Has anyone successfully used the USCartool A500 Crossmember?

Since I actually have an original piece in the garage, and a piece of 1/4" x 1 1/4" mild steel, I went to see what I could bend:

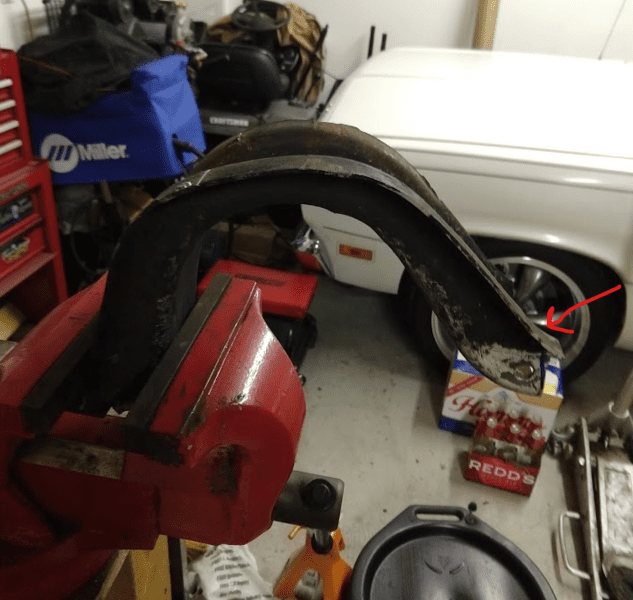

By applying force at the arrow with my bare hands (I'm 6'/185 and work an office job, so I'm no body builder), I could put a radiused 90 degree bend in this steel bar no sweat. My bench isn't even bolted to the wall or floor so the force is pretty low. I could also bend it almost all the way back before the table moved. The moment arm here is 6" or so, so not huge.

I pushed as hard as I possibly could at the arrow on the factory piece and I couldn't get any permanent deformation, it only flexes a tiny bit. I even moved my table. No way is that going to be stronger than the factory piece. My shadetree garage test is also showing that direction. The floors on these cars are pretty weak so it's not doing much.

You might be able to "get away with it" being dependent on the lower piece (which is bolt in so it may move somewhat just do to that), given that the lower piece is no doubt pretty stout. I don't think any of us would build a frame rail, roll cage or subframe connectors out of a flat bar with a bend in it. They're always tubing. When this is welded to the floor it's approximating a box tube.

You'll see that in my crossmember they use some plate welded at 90's to get a similar shape, it doesn't deflect either. Remember I also had my floor cut out to do my swap and the whole thing becomes a lot more floppy. I also have subframe connectors. Not much holds the car together between the left and right rails, why make it any weaker? I know it's difficult for people to redo their whole floor due to that, so do what you want. I just don't recommend it.

Since I actually have an original piece in the garage, and a piece of 1/4" x 1 1/4" mild steel, I went to see what I could bend:

By applying force at the arrow with my bare hands (I'm 6'/185 and work an office job, so I'm no body builder), I could put a radiused 90 degree bend in this steel bar no sweat. My bench isn't even bolted to the wall or floor so the force is pretty low. I could also bend it almost all the way back before the table moved. The moment arm here is 6" or so, so not huge.

I pushed as hard as I possibly could at the arrow on the factory piece and I couldn't get any permanent deformation, it only flexes a tiny bit. I even moved my table. No way is that going to be stronger than the factory piece. My shadetree garage test is also showing that direction. The floors on these cars are pretty weak so it's not doing much.

You might be able to "get away with it" being dependent on the lower piece (which is bolt in so it may move somewhat just do to that), given that the lower piece is no doubt pretty stout. I don't think any of us would build a frame rail, roll cage or subframe connectors out of a flat bar with a bend in it. They're always tubing. When this is welded to the floor it's approximating a box tube.

You'll see that in my crossmember they use some plate welded at 90's to get a similar shape, it doesn't deflect either. Remember I also had my floor cut out to do my swap and the whole thing becomes a lot more floppy. I also have subframe connectors. Not much holds the car together between the left and right rails, why make it any weaker? I know it's difficult for people to redo their whole floor due to that, so do what you want. I just don't recommend it.