Alternator repair, a little show and tell.

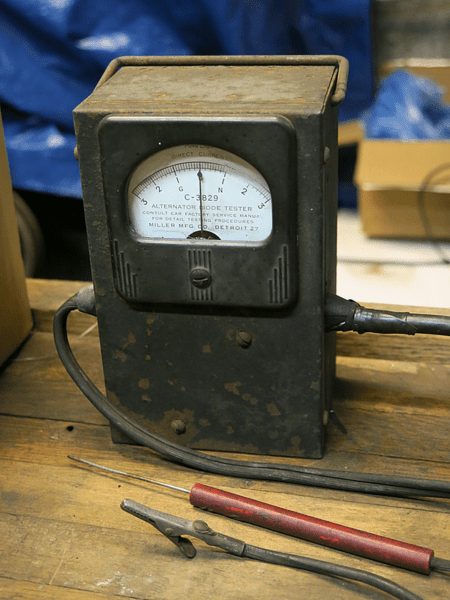

I bought this off e-bay cheap, but was in pretty bad shape. Got it to work but movement isn't smooth. I *think* good enough for a go / no go.

I bought this off e-bay cheap, but was in pretty bad shape. Got it to work but movement isn't smooth. I *think* good enough for a go / no go.

I've got two early roundbacks with open windings in the rotors. I don't want an replacement rotor for the reasons you state. Rewind or nothing as far as I'm concerned. Fixing one of them would only be to have a backup on the shelf or if someome was doing a restoration.

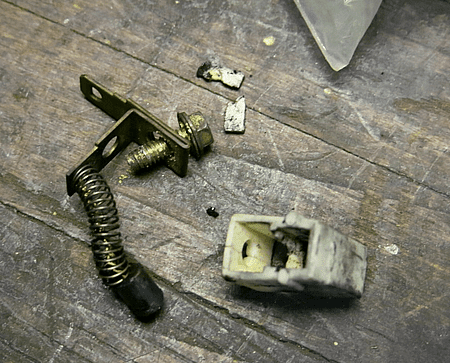

The way I had this alternator set up was a field modification grounding the horizontal brush's terminal. Notice no plastic washer under the head in the second picture, first post.

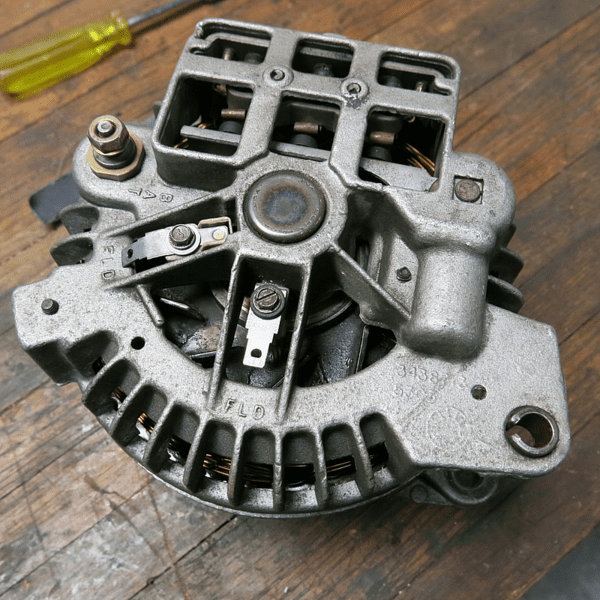

Doing something similar now but a little nicer and want to make sure there's no strain on the field wire so it is on the other terminal.

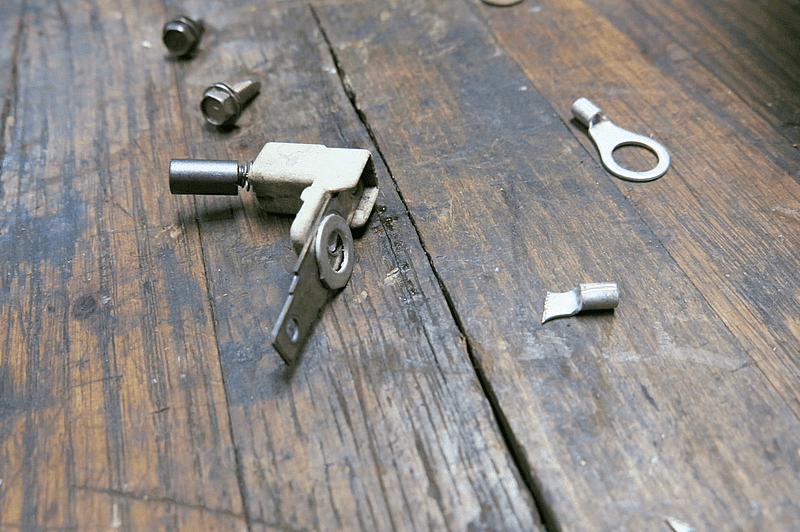

Found a tinned copper ring terminal that fit well and snipped it to make a conductive washer.

Then slightly filed down the raised insulation to be sure the screwhead makes good contact.

I don't know if the early grounded brush will fit. Will try that next, but this will work. Bent the terminal tab down so there's no question about which is the positive and which is the grounded.

Bought most of the parts (not the stator) from these guys.

Chrysler alternator brushesAlternator Parts, Starter Parts, Rebuild Kits, Upgrade Kits

Prices are good and they ship quick. Stuff is mostly Transpo/Wai Wei but I think the brushes are made here.

I had to make up a crib sheet of which brushes and holders go with which alternator...

I did use the ohmeter setting but didn't trust it. The lamps are a good idea for a load test.

Makes sense and probably worse with mix and match rebuilds. This stator came from an old stock that seemed to cross reference correctly. The core and loops seem the same as the old one. The leads are obviously different. The one I took out may or may not be Chrysler original. I think not based on the few pictures of NOS stators I've seen on the web.

I've got two early roundbacks with open windings in the rotors. I don't want an replacement rotor for the reasons you state. Rewind or nothing as far as I'm concerned. Fixing one of them would only be to have a backup on the shelf or if someome was doing a restoration.

Did OK here so far. The one new brush holder I tried needed some deburring so the brush would slip through freely.

The way I had this alternator set up was a field modification grounding the horizontal brush's terminal. Notice no plastic washer under the head in the second picture, first post.

Doing something similar now but a little nicer and want to make sure there's no strain on the field wire so it is on the other terminal.

Found a tinned copper ring terminal that fit well and snipped it to make a conductive washer.

Then slightly filed down the raised insulation to be sure the screwhead makes good contact.

I don't know if the early grounded brush will fit. Will try that next, but this will work. Bent the terminal tab down so there's no question about which is the positive and which is the grounded.

Bought most of the parts (not the stator) from these guys.

Chrysler alternator brushesAlternator Parts, Starter Parts, Rebuild Kits, Upgrade Kits

Prices are good and they ship quick. Stuff is mostly Transpo/Wai Wei but I think the brushes are made here.

I had to make up a crib sheet of which brushes and holders go with which alternator...