1972 Duster Build with my Daughter

Ok story so far. I have gone through 2 compressors and 2 expansion valves on the Duster. The compressors where my fault and the valves where to experiment because the AC worked like crap from the day put the first can of freon in it. I have been talking with a couple of the guys on the B-Body site who have worked in the AC business for a long time and I think we have the problem. I have my Coronet that will cause icicles to form on my nose sitting next to the Duster which is lucky to put out 55 degree air.

Through these two I have learned what sub cooling and super heating is and how to measure it. What we found was there was 30 degrees of superheating (evaporator) when there should be about 10. The subcooling was about 10 degrees (condenser) which was about right.

There was no reason why it should not be working. Finally we gave up and I modified my Murray (O'Rilley) expansion valve to close down the orifice by a significant amount. The modification was a hack and now that I pulled the 4 Seasons valve apart I understand how it is suppose to work. When I pulled both valves of the box I french kissed both of them to blow through and see how much restriction where was. I was sort of surprised to find almost no restriction but did not understand AC enough at the time to put 2 and 2 together. Back to the experiment. The AC worked 100% better. The pressures where correct and the outlet of the evaporator was frosty cold and sweating just like I would expect! That is when the thought went into the expansion valve.

I thought about how the valve should work. If the temperature probe is too warm (like room temperature in my hand) the valve should be choking off the liquid freon like crazy to try to get a huge pressure drop converting the freon back to a gas which requires energy by absorbing heat (read... effective cooling, an AC does not make cool it absorbs heat from the air). When the probe starts to freeze it should move the orifice so there is less of a pressure drop (opens up the valve) so it can flood more liquid freon and not use as much energy and not pull as much heat out of the evaporator. That said at room temp the orifice should be closed off trying to get a huge pressure drop. Well the 2 new and original valve in my had at room temperature I could blow though the valve with almost no noticeable restriction at all..... The modified one I could detect a noticeable restriction trying to blow through it. We where on to something.

One thought I had was maybe these cheap aftermarket valves were just poor in tolerance stack up in manufacturing and the orifice was been held open too far when the probe was hot.

Here is my experiment with the 4 Seasons....

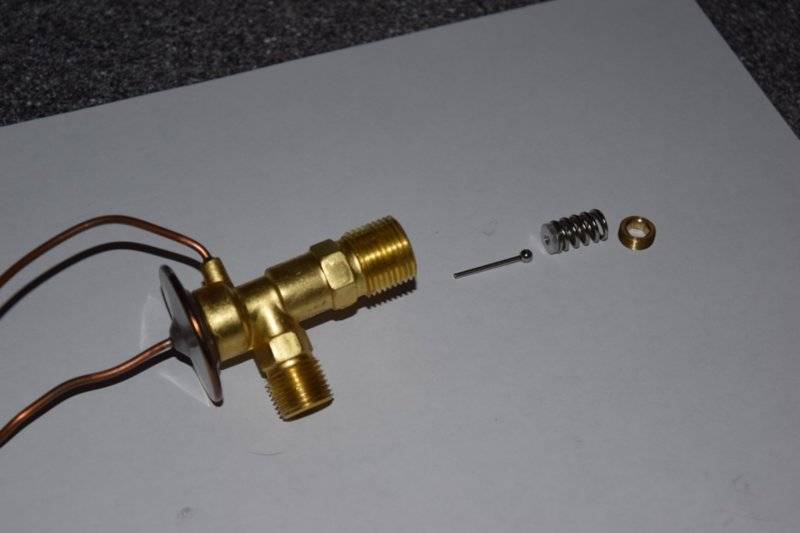

The orifice is SUPER simple and it is adjustable but you have to open the system to try a new adjustment.....

An allen wrench to remove the nut and a spring and pressure plate pops out. Thin needle nose pliers to grab the orifice ball and the orifice and pin are removed. That is all there is. The temperature probe and equalization pressure tube are connected to the valves rear diaphragm. As the R134a in the probe heats and cools it move the diaphragm pushing on the end of the pin and orifice ball to open/close it.

Notice the seating surface for the ball is on the same side as the pin! The pin must be able to go back into the valve enough such that the back edge of the ball contacts the brass seat

Here is the orifice pin installed

I found if I pressed down on the ball with the allen wrench that the air flow restriction went way up.... Like I said is the problem a tolerance stack up problem with manufacturing?

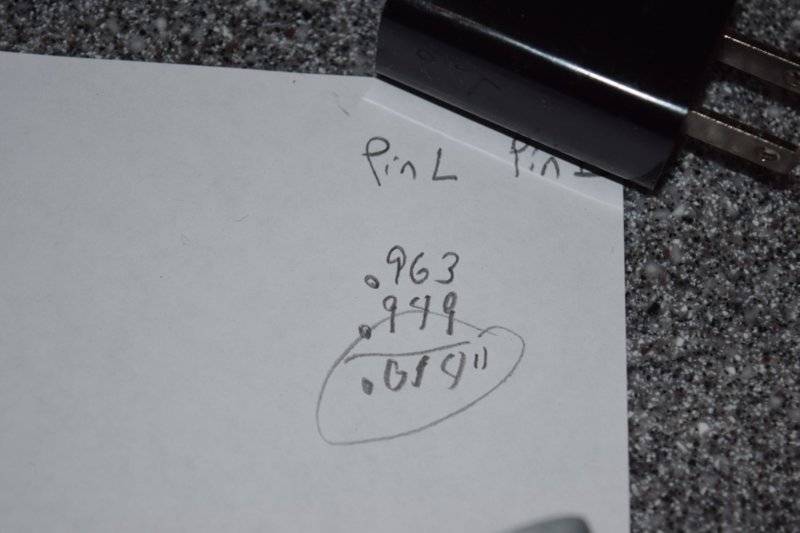

I measured the orifice and it was 0.963" long.

I then got out my dremel tool and ground it down to 0.949" long or removed 0.014" of length.

Now when I put the orifice in and put a bit of pressure on it I could barely blow through it! Now we can make some Freon gas!

Here is the pressure plate with a cup machined into fit onto the orifice ball. The spring and nut adjusts how much pressure is pushing against the diaphram to fine tune the sub cooling temperature.

Ok story so far. I have gone through 2 compressors and 2 expansion valves on the Duster. The compressors where my fault and the valves where to experiment because the AC worked like crap from the day put the first can of freon in it. I have been talking with a couple of the guys on the B-Body site who have worked in the AC business for a long time and I think we have the problem. I have my Coronet that will cause icicles to form on my nose sitting next to the Duster which is lucky to put out 55 degree air.

Through these two I have learned what sub cooling and super heating is and how to measure it. What we found was there was 30 degrees of superheating (evaporator) when there should be about 10. The subcooling was about 10 degrees (condenser) which was about right.

There was no reason why it should not be working. Finally we gave up and I modified my Murray (O'Rilley) expansion valve to close down the orifice by a significant amount. The modification was a hack and now that I pulled the 4 Seasons valve apart I understand how it is suppose to work. When I pulled both valves of the box I french kissed both of them to blow through and see how much restriction where was. I was sort of surprised to find almost no restriction but did not understand AC enough at the time to put 2 and 2 together. Back to the experiment. The AC worked 100% better. The pressures where correct and the outlet of the evaporator was frosty cold and sweating just like I would expect! That is when the thought went into the expansion valve.

I thought about how the valve should work. If the temperature probe is too warm (like room temperature in my hand) the valve should be choking off the liquid freon like crazy to try to get a huge pressure drop converting the freon back to a gas which requires energy by absorbing heat (read... effective cooling, an AC does not make cool it absorbs heat from the air). When the probe starts to freeze it should move the orifice so there is less of a pressure drop (opens up the valve) so it can flood more liquid freon and not use as much energy and not pull as much heat out of the evaporator. That said at room temp the orifice should be closed off trying to get a huge pressure drop. Well the 2 new and original valve in my had at room temperature I could blow though the valve with almost no noticeable restriction at all..... The modified one I could detect a noticeable restriction trying to blow through it. We where on to something.

One thought I had was maybe these cheap aftermarket valves were just poor in tolerance stack up in manufacturing and the orifice was been held open too far when the probe was hot.

Here is my experiment with the 4 Seasons....

The orifice is SUPER simple and it is adjustable but you have to open the system to try a new adjustment.....

An allen wrench to remove the nut and a spring and pressure plate pops out. Thin needle nose pliers to grab the orifice ball and the orifice and pin are removed. That is all there is. The temperature probe and equalization pressure tube are connected to the valves rear diaphragm. As the R134a in the probe heats and cools it move the diaphragm pushing on the end of the pin and orifice ball to open/close it.

Notice the seating surface for the ball is on the same side as the pin! The pin must be able to go back into the valve enough such that the back edge of the ball contacts the brass seat

Here is the orifice pin installed

I found if I pressed down on the ball with the allen wrench that the air flow restriction went way up.... Like I said is the problem a tolerance stack up problem with manufacturing?

I measured the orifice and it was 0.963" long.

I then got out my dremel tool and ground it down to 0.949" long or removed 0.014" of length.

Now when I put the orifice in and put a bit of pressure on it I could barely blow through it! Now we can make some Freon gas!

Here is the pressure plate with a cup machined into fit onto the orifice ball. The spring and nut adjusts how much pressure is pushing against the diaphram to fine tune the sub cooling temperature.