Guides that are on the loose side won’t cause any real problems other than premature seat wear.

Tight guides on the other hand can be catastrophic.

If you can’t get anywhere with a sensible machine shop, then you’ll pretty much have to do it yourself.

Pull them apart, keep everything in order.

Remove any assy lube from the valves & guides.

Give them the wiggle test.

With everything clean and dry, there should def be discernible play.

But not sloppy loose.

Lap in the valves, look for a uniform shade of gray all around the valve and seat.

Don’t excessively lap the valves.

15 seconds or so is plenty.

If it takes more lapping than that, there’s a problem.

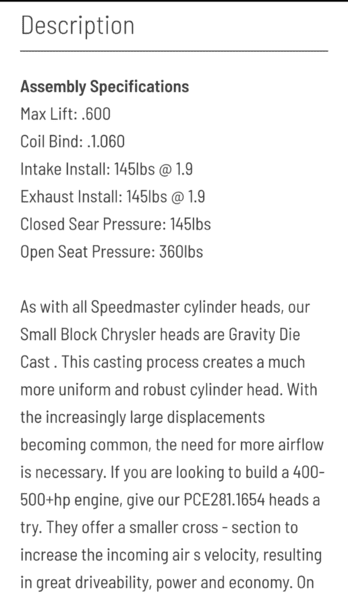

Measure the installed height of the springs, and bring them, along with a retainer to a shop with a high quality tester and have them tested(with the retainer) at the installed height you measured, and the lift of your cam(installed height minus cam lift).

Straight edge on the decks.

I like them within .003 of flat for a 4 cylinder head.

Finish needs to be quite smooth for MLS gaskets.

If it’s all good, and the spring loads are a good match for your cam...... put them back together.