lifter galley crossover tube

Found this on the internet

Well ok between the two post about creating a low pressure point being mentioned do we have an agreement that you can have full oil pressure at your gauge and certain areas starving for oil because of low pressure?

I may be mistaken but I do not believe that I gave velocity as the cause of the 2&4 mains.

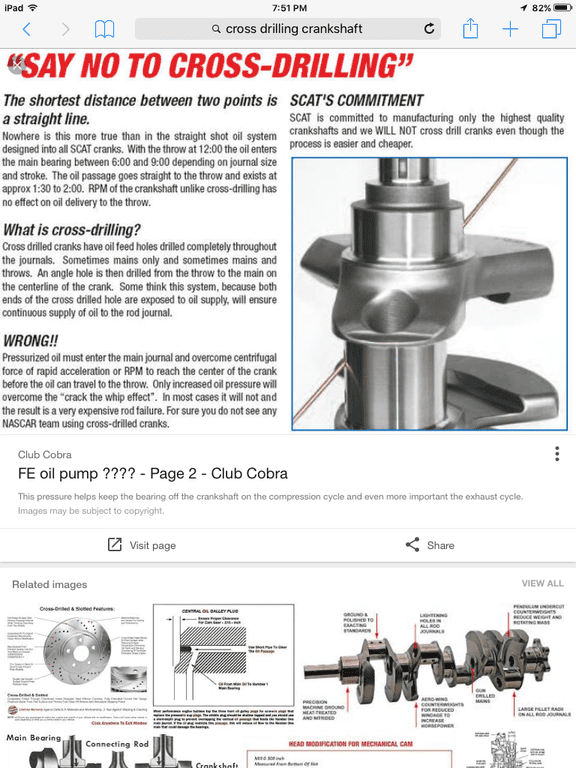

You are correct there is no point in grooving the cam grooves as this hurts the main bearings. As I said most cam manufacturers no longer do this. It was another tried in the past experiment that does not help, just like cross drilling.

I believe that older Chevy small blocks were fed from a center galley that was not used to feed the lifters and that this galley was dead ended at the end so no velocity issues there.

In a previous post I mentioned that the plug being added at the end of the galley is not discussed enough.

The cross over tube method and the tubing the block method both have in common adding a plug to dead end the system. The only difference is where the plug is. One is over top of #1 main feed passage and the other is in front of it with the #1 passage blocked from the #1 main bearing. This plug also helps stop the velocity.

You are correct that the rocker oiling mod by itself does not make the block into a priority main oil system. But it is a step towards it.

It is my understanding that an "R" block does not come with any feed passages drilled to the lifters so you do not have to tube the block.

Lifter oiling is always optional on a full race motor.

Regarding the straight shot oiling I also mentioned that the location of the oil holes has been refined. Not that it was new.

There is a trend now towards oiling the rockers with external lines tapped into the main galley. I believe Jim sizilgys jumper tube mod accomplishes the same thing.

Found this on the internet