273 302 318 340 build

Dropped by machinist as there was one con rod/piston pin that had an ever so slight wiggle. He measured and its good. So next is piston and con rod install. A couple questions...I've been looking for info on proper ring gap orientation. Seems the net, books are all different.

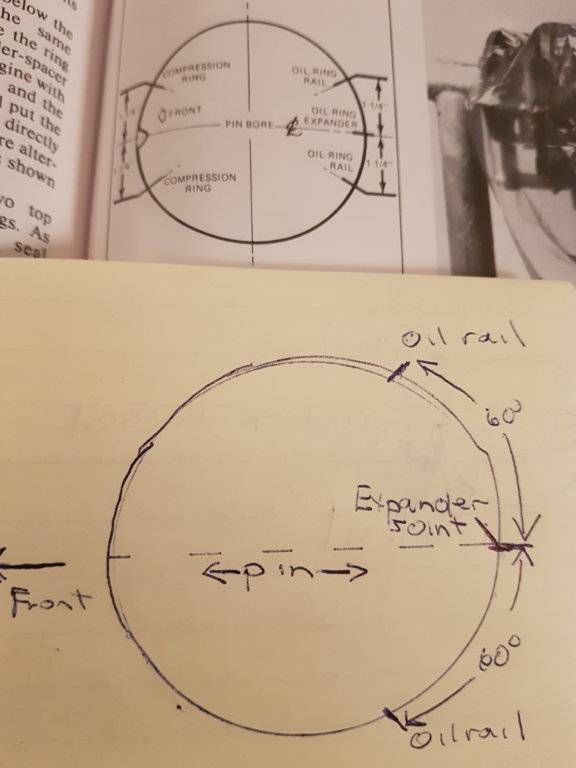

Machinist says expander joint in line with pin bore, then oil rails 60* off in both directions from expander joint. (See my drawing below).

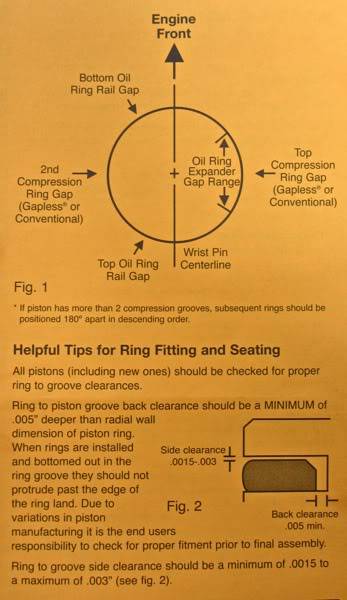

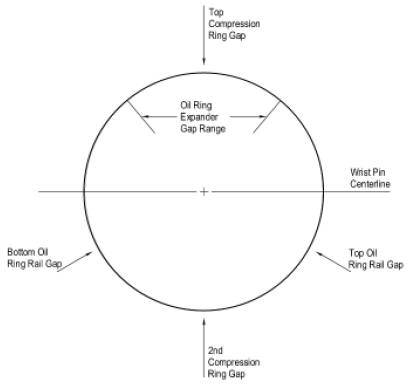

I forgot to ask proper spacing for on the compression rings. Suggestions?

See pics attached, they all vary lol

Also any special paste/lube for piston skirts?

Thanks all!

Dropped by machinist as there was one con rod/piston pin that had an ever so slight wiggle. He measured and its good. So next is piston and con rod install. A couple questions...I've been looking for info on proper ring gap orientation. Seems the net, books are all different.

Machinist says expander joint in line with pin bore, then oil rails 60* off in both directions from expander joint. (See my drawing below).

I forgot to ask proper spacing for on the compression rings. Suggestions?

See pics attached, they all vary lol

Also any special paste/lube for piston skirts?

Thanks all!