A few pics of barracuda project.

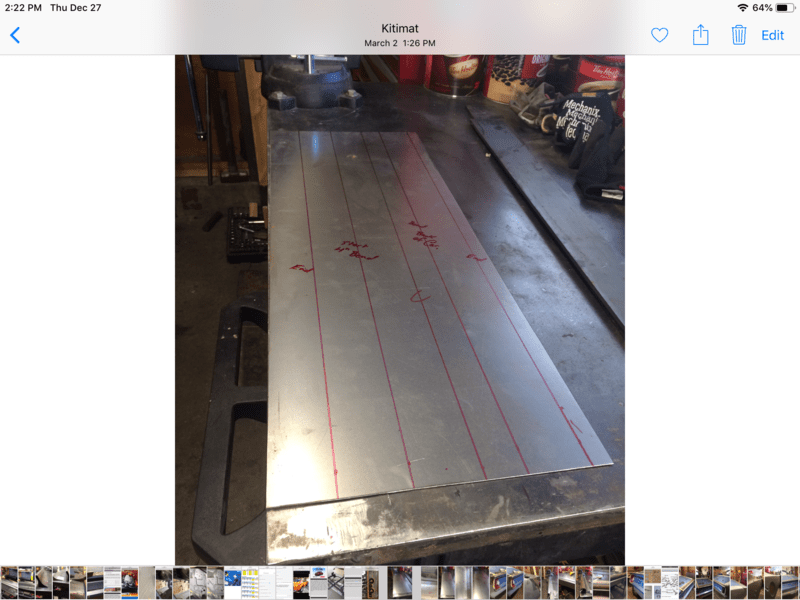

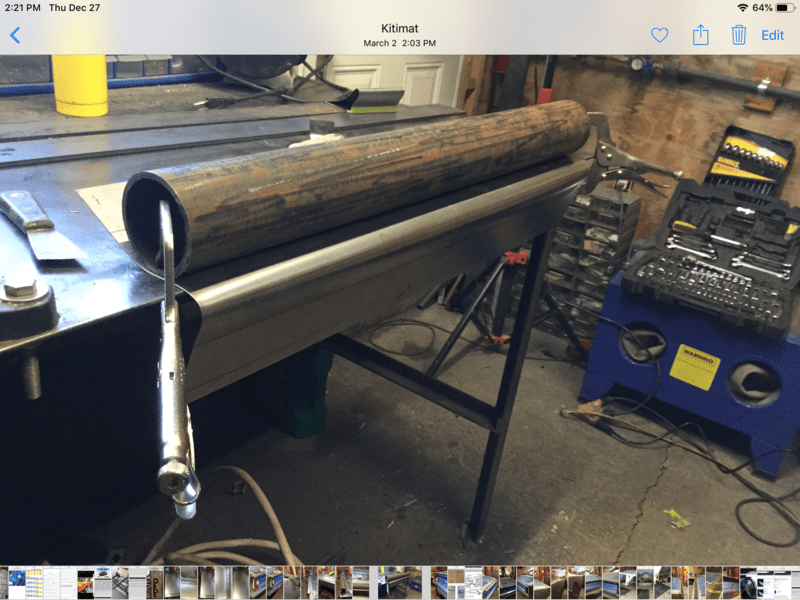

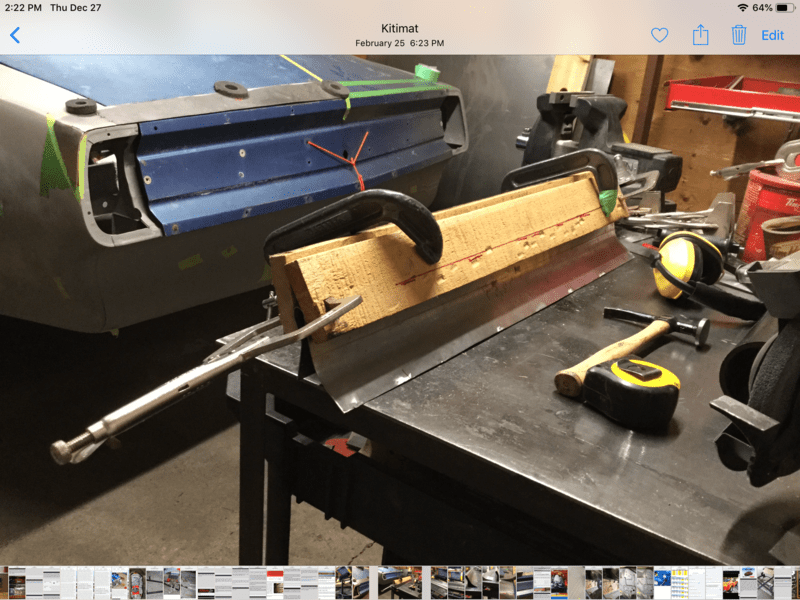

Used 18 gauge mild steel, probably could have used 20. 20 is a much easier too wrk with. Too get the radius for the the chin spoiler I just marked the center of metal I was using, then bent it over a peace of electrical conduit. After the metal mostly shaped, i clamped it with plywood on each side and finished the bend with c clamps. There is a easier way if you have access to a metal brake. If you just loosen off the brake edge the same on both sides, you get a nice consistent round bend instead of being sharp. One side of my chin spoiler was bent by hand and the other was on a brake. It took two try’s too match the hand built one. Sure would be nice to own a metal brake, life would be a lot easier. My rear spoiler was totally made by hand, plywood and clamps. Also used a little heat when bending. When I bent the rear spoiler back towards the car a clamp a 4 in pipe to my work bench over the metal. This gave me a nice gentle bend that was desired.