My take on the oiling system crossover tube for the small block

It seems to me that it is the crossover tube itself that gets all the attention

and some people are missing the full necessity of the modification.

People who tube or bush the passenger side of the block accept that the other requirement that goes with This is to also block or cut off the supply to the drivers side. The choice of where to block it is up to the builder, just as long as it gets blocked.

No one questions the effectiveness of this.

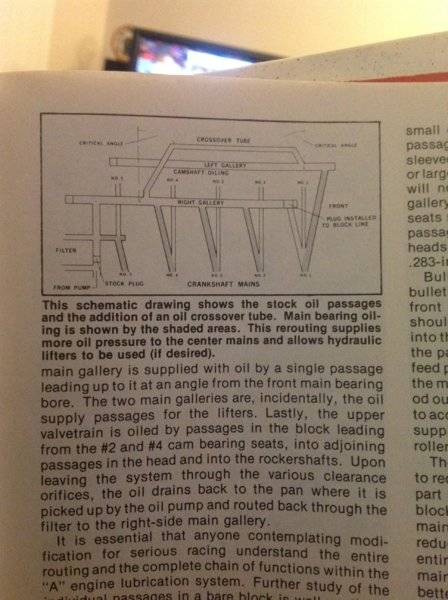

The crossover tube also requires the supply to the drivers side to be blocked on the passenger side as well. Look at the picture I have posted. #1 main is oiled in reverse. All the crossover tube is doing,

Is taking some of the surplus oil volume on the passenger side, routing it over to the drivers side, and oiling #1 main from the drivers side. With the exception of the leakage at the lifters, the crossover combined with the blocking plug at the end of the galley,

accomplishes the same thing but a different way. As Guitar Jones said. The crossover method gives the option of wet lifter bores while reinforcing the oil to the main and rod bearings. It's just an optional way.

The plug at the end of the galley cuts off the supply to drivers side to stop the oil feed to the drivers side lifters being taken from number one main. Even front oiling requires the same thing. The plug kills the velocity.

Earlier today I was rereading the Sanborn oiling thread and he mentioned that he ran a crossover line to use pushrod oiling. In my case I am using roller lifters with no needle bearings. They are bushed roller lifters with edm oil feed passages directly to the axles. They need some oil.

The Chevy has a separate oil galley for each bank of lifters and a 3rd to feed the cam bearings and main/rods. No one bearing is asked to feed more than one other bearing. It does not need a crossover for that reason.

On the Chrysler number 1 main is asked to feed 9 other leaks.

These 9 leaks combined with a high volume/pressure pump causes the velocity.

Why else would all three of these modifications require blocking the end of the galley with a plug. As usual just mho.

The oil timing is a different issue.

Jada forgot to post one other picture. Earlier in this thread replicar made a comment to Jadas about the crossover tube just oiling #1 main from both ends.

It seems to me that it is the crossover tube itself that gets all the attention

and some people are missing the full necessity of the modification.

People who tube or bush the passenger side of the block accept that the other requirement that goes with This is to also block or cut off the supply to the drivers side. The choice of where to block it is up to the builder, just as long as it gets blocked.

No one questions the effectiveness of this.

The crossover tube also requires the supply to the drivers side to be blocked on the passenger side as well. Look at the picture I have posted. #1 main is oiled in reverse. All the crossover tube is doing,

Is taking some of the surplus oil volume on the passenger side, routing it over to the drivers side, and oiling #1 main from the drivers side. With the exception of the leakage at the lifters, the crossover combined with the blocking plug at the end of the galley,

accomplishes the same thing but a different way. As Guitar Jones said. The crossover method gives the option of wet lifter bores while reinforcing the oil to the main and rod bearings. It's just an optional way.

The plug at the end of the galley cuts off the supply to drivers side to stop the oil feed to the drivers side lifters being taken from number one main. Even front oiling requires the same thing. The plug kills the velocity.

Earlier today I was rereading the Sanborn oiling thread and he mentioned that he ran a crossover line to use pushrod oiling. In my case I am using roller lifters with no needle bearings. They are bushed roller lifters with edm oil feed passages directly to the axles. They need some oil.

The Chevy has a separate oil galley for each bank of lifters and a 3rd to feed the cam bearings and main/rods. No one bearing is asked to feed more than one other bearing. It does not need a crossover for that reason.

On the Chrysler number 1 main is asked to feed 9 other leaks.

These 9 leaks combined with a high volume/pressure pump causes the velocity.

Why else would all three of these modifications require blocking the end of the galley with a plug. As usual just mho.

The oil timing is a different issue.