Some ideas and questions about the FORD 8.8 axle:

https://www.mscdirect.com/product/details/33366667?fromRR=Y

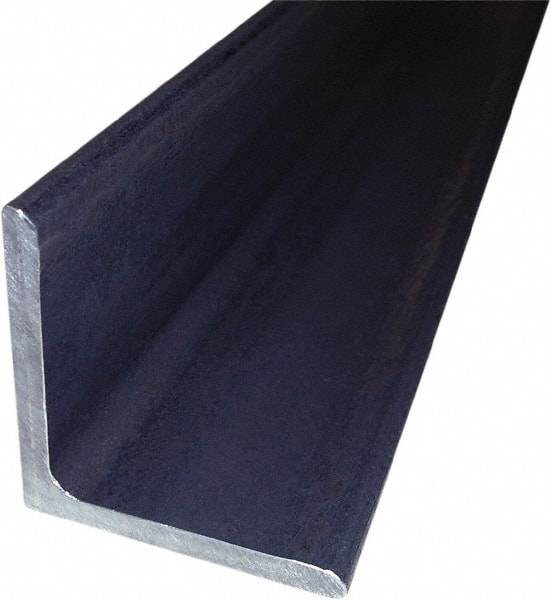

If you grind/clean the outside of the axle tube nice and smooth, then cut out the excess out (as straight a cut as possible), then lay the tubes in a piece of angle iron (large piece, like 4" X 4" angle iron)....the angle iron will keep everything dead straight if you clamp the pieces into the angle iron. Then you tack weld in three places on the exposed side, grind the tack welds smooth and rotate the tubes in the angle iron with clamps and tack weld the other side. By tack welding (only) you will not "pull" the tubes to one side like it would if you fully welded it and by keeping the tubes clamped into the angle iron it will keep the tubes straight. Be sure and bevel the cut edges to get a full weld and make sure to mark the "clock" position of the brake (flange) position before cutting so that you can locate the axle flange properly before welding. Once it's tack welded you can weld 100 percent without any distortion/warpage in the tubes. To be safe you can tack weld in numerous spots before fully welding the tubes. Just be sure to grind smooth and rotate so that your not continuously welding on one side only.

https://www.mscdirect.com/product/details/33366667?fromRR=Y