1972 Duster Build with my Daughter

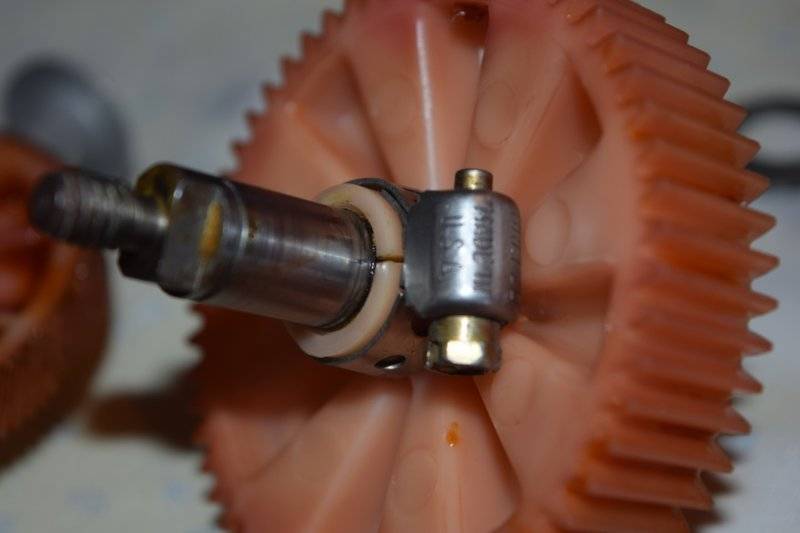

So here is what I did... since I know glue/epoxy won't stick to this engineering plastic. The Chrysler engineers where nice enough to put a clamp shelf on the gear for us. You can see the crack in the gear on this side too.

All fixed. Now it was time to spend a few hours in the garage with the bead blaster (best damn investment you can EVER make when restoring cars even the little $100 Harbor Freight one is great after you add lighting to it).

Put the brush holder back on and snap it down with 1/8" x 3/16" or so rivets.

Now slide the armature down and use 3 hands to hold the brushes back. Grease the bushing and wave washer wear surfaces.

Slide the idler gear on the post in the front clamshell. SAVE THE GREASE FROM THE GEARS... Plastic compatible grease is a complex topic. Assume the Chrysler engineers did all the homework for you and only grease the plastic with what they used.

Notice the lump in the main gear. Make sure you don't try to insert it with the stop cam facing the stop switch. Rotate it 180 degrees when you put it all together.

Install a skinny washer to the shaft and insert the gear in the rear clamshell.

Next on goes the second skinny washer.

So here is what I did... since I know glue/epoxy won't stick to this engineering plastic. The Chrysler engineers where nice enough to put a clamp shelf on the gear for us. You can see the crack in the gear on this side too.

All fixed. Now it was time to spend a few hours in the garage with the bead blaster (best damn investment you can EVER make when restoring cars even the little $100 Harbor Freight one is great after you add lighting to it).

Put the brush holder back on and snap it down with 1/8" x 3/16" or so rivets.

Now slide the armature down and use 3 hands to hold the brushes back. Grease the bushing and wave washer wear surfaces.

Slide the idler gear on the post in the front clamshell. SAVE THE GREASE FROM THE GEARS... Plastic compatible grease is a complex topic. Assume the Chrysler engineers did all the homework for you and only grease the plastic with what they used.

Notice the lump in the main gear. Make sure you don't try to insert it with the stop cam facing the stop switch. Rotate it 180 degrees when you put it all together.

Install a skinny washer to the shaft and insert the gear in the rear clamshell.

Next on goes the second skinny washer.