Alternator repair, a little show and tell.

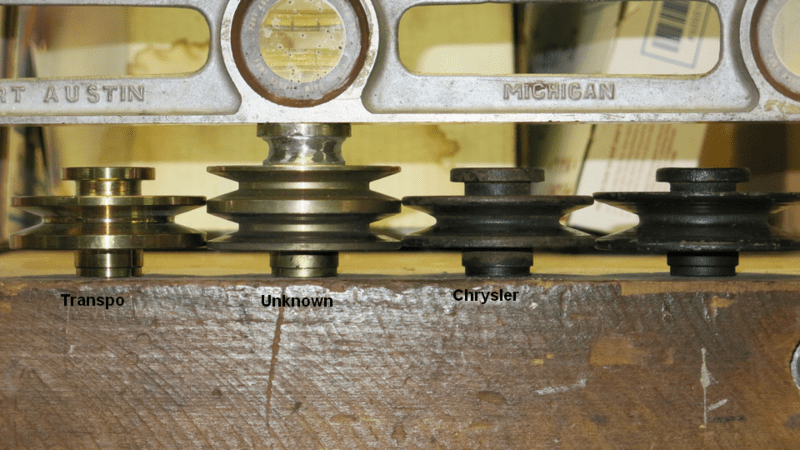

Pulley Alignment.

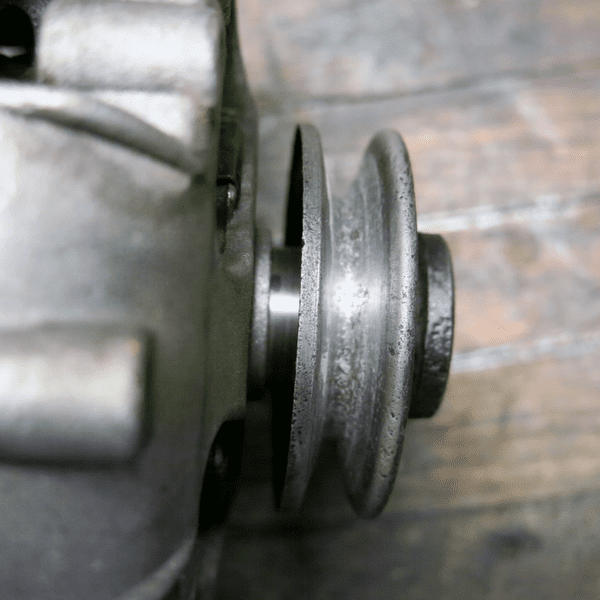

Pulleys get pressed on until the inside tip contacts the drive end bearing. As shown in the photo, the 2 V removed from the squareback was causing the belt alignment to be a bit off. The solid pulley on the far left weighed in at 1 lb. A factory pulley 7.5 oz, and the solid two groove pulley at 1 lb 7.5 oz after it underwent some weight reduction surgery.

Idealy you're supposed to press the pulley on with a pressure gage so you know when the pulley is contacting the bearing. Well I don't have one. An arbor press would have been nice, but I don't have one of the them either. So I measured the depth with the tail of vernier caliper and then marked the pulley. Then pressed it on.

The pulley has to be installed while the back half of the alternator housing is off.

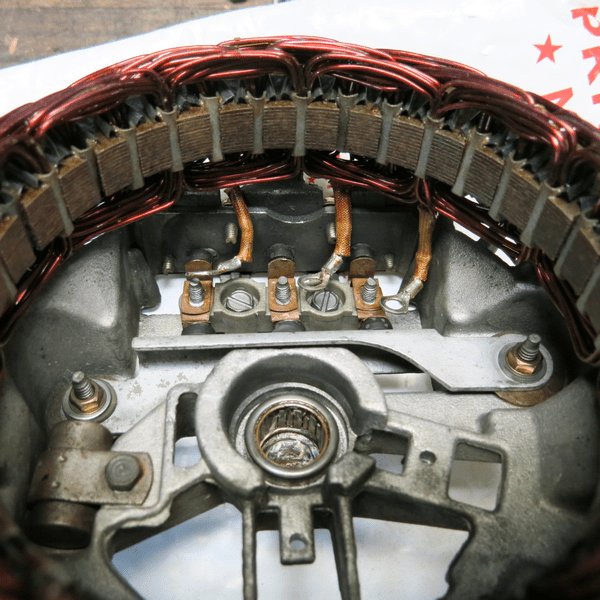

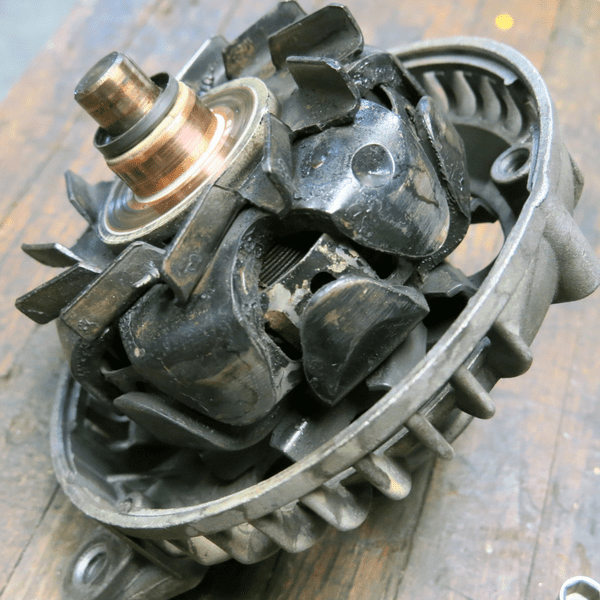

Installing a new stator took a bit of trial fitting. I didn't want the winding or attachment wires to rub the outer housing or touch the through bolts.

After installing the new stator, decided to take a quick look at the old one to see if it could be fixed.

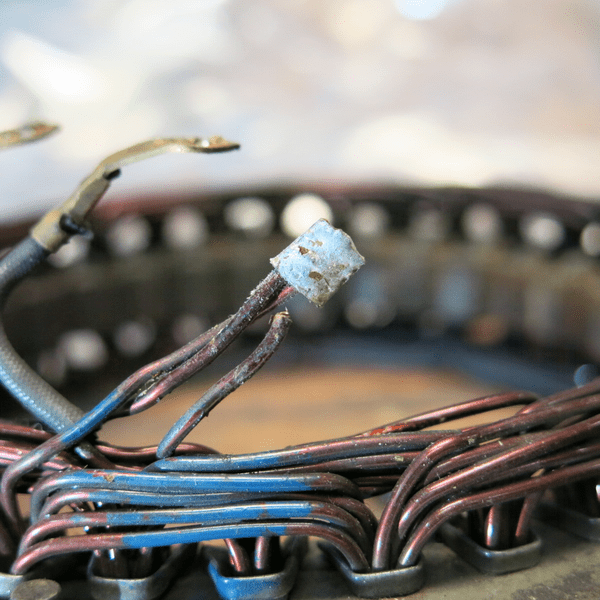

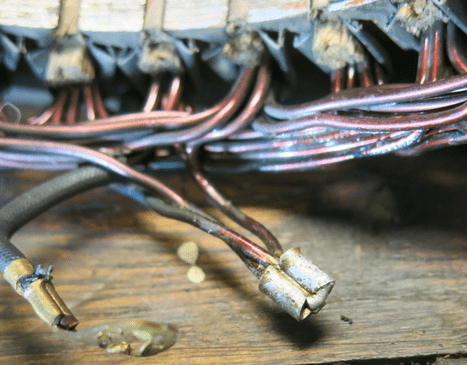

Removing the insulating tape or shink tubing from the Y connecting joint revealed the break.

Looks like there's enough wire to cut, clean and rejoin....when I have time at the garage...

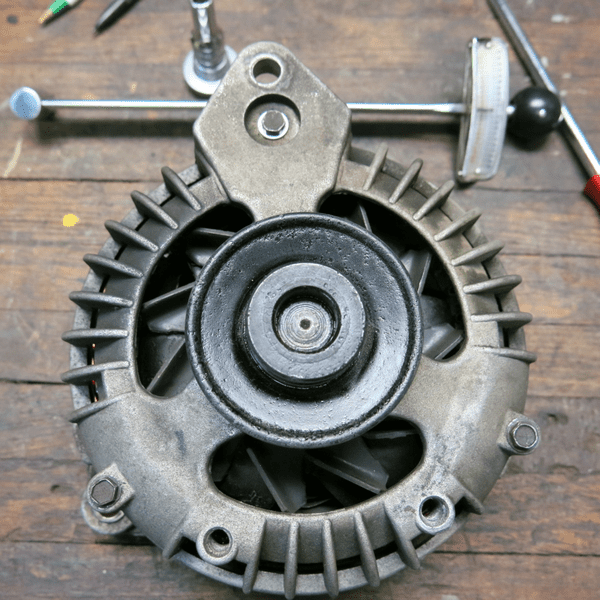

After reassembling the halves, all looked good,

But the rotor didn't want to turn freely :eek:

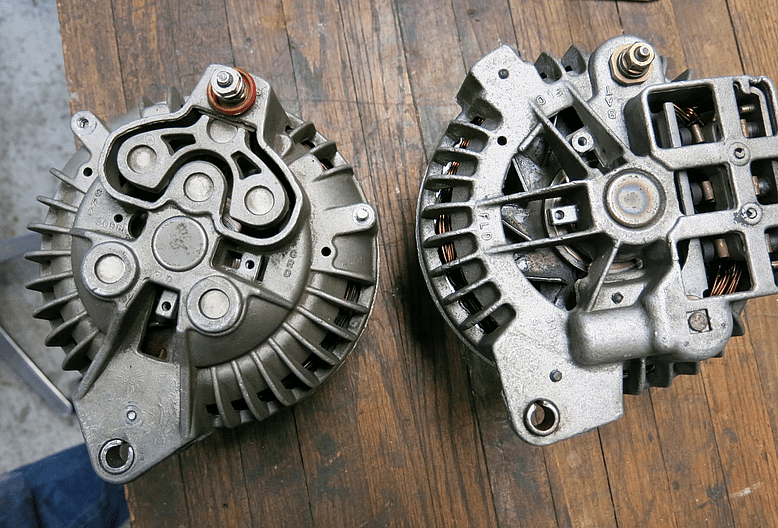

Its good to have extra alternators to compare with.

Notice something different about the rear bearings? Two things actually.

The center of the squareback's bearing is blue from heat, and its flush with the casting. H'mmm. So the rotor shaft must have been lightly bottomed out in the bearing.

Looking at the roundbacks, its seems the bearing wasn't pressed to the right depth. Then when I put the grease retainer on, it must have contacted the inside of the bearing housing.

The fix was pretty easy. Took the alternator halves apart. On the squareback there's room for a 15/16" socket to sit and support the casting while pressing the bearing another 1/16" further. :)

Pulley Alignment.

Pulleys get pressed on until the inside tip contacts the drive end bearing. As shown in the photo, the 2 V removed from the squareback was causing the belt alignment to be a bit off. The solid pulley on the far left weighed in at 1 lb. A factory pulley 7.5 oz, and the solid two groove pulley at 1 lb 7.5 oz after it underwent some weight reduction surgery.

Idealy you're supposed to press the pulley on with a pressure gage so you know when the pulley is contacting the bearing. Well I don't have one. An arbor press would have been nice, but I don't have one of the them either. So I measured the depth with the tail of vernier caliper and then marked the pulley. Then pressed it on.

The pulley has to be installed while the back half of the alternator housing is off.

Installing a new stator took a bit of trial fitting. I didn't want the winding or attachment wires to rub the outer housing or touch the through bolts.

After installing the new stator, decided to take a quick look at the old one to see if it could be fixed.

Removing the insulating tape or shink tubing from the Y connecting joint revealed the break.

Looks like there's enough wire to cut, clean and rejoin....when I have time at the garage...

After reassembling the halves, all looked good,

But the rotor didn't want to turn freely :eek:

Its good to have extra alternators to compare with.

Notice something different about the rear bearings? Two things actually.

The center of the squareback's bearing is blue from heat, and its flush with the casting. H'mmm. So the rotor shaft must have been lightly bottomed out in the bearing.

Looking at the roundbacks, its seems the bearing wasn't pressed to the right depth. Then when I put the grease retainer on, it must have contacted the inside of the bearing housing.

The fix was pretty easy. Took the alternator halves apart. On the squareback there's room for a 15/16" socket to sit and support the casting while pressing the bearing another 1/16" further. :)