What Are You Doing To/With Your Car Today?

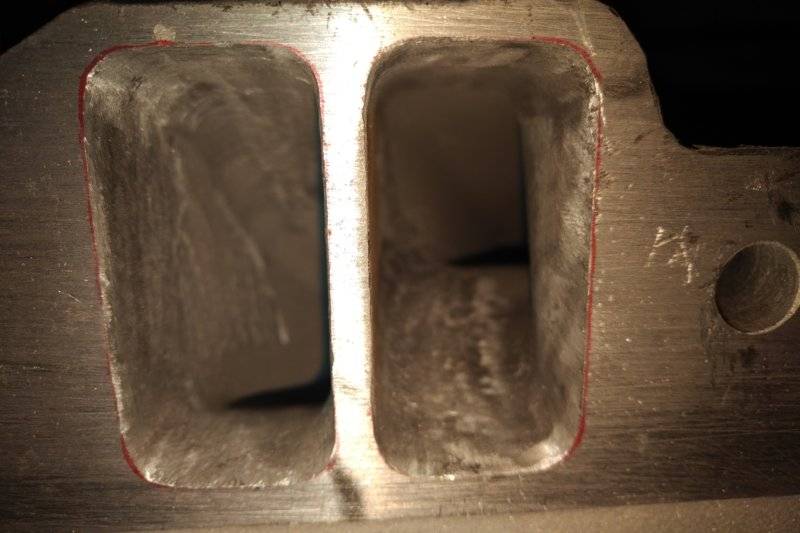

Done with the RPM Airgap for the 360 build. It is kinda hard to see in the pictures, but the runners are pretty smooth now as far as I could reach. I cleaned it up with 80 grit tootsie rolls, then a wire brush. There were some ugly casting boogers that I got rid of in the plenum, as well as in the water passage up front.

Next up for this is the gasket matching the 308 heads. I'll pull them out of the shed and bring them in to work on after work next week. At least that grinding will be a LOT easier, I'll just use a stone. I hate how aluminum likes to gum up stones and tootsie rolls.

I also have a smaller set of 273/318 intake manifold gaskets floating around here somewhere to match my Offy 2x4 manifold and the 302 heads, which I'll probably do some time this spring. I may not even use those heads for a while, and they'll probably just go on a teener for my son when he starts driving in nine years. I suspect that I'm gonna use that 2x4 on the 318 to 392 WEDGE project. If I do that, I suspect that I may want to add some meat to the outside of the runners so I can enlarge the insides of the runners. JB Weld or TIG?

Done with the RPM Airgap for the 360 build. It is kinda hard to see in the pictures, but the runners are pretty smooth now as far as I could reach. I cleaned it up with 80 grit tootsie rolls, then a wire brush. There were some ugly casting boogers that I got rid of in the plenum, as well as in the water passage up front.

Next up for this is the gasket matching the 308 heads. I'll pull them out of the shed and bring them in to work on after work next week. At least that grinding will be a LOT easier, I'll just use a stone. I hate how aluminum likes to gum up stones and tootsie rolls.

I also have a smaller set of 273/318 intake manifold gaskets floating around here somewhere to match my Offy 2x4 manifold and the 302 heads, which I'll probably do some time this spring. I may not even use those heads for a while, and they'll probably just go on a teener for my son when he starts driving in nine years. I suspect that I'm gonna use that 2x4 on the 318 to 392 WEDGE project. If I do that, I suspect that I may want to add some meat to the outside of the runners so I can enlarge the insides of the runners. JB Weld or TIG?