360 Tune Up

If the mechanical advance is too quick, then it will ping at part throttle loads when used with a vacuum advance.

34* by 2400 rpm, plus vacuum advance of 17* is very different than 34* at 3400 rpm with another 17* added by vacuum.

Stick a golf tee the vac hose. Then check the timing at the slowest rpm and every 250 or 500 rpm until 3000 or it stops advancing.

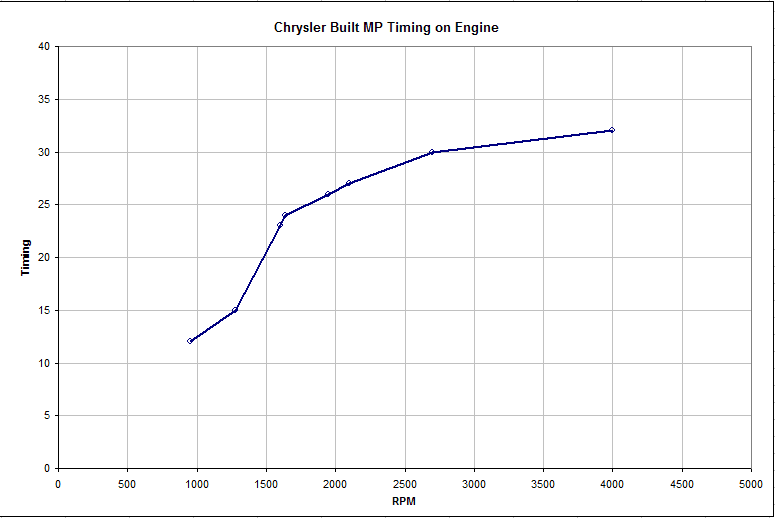

Result will look something like this when graphed.

Go to section 3 here for Mopar Performance's baseline for timing.

The Mopar Performance baseline timing recommendation assumes a timing curve like the one posted above.

That particular distributor idled around 12* BTC when set at 31* at 3000 rpm. On a stock 340 or 360 that would be OK. On a hot rodded engine, 16 to 20* might be needed depending on the cam and compression. That's one reason why I wasn't able to get a timing below 900 rpm. The engine I had it on needs around 17* initial.

I can't say if that's realistic, but its a great goal However in my experience as long as you are tuning and testing mpg will be low. So don't sweat it too much right now.

I agree with MopaR&D. A cold engine, a warm engine, and a fully heat soaked engine are three different things. Make adjustments to carb with warmed and fully heat soaked for tuning. Choke for cold. Choke setting are the hardest thing to nail on a hot rod.

Indicated how? At higher speed cruise, too lean will show as engine reving and dying.

OK. Sounds like timing is about on the edge, at least for some conditions.

You may be still on winter fuel. June 1 all stations in the US will be back to summer fuel.

These numbers look OK but need to get the rpm and vacuum to really know.

If the mechanical advance is too quick, then it will ping at part throttle loads when used with a vacuum advance.

34* by 2400 rpm, plus vacuum advance of 17* is very different than 34* at 3400 rpm with another 17* added by vacuum.

Stick a golf tee the vac hose. Then check the timing at the slowest rpm and every 250 or 500 rpm until 3000 or it stops advancing.

Result will look something like this when graphed.

Go to section 3 here for Mopar Performance's baseline for timing.

The Mopar Performance baseline timing recommendation assumes a timing curve like the one posted above.

That particular distributor idled around 12* BTC when set at 31* at 3000 rpm. On a stock 340 or 360 that would be OK. On a hot rodded engine, 16 to 20* might be needed depending on the cam and compression. That's one reason why I wasn't able to get a timing below 900 rpm. The engine I had it on needs around 17* initial.