Speedmaster Small block porting tips and results Part 1

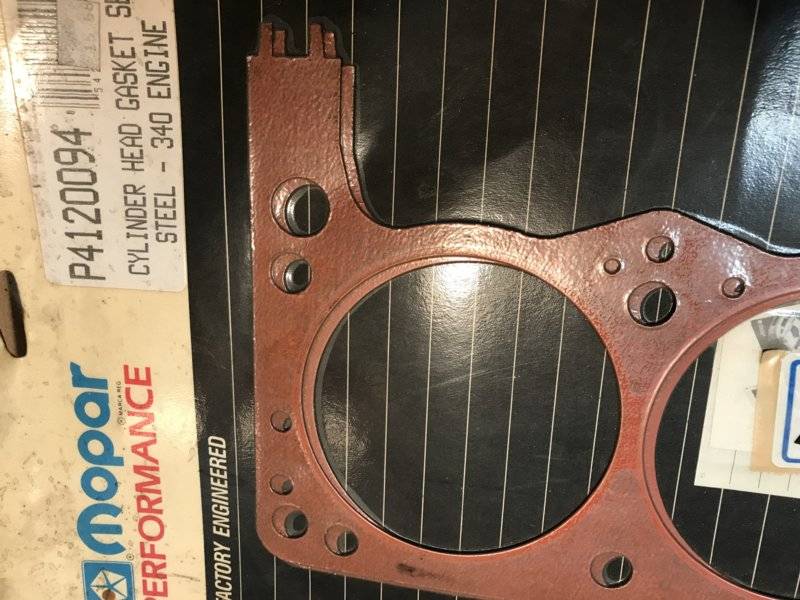

I grabbed these a while ago, to use on my 410 (.040” over bore) to get a little more cr, assuming they would work even though they are for bigger 340 bores. Curious about the DG logo, and what the compressed thickness would be. I’ve read they are .028” thick (mine still sealed) that’s it. Can you fill me in? Thanks