P4120701 Small Block Mech Tach drive

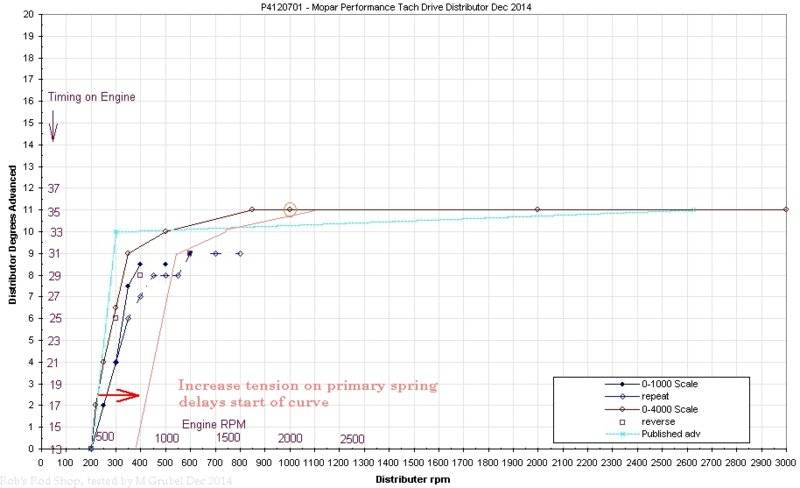

Here's what adjusting the spring perches can do.

First drawing shows that more tension on the primary spring holds the weight from moving until a higher rpm. In this example, 500 to 800 rpm. That would get 31* at 1000, and 35* just over 2000 rpm.

Now imagine if it was delayed even more, say to 1000 rpm. Then the timing at 2500 rpm would still be set at 35*, but when at 1000 rpm, timing will be 13*. That's OK for with stock cam, but really not enough with a longer duration, higher overlap cam.

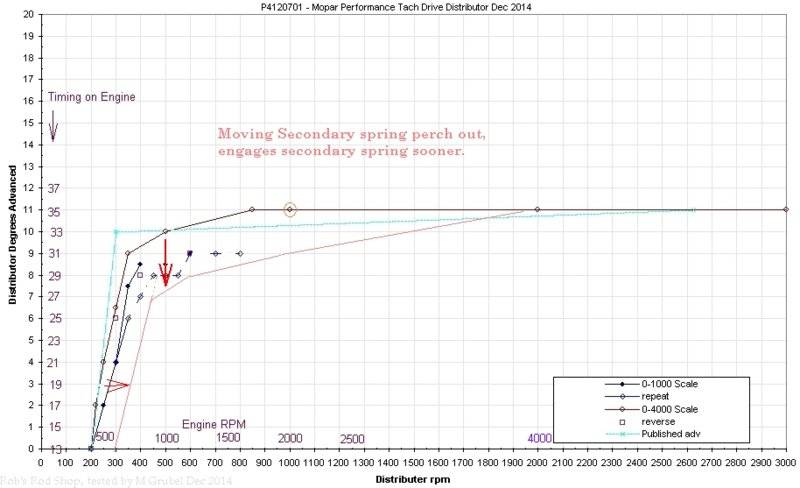

Instead, what might might work better is only increase the primary spring tension a little. Also move the secondary perch out. This will get the secondary spring engaged earlier. Result would look something like this.

Here the timing at 1000 rpm is around 27* and it will still be at 35* by 4000 rpm.

Under 1000 rpm will be a little unstable. With a 4 speed, no big deal - with an automatic, it can be a little annoying for some people. That's because it will lose rpm going unto gear at say 900 rpm, and lose timing at the same time. This will causew it to lose even more rpm.

Here's what adjusting the spring perches can do.

First drawing shows that more tension on the primary spring holds the weight from moving until a higher rpm. In this example, 500 to 800 rpm. That would get 31* at 1000, and 35* just over 2000 rpm.

Now imagine if it was delayed even more, say to 1000 rpm. Then the timing at 2500 rpm would still be set at 35*, but when at 1000 rpm, timing will be 13*. That's OK for with stock cam, but really not enough with a longer duration, higher overlap cam.

Instead, what might might work better is only increase the primary spring tension a little. Also move the secondary perch out. This will get the secondary spring engaged earlier. Result would look something like this.

Here the timing at 1000 rpm is around 27* and it will still be at 35* by 4000 rpm.

Under 1000 rpm will be a little unstable. With a 4 speed, no big deal - with an automatic, it can be a little annoying for some people. That's because it will lose rpm going unto gear at say 900 rpm, and lose timing at the same time. This will causew it to lose even more rpm.