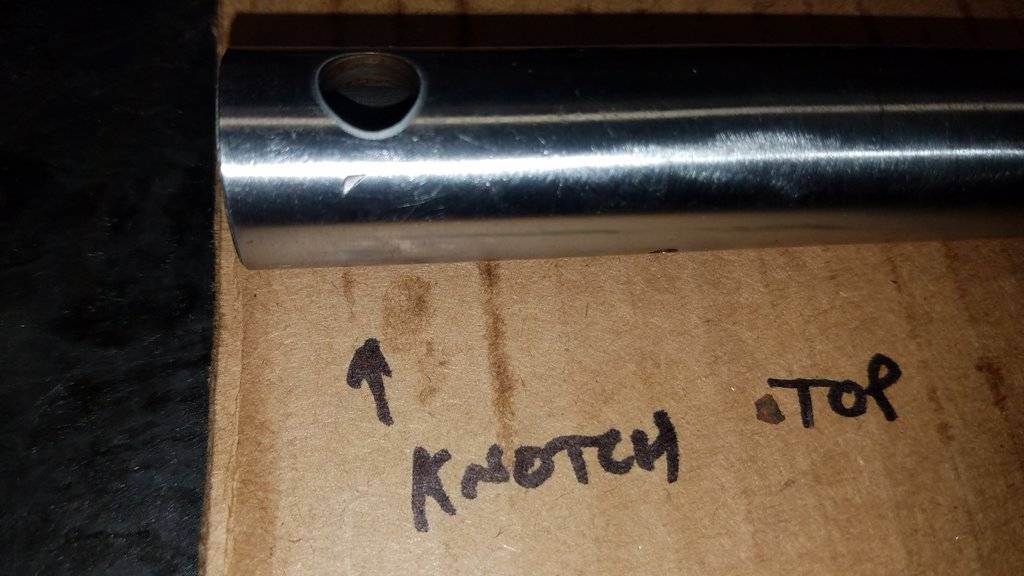

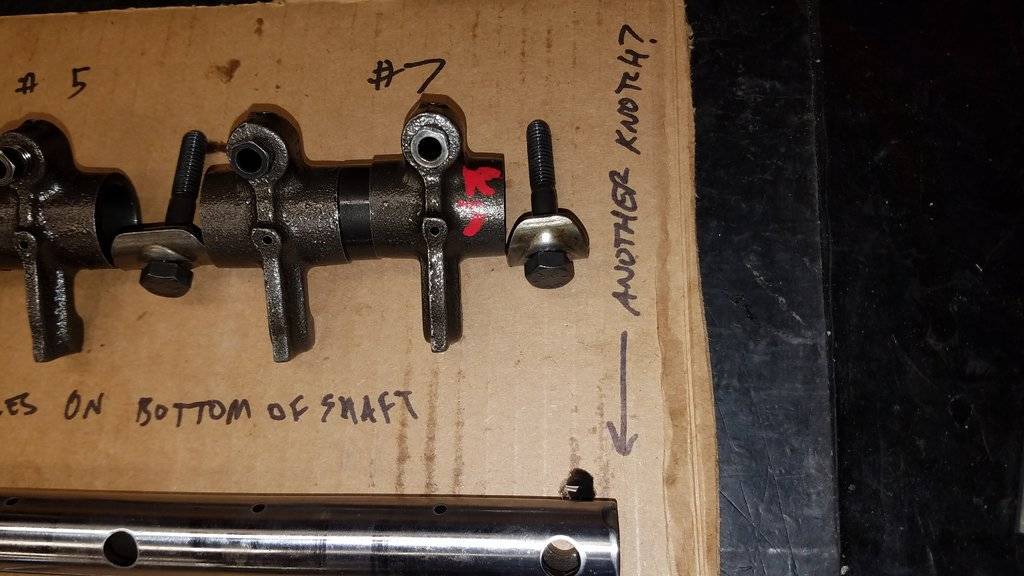

Knotches...is there any rhyme or reason on their knoctching of the rocker shafts?

Front left top shaft has a punch style knotch. then the bottom rear of the shaft has a milling machine knotch.

Front rocker shaft has no knotches on the top, but has a milling machine knotch at the bottom front.

Thanks for your input and help

ok here is an update. i took off the rocker shaft assembly and inspected everything. i think i found the source of some of the metal. The inside radius underneath of the 273 rocker arm occasionally rubs on the valve spring and it is self clearancing. i found a page in one of my books that talks about this (PO didnt have this book apparently).

Also found one push rod bent and it has been hammered on so much that the ball socket came off the push rod. I checked all the push rods by putting them in my drill press and spinning them, i only found one straight one. so obviously there is an adjustment problem here.

I am going to order a new set of push rods and those rocker adjusters that come with a jam nut so the settings dont come loose and move the adjuster screw

I have hydraulic lifters, my cam card specifies that and it also specified 0 lash for both in/ex. So how do i set a zero lash with hydraulic lifters (when i slide the feeler gage in there it just compresses the hydraulic lifter)

The wear on the rocker arms and shafts, i believe i can polish that out and it will be fine, with the new parts i should be able to keep the lash set to where it should be and this would solve all the problems. I will also have to clearance out those rocker arms where they are rubbing on the valve springs.

Knotches...is there any rhyme or reason on their knoctching of the rocker shafts?

Front left top shaft has a punch style knotch. then the bottom rear of the shaft has a milling machine knotch.

Front rocker shaft has no knotches on the top, but has a milling machine knotch at the bottom front.

Thanks for your input and help