P4120701 Small Block Mech Tach drive

You will need more than 'about' 1000 rpm with those distributors. They can appear to be 'all in' at very low rpm.

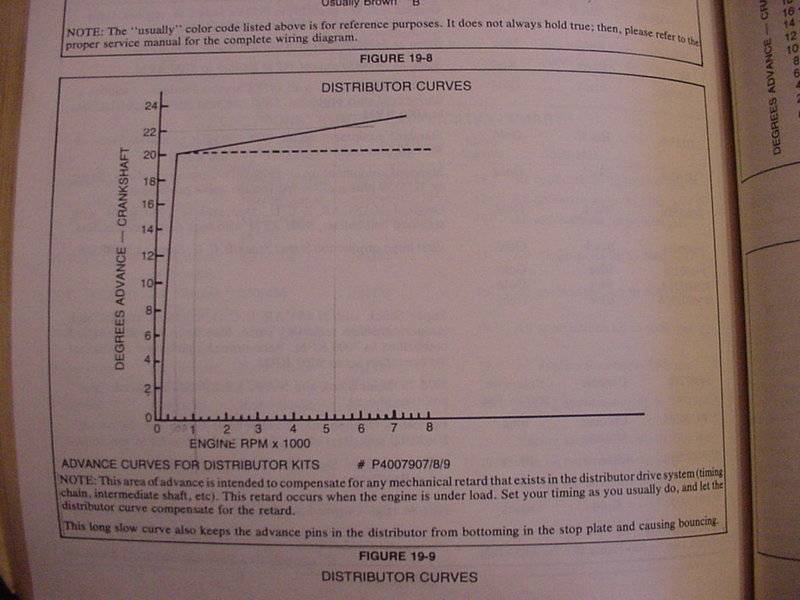

Without that, or even with that, check the springs - in particular the primary spring. Someone may have set it up for to locked, or someone could have put even a faster advancing primary spring in. According to the Direct Connection bulletin, they should hit the secondary spring around 600 rpm. On mine, it appears to nearly stop advancing between 1200 and 1700 rpm. From there on up it is flat.

The idea is to set them up for best timing at working rpm. You can use 2500 or 3000 rpm, or even less depending on the spring since its pertty much a flat line you can count on. A long quick curve assures easy starts even when hot. If its 36 degrees at 3000 rpm, then is around 10 degrees at starting rpms. Those were the priorities for back then, and the focus was drag racing. If you want a stable timing at idle, more tension or a different primary spring will be needed. Leave the big one along - thats part of the secret so the engine doesn't see the lag in electronics at high rpm (talking 5000 rpm up here, not street rpms).

(I know they talk about the 'mechanical lag' but a good portion of it is the time it takes for each electronic component to switch and send a signal. Nothing to notice even at 3000 rpm, but at 6000 rpm that time can add up to 2 or 3 degrees. Some electronics are faster so its less noticible, and a few electronic boxes are designed to compensate.)

You will need more than 'about' 1000 rpm with those distributors. They can appear to be 'all in' at very low rpm.

Without that, or even with that, check the springs - in particular the primary spring. Someone may have set it up for to locked, or someone could have put even a faster advancing primary spring in. According to the Direct Connection bulletin, they should hit the secondary spring around 600 rpm. On mine, it appears to nearly stop advancing between 1200 and 1700 rpm. From there on up it is flat.

The idea is to set them up for best timing at working rpm. You can use 2500 or 3000 rpm, or even less depending on the spring since its pertty much a flat line you can count on. A long quick curve assures easy starts even when hot. If its 36 degrees at 3000 rpm, then is around 10 degrees at starting rpms. Those were the priorities for back then, and the focus was drag racing. If you want a stable timing at idle, more tension or a different primary spring will be needed. Leave the big one along - thats part of the secret so the engine doesn't see the lag in electronics at high rpm (talking 5000 rpm up here, not street rpms).

(I know they talk about the 'mechanical lag' but a good portion of it is the time it takes for each electronic component to switch and send a signal. Nothing to notice even at 3000 rpm, but at 6000 rpm that time can add up to 2 or 3 degrees. Some electronics are faster so its less noticible, and a few electronic boxes are designed to compensate.)