273 302 318 340 build

Some progress and more measuring to come lol.

Got to use ring expander and ring compressor. Installed #1 Piston.

Cleaned pin and bore. Installed pin lock (**flat side out**).

Lubed pin up, and aligned rod so numbers face out, and relief valves face in.

WD40 the expander and oil the rails and compression ring

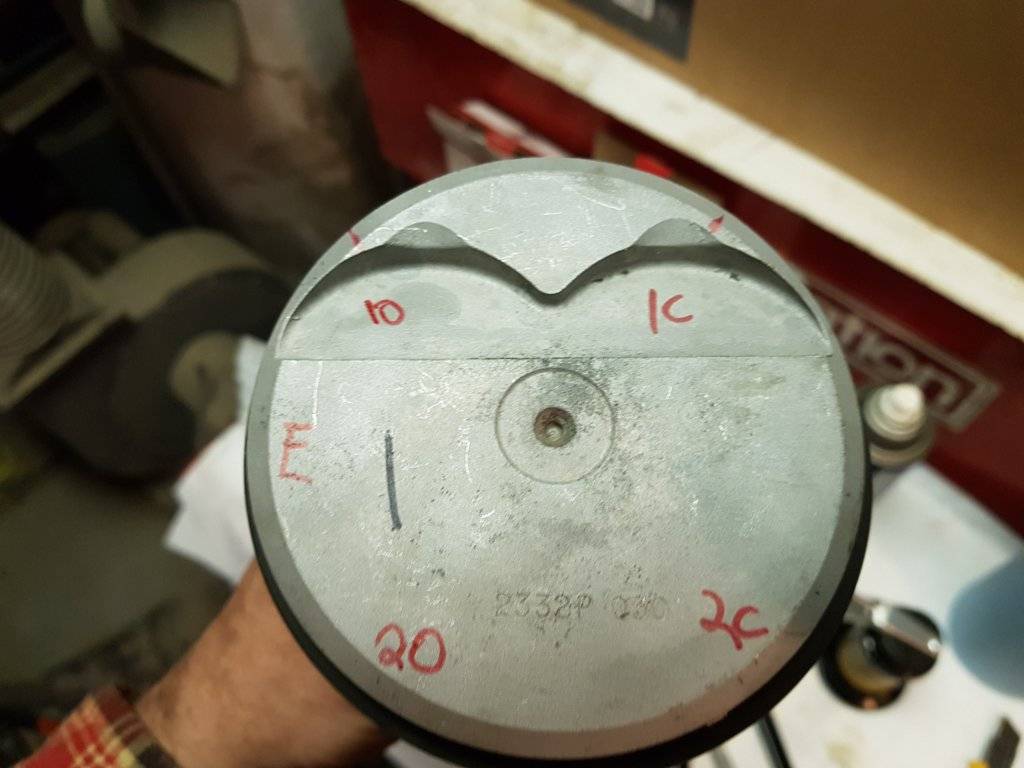

Marked piston top with the ring gap orientation.

Expander(butted not overlapped) parallel to pin.

Each oil rails offset 45* from expander.

Top ring approx 1:30

2nd ring approx 4:30

I will mark the top of the remaining pistons to "speed up" ring install. Nerve wracking putting top 2 rings on lol. For the remaining 7 pistons I will set in a vice for stability.

Wasn't too happy with Lisle piston ring compressor....tight as heck. Hopefully it loosens up a bit.

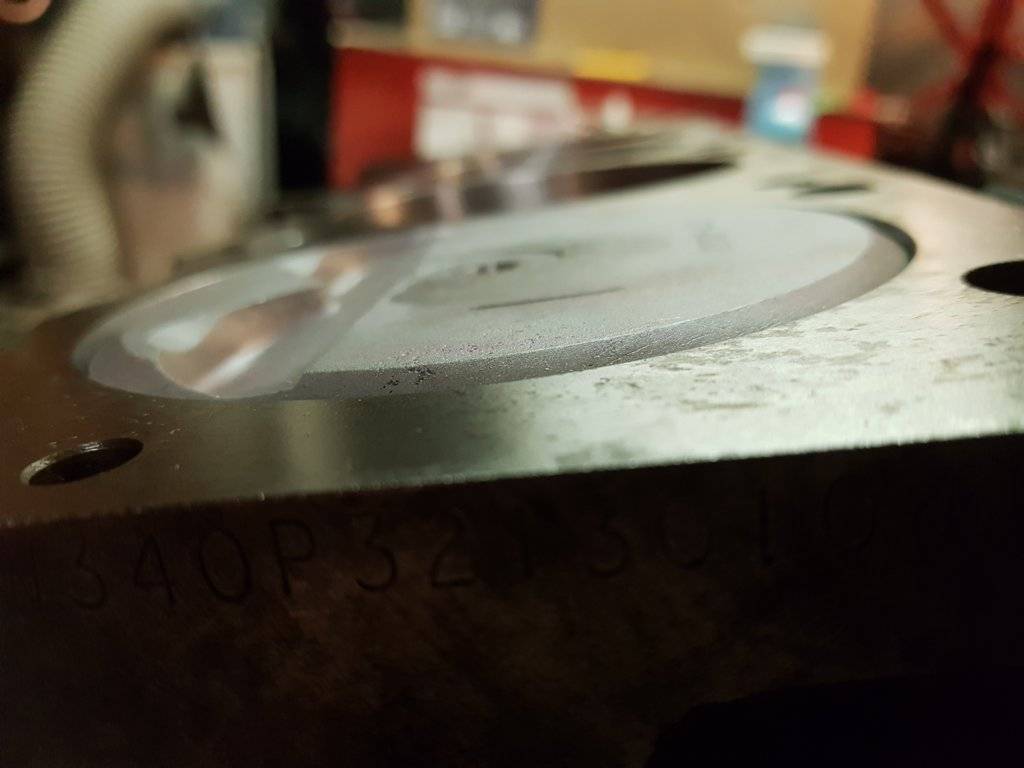

Not a lotta progress but I can now see where the slug sits...in or outta the hole. Closer to fingering actual compression

Thanks all!

Some progress and more measuring to come lol.

Got to use ring expander and ring compressor. Installed #1 Piston.

Cleaned pin and bore. Installed pin lock (**flat side out**).

Lubed pin up, and aligned rod so numbers face out, and relief valves face in.

WD40 the expander and oil the rails and compression ring

Marked piston top with the ring gap orientation.

Expander(butted not overlapped) parallel to pin.

Each oil rails offset 45* from expander.

Top ring approx 1:30

2nd ring approx 4:30

I will mark the top of the remaining pistons to "speed up" ring install. Nerve wracking putting top 2 rings on lol. For the remaining 7 pistons I will set in a vice for stability.

Wasn't too happy with Lisle piston ring compressor....tight as heck. Hopefully it loosens up a bit.

Not a lotta progress but I can now see where the slug sits...in or outta the hole. Closer to fingering actual compression

Thanks all!