1972 Duster Build with my Daughter

Also much different than the Coronet was the vacuum valve. This is a rubber maze that slides across holes to route vacuum to different places... The springs and the detents press the rubber into the smooth surface to make a seal.

The vacuum holes into the rubber maze is about 0.032" or a #67. I had to fix a nipple with super glue so I cleaned out all the holes while I was at it.

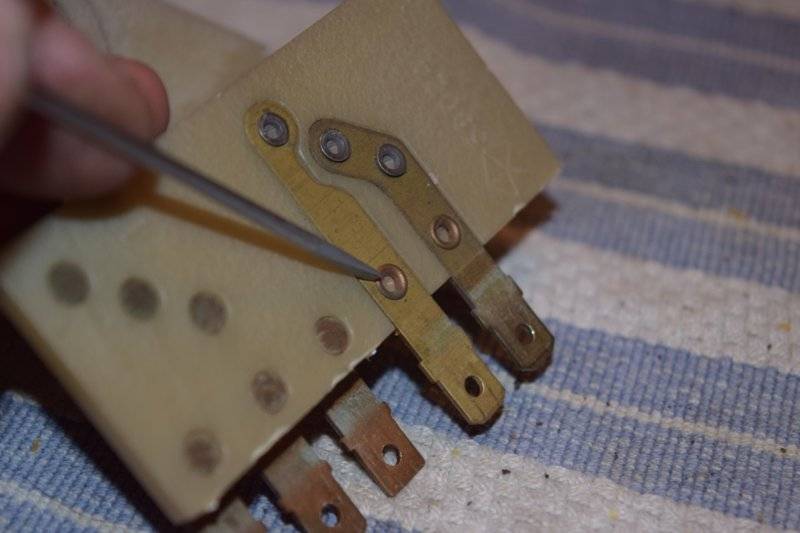

Here is the source of poor electrical connections and harness fires. The Coronet has smoke coming out from under the dash due to a poor connection here. That is where I learned these switches are really easy to fix.

Here is the points type contacts that change as the AC/heater mode is changed.

Dunk this part of the switch in vinegar. It will etch and clean the connections where the rivets are. Once done neutralize it by soaking it in water and baking soda (I have a few cases of Red Devil lye that I bought when I heard they were not longer make it anymore).

After this the connection was very good but this make it permanent. Note the steal rivets do not solder well so be careful you don't melt the plastic and ruin the point contact on the other side.

All I need to do now is to drill and tap some screws.. Problem is I am low on stock of my #00-90, #0-80 and #2-56 screws that I use for my model trains. The Mopars have been taking 100% of my hobby time so that hobby the stock is low. I ordered a restock and should have them this week so I can finish this up.

Also much different than the Coronet was the vacuum valve. This is a rubber maze that slides across holes to route vacuum to different places... The springs and the detents press the rubber into the smooth surface to make a seal.

The vacuum holes into the rubber maze is about 0.032" or a #67. I had to fix a nipple with super glue so I cleaned out all the holes while I was at it.

Here is the source of poor electrical connections and harness fires. The Coronet has smoke coming out from under the dash due to a poor connection here. That is where I learned these switches are really easy to fix.

Here is the points type contacts that change as the AC/heater mode is changed.

Dunk this part of the switch in vinegar. It will etch and clean the connections where the rivets are. Once done neutralize it by soaking it in water and baking soda (I have a few cases of Red Devil lye that I bought when I heard they were not longer make it anymore).

After this the connection was very good but this make it permanent. Note the steal rivets do not solder well so be careful you don't melt the plastic and ruin the point contact on the other side.

All I need to do now is to drill and tap some screws.. Problem is I am low on stock of my #00-90, #0-80 and #2-56 screws that I use for my model trains. The Mopars have been taking 100% of my hobby time so that hobby the stock is low. I ordered a restock and should have them this week so I can finish this up.