I finally got around to fixing a squareback alternator I removed from the Barracuda a year and half ago. It came out because its output was weak. Thought I'd share some of the repairs here. Its not meant to be a complete 'how to.'

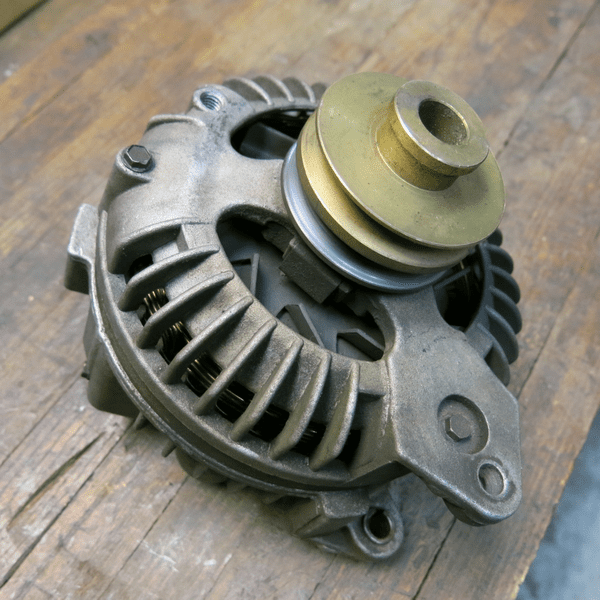

First thing was to remove the pulley. This had nothing to do with the needed repairs. It was about me not liking that pulley. It didn't have great alignment, I didn't need a double V, and so its just extra weight. Yes - I care about weight. Every pound adds up.

Removing pulleys is generally easy if you have a puller.

Unfortunately for me, this pulley had a non-standard nose and none of the pullers I had, or could borrow, fit.

My solution was to grind and file the pulley down until the puller slipped on. Still was a ***** to remove. Too much interference fit. It was maybe scrap before, now I'm never use it again!

Started going through the bench tests in the shop manual. Rotor was good.

Vertical brush was pretty worn. A little surprising for the miles.

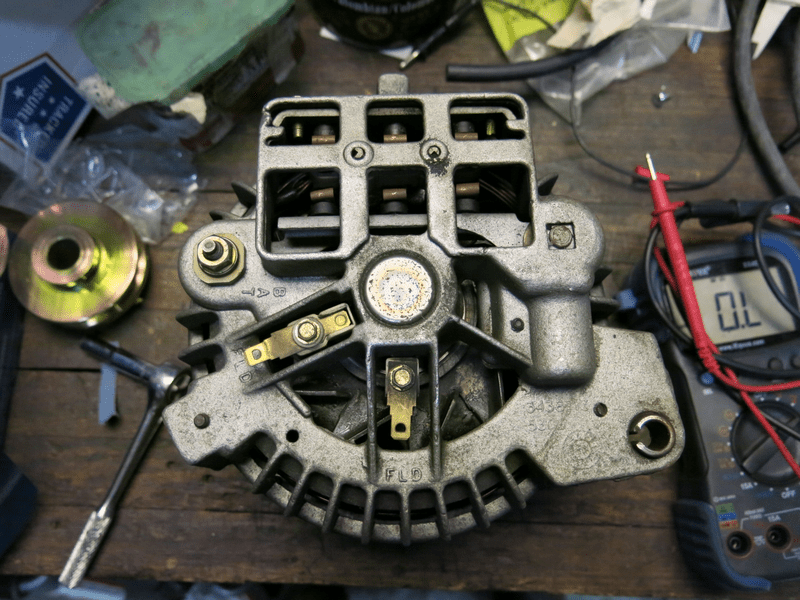

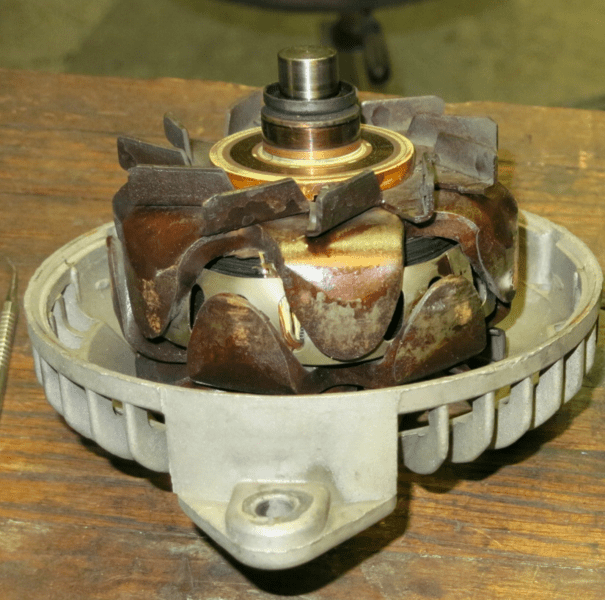

Here's what it looks like inside the back end.

Notice what looks like black grease around the bearing and splattered throughout.

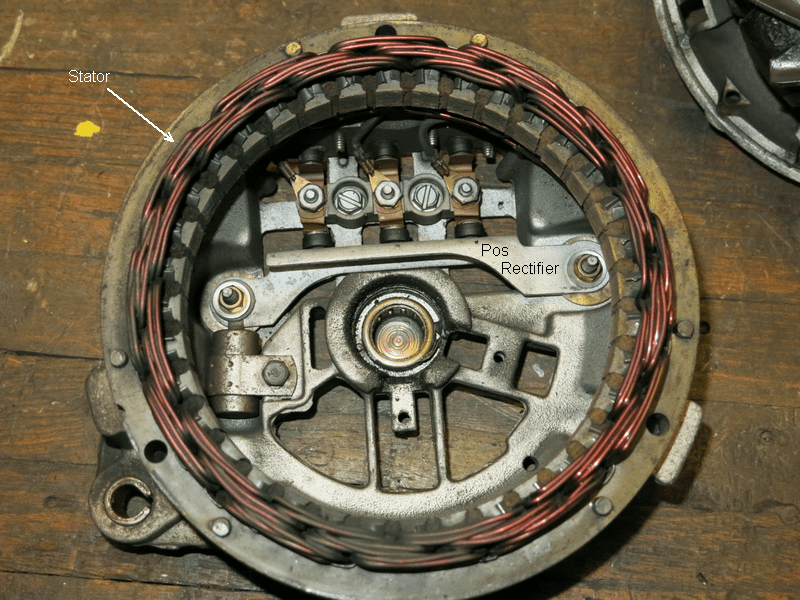

On the squarebacks, the stator windings are bolted to rectifiers. This makes all of the components easy to test and replace if needed.

To my surprise, both rectifiers were good.

Remove the three nuts and take out the stator.

Checking for continuity in the stator windings and found one was open. So that explains why output was low.

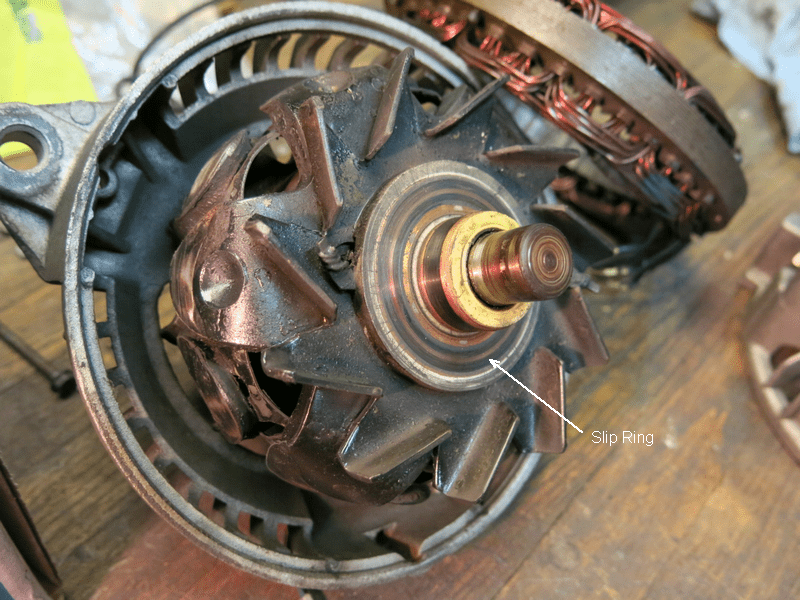

On the front half, the copper slip rings were a little dirty to say the least. I think this is because something is missing. The book shows a grease shield should be in front of the slip rings.

This roundback had the plastic grease shield. Removes pretty easily if you are careful.

to be continued

First thing was to remove the pulley. This had nothing to do with the needed repairs. It was about me not liking that pulley. It didn't have great alignment, I didn't need a double V, and so its just extra weight. Yes - I care about weight. Every pound adds up.

Removing pulleys is generally easy if you have a puller.

Unfortunately for me, this pulley had a non-standard nose and none of the pullers I had, or could borrow, fit.

My solution was to grind and file the pulley down until the puller slipped on. Still was a ***** to remove. Too much interference fit. It was maybe scrap before, now I'm never use it again!

Started going through the bench tests in the shop manual. Rotor was good.

Vertical brush was pretty worn. A little surprising for the miles.

Here's what it looks like inside the back end.

Notice what looks like black grease around the bearing and splattered throughout.

On the squarebacks, the stator windings are bolted to rectifiers. This makes all of the components easy to test and replace if needed.

To my surprise, both rectifiers were good.

Remove the three nuts and take out the stator.

Checking for continuity in the stator windings and found one was open. So that explains why output was low.

On the front half, the copper slip rings were a little dirty to say the least. I think this is because something is missing. The book shows a grease shield should be in front of the slip rings.

This roundback had the plastic grease shield. Removes pretty easily if you are careful.

to be continued