SBM Distributor overhaul DIY?

So will delaying the advance.

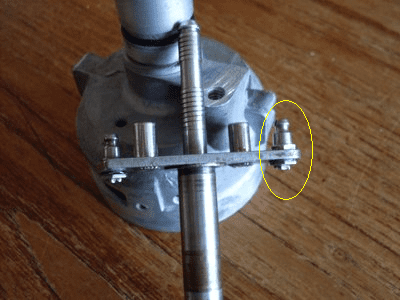

Turning the primary spring's perch will increase the tension (assuming its not maxed out already)

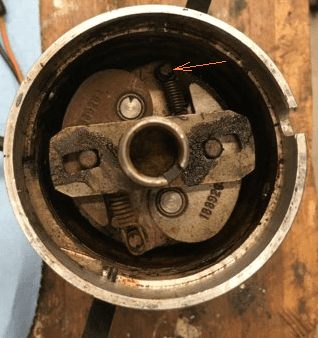

It's on an eccentric.

More tension delays the rpm the weights move out.

If it started advancing at 500 rpm, and you were trying to idle at 600 rpm then the timing will vary with small changes in rpm.

* The curve may not have actually topped out at 3000 rpm. The springs may have just slowed it to 1* per 500 rpm or less.

* Timing at idle was 15* but initial timing was less. Direct Connection did that on their race distributors to guarentee easy starting but it makes idle erratic as its very rpm dependent.

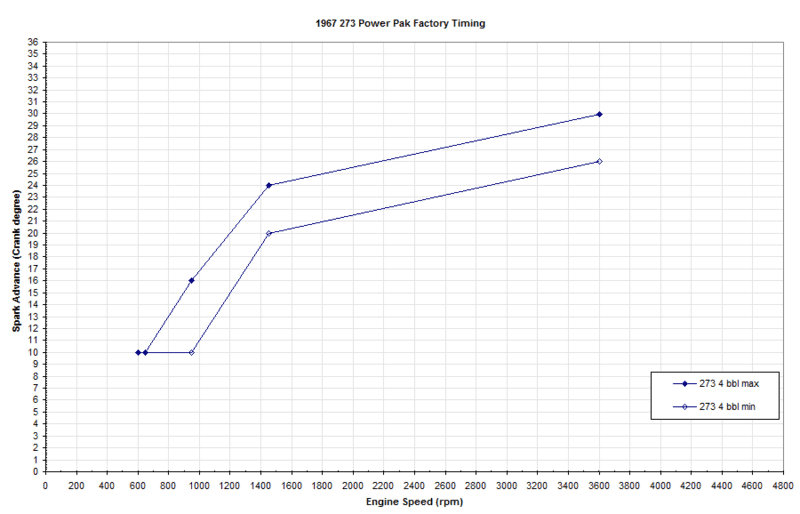

To give an idea of how each adjustment works, lets look at a pre-CAP timing curve.

For a perfomance small block we can turn to the 1967 Plymouth 273 4bbl specs.

Bet more initial will help.

So will delaying the advance.

Turning the primary spring's perch will increase the tension (assuming its not maxed out already)

It's on an eccentric.

More tension delays the rpm the weights move out.

If it started advancing at 500 rpm, and you were trying to idle at 600 rpm then the timing will vary with small changes in rpm.

yes

Two possibilities, and it could be either or both.

* The curve may not have actually topped out at 3000 rpm. The springs may have just slowed it to 1* per 500 rpm or less.

* Timing at idle was 15* but initial timing was less. Direct Connection did that on their race distributors to guarentee easy starting but it makes idle erratic as its very rpm dependent.

To give an idea of how each adjustment works, lets look at a pre-CAP timing curve.

For a perfomance small block we can turn to the 1967 Plymouth 273 4bbl specs.