69 Notch Barracuda - Rebirth

Valley pan and intake mount holes, as well as the tops of the ports (pencil lines across the tops of the intake runners and heads to look for a match), lined up perfectly. Chased the carb mount hole threads in the intake before final install. Cleaned all metal surfaces with mineral spirits. Also made my own valley pan rail hold-downs with 3/4" X 1/8" Aluminum stock from Menards.

Copper coated the valley pan, top and bottom (where it meets the metal).

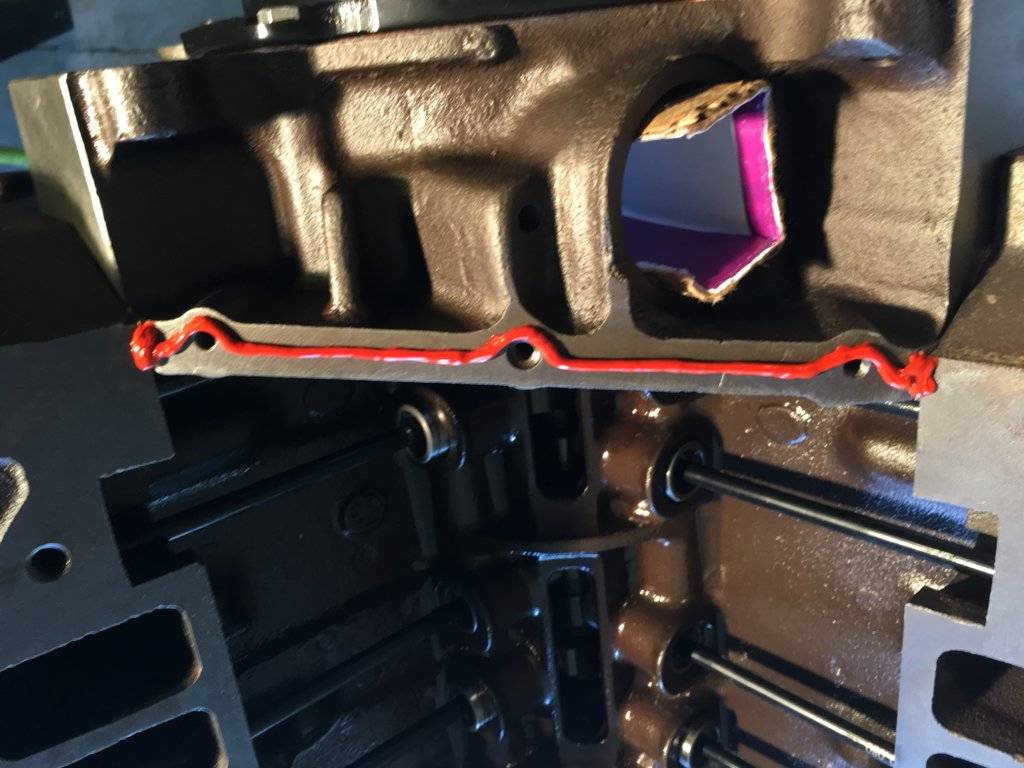

Put a small bead of high temp Red RTV along the front and back rails, with an extra dab on each corner.

All went excellent, except for the fact that I forgot to use the lesser torque values for the valley pan bolts (front and back), and the intake bolts. I've been doing great remembering to check the appropriate, lesser-value torque figure up until this point. My bolt kit is stainless from Alloy Boltz Inc., and they require less torque than stock bolts. I always use the Aluminum antisieze, however. Hopefully the small amount of over-torque won't be a big deal. I just made a note of it. I didn't feel like it was worth starting all over and possibly needin a new valley pan.

Also... dry fitted the water pump on at the end of the day. The harmonic balancer seems to rub the Chrysler water pump. Is it pretty common to have to grind some material off of the water pump for HB clearance?

- Pushrods (Trick Flow Chromoly 8.500")

- Rockers (stamped stock)

- Valley pan

- Intake manifold (Performer RPM)

Valley pan and intake mount holes, as well as the tops of the ports (pencil lines across the tops of the intake runners and heads to look for a match), lined up perfectly. Chased the carb mount hole threads in the intake before final install. Cleaned all metal surfaces with mineral spirits. Also made my own valley pan rail hold-downs with 3/4" X 1/8" Aluminum stock from Menards.

Copper coated the valley pan, top and bottom (where it meets the metal).

Put a small bead of high temp Red RTV along the front and back rails, with an extra dab on each corner.

All went excellent, except for the fact that I forgot to use the lesser torque values for the valley pan bolts (front and back), and the intake bolts. I've been doing great remembering to check the appropriate, lesser-value torque figure up until this point. My bolt kit is stainless from Alloy Boltz Inc., and they require less torque than stock bolts. I always use the Aluminum antisieze, however. Hopefully the small amount of over-torque won't be a big deal. I just made a note of it. I didn't feel like it was worth starting all over and possibly needin a new valley pan.

Also... dry fitted the water pump on at the end of the day. The harmonic balancer seems to rub the Chrysler water pump. Is it pretty common to have to grind some material off of the water pump for HB clearance?