1968 Dodge A100 re-born ...again....

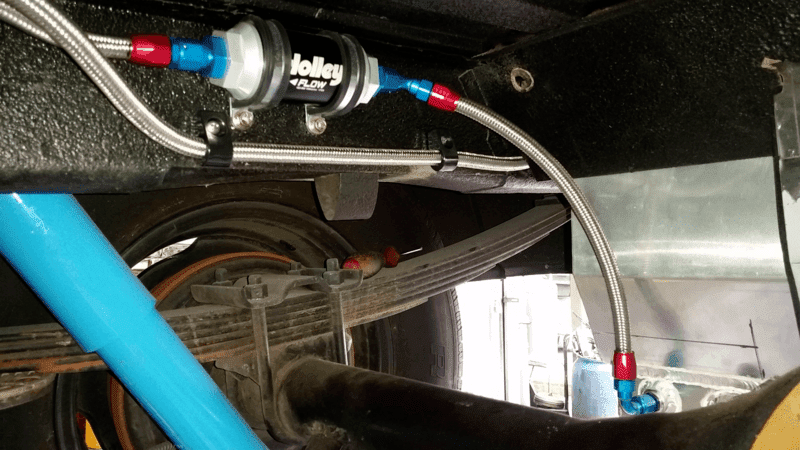

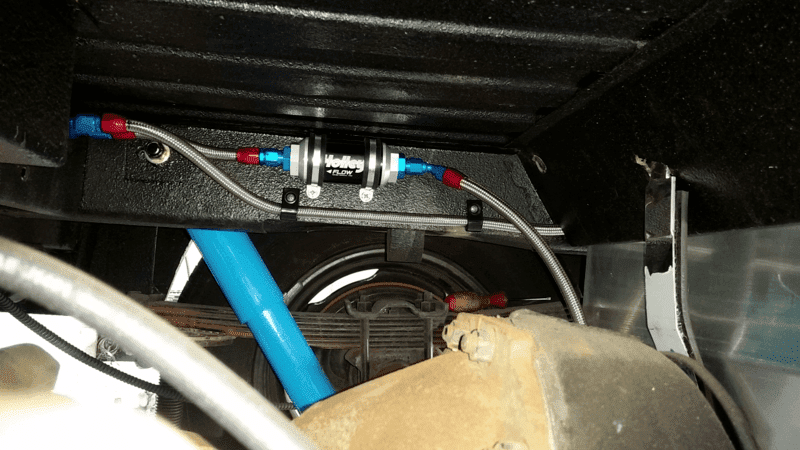

Fuel line work was next...before the engine and transmission are installed...

Used a bunch of Earl's fittings and braided hose for ease of disassembly on the side of the road etc....just thinking ahead. :D

Below there is a 3-inch bulkhead to pass through, so a frantic search on the Innerweb found a company in Arizona...a phone call and a transaction was done. Within 6 days I had the bulkhead fittings required....thanks guys.

http://www.purechoicemotorsports.co...ct_id=346/category_id=74/mode=prod/prd346.htm

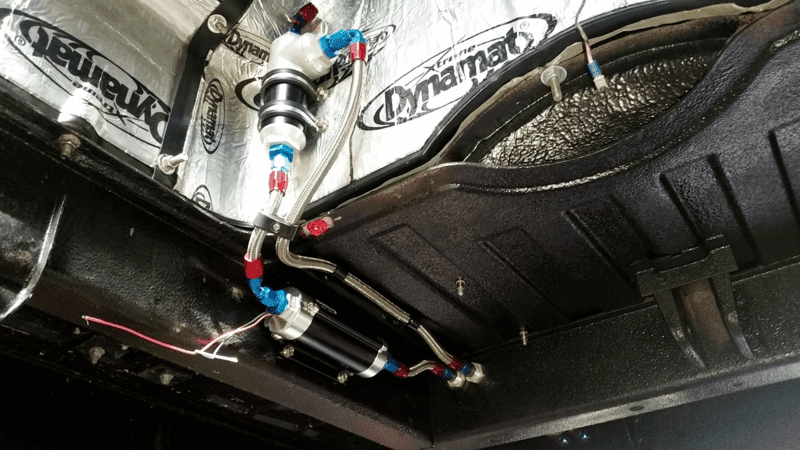

We actually ended up having major problems with the flash new Holley billet pump - failed within 10 minutes of road test....a second one also failed within 10 minutes on the road test. The solution was to remove the Holley pump AND Filter/Regulator, and run a Bosch pump, and the return line directly from the Sniper. There appears to be some confusion in a Holley bulletin suggesting you can save on a return line by using a Filter/Regulator - this is the wrong way to pipe out a Sniper. The return line MUST run direct from the Sniper to the tank....no exceptions. This gives full pressure to the Sniper as well as allowing a cooling effect on the Throttle Body itself with the flow of fuel. As we didn't have anyone local to tap into for knowledge, this really was a 'Learn as you go' experience. All sorted out now, and the engine runs great.

I have included the picture above to show that we had to dissect the Holley pump to determine the problem...the biggest problem appears to be a poor design.

Fuel line work was next...before the engine and transmission are installed...

Used a bunch of Earl's fittings and braided hose for ease of disassembly on the side of the road etc....just thinking ahead. :D

Below there is a 3-inch bulkhead to pass through, so a frantic search on the Innerweb found a company in Arizona...a phone call and a transaction was done. Within 6 days I had the bulkhead fittings required....thanks guys.

http://www.purechoicemotorsports.co...ct_id=346/category_id=74/mode=prod/prd346.htm

We actually ended up having major problems with the flash new Holley billet pump - failed within 10 minutes of road test....a second one also failed within 10 minutes on the road test. The solution was to remove the Holley pump AND Filter/Regulator, and run a Bosch pump, and the return line directly from the Sniper. There appears to be some confusion in a Holley bulletin suggesting you can save on a return line by using a Filter/Regulator - this is the wrong way to pipe out a Sniper. The return line MUST run direct from the Sniper to the tank....no exceptions. This gives full pressure to the Sniper as well as allowing a cooling effect on the Throttle Body itself with the flow of fuel. As we didn't have anyone local to tap into for knowledge, this really was a 'Learn as you go' experience. All sorted out now, and the engine runs great.

I have included the picture above to show that we had to dissect the Holley pump to determine the problem...the biggest problem appears to be a poor design.