Performance timing

OP has a regular MP one (with vac advance, no tach drive) or a copy. If its a copy then who knows what's in it. Only way to be sure will be make some timing - rpm measurements,

Initial or base timing: Timing at an rpm with no advance added.

Normally on a stock engine timing at idle is the baseline. Idle is usually 500 - 650 rpm (pre-smog), or 600 - 700 rpm smog era.

Hot rodded and race engines requires some trial and error tuning to get the idle speeds down anywhere close to 700 rpm.

When you are measuring timing at idle it is critical to note the rpm. Timing at 800 or 900 rpm will likely be base timing plus some advance unless the spring tension is increased. Don't worry about it. Just write down the rpm.

Mechanical Advance: Degrees added by the distributor's weights moving outward with rpm. Usually just called advance.

Total Timing: Initial timing plus the maximum mechanical advance. With hot rods and race engines, sometimes the idle timing is very unstable, especially early in the tuning process. For that reason, a high rpm timing measurement is a better reference. For example, mopar performance instructions suggest measuring at 2800 rpm.

Purpose:

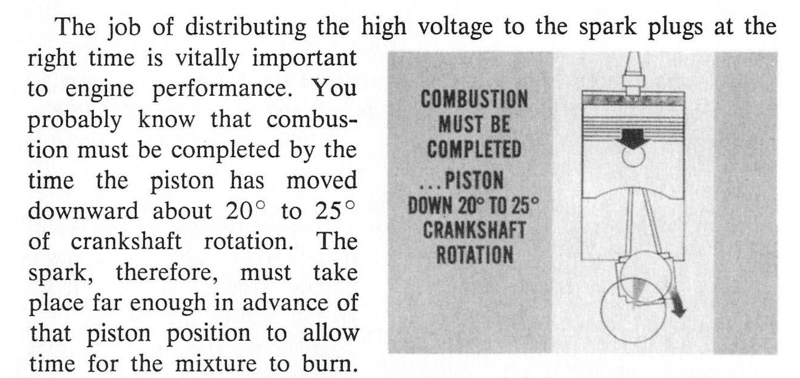

Mechanical or Centrifical Advance

Compensates for the reduced amount of time (miliseconds) available for the burn as rpm increases. Its not directly proportional because engine efficiency decreases burn time as rpms climb. A 'low performance' 318 usually has good lower rpm efficiency, but does not gain as much efficiency with increasing rpm. A 'high performance engine' is usually the opossite.

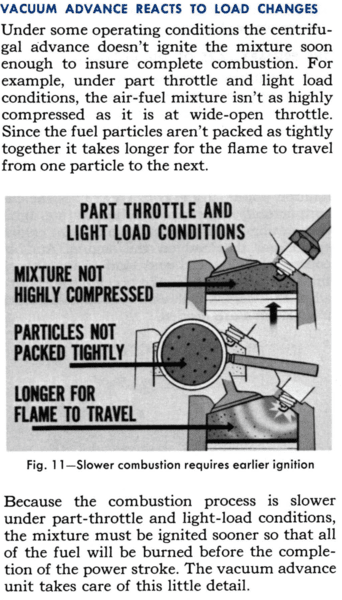

Vacuum Advance:

I've posted a chart from the Direct Connection Bulletin as well as graphs of what I measured. Tach drive distributors are super fast in. Work great for the drag strip, and easy starting for high comp engine with a manual transmission.

Yup. That's for the one for tach drive distributors.

OP has a regular MP one (with vac advance, no tach drive) or a copy. If its a copy then who knows what's in it. Only way to be sure will be make some timing - rpm measurements,

Maybe. But probably the curve will be further from ideal since the engine combustion characteristics are now rather different than a stock 2 bbl 318 would have had.

Initial or base timing: Timing at an rpm with no advance added.

Normally on a stock engine timing at idle is the baseline. Idle is usually 500 - 650 rpm (pre-smog), or 600 - 700 rpm smog era.

Hot rodded and race engines requires some trial and error tuning to get the idle speeds down anywhere close to 700 rpm.

When you are measuring timing at idle it is critical to note the rpm. Timing at 800 or 900 rpm will likely be base timing plus some advance unless the spring tension is increased. Don't worry about it. Just write down the rpm.

Mechanical Advance: Degrees added by the distributor's weights moving outward with rpm. Usually just called advance.

Total Timing: Initial timing plus the maximum mechanical advance. With hot rods and race engines, sometimes the idle timing is very unstable, especially early in the tuning process. For that reason, a high rpm timing measurement is a better reference. For example, mopar performance instructions suggest measuring at 2800 rpm.

Purpose:

Mechanical or Centrifical Advance

Compensates for the reduced amount of time (miliseconds) available for the burn as rpm increases. Its not directly proportional because engine efficiency decreases burn time as rpms climb. A 'low performance' 318 usually has good lower rpm efficiency, but does not gain as much efficiency with increasing rpm. A 'high performance engine' is usually the opossite.

Vacuum Advance: