1969 Barracuda Fastback

Midland and Ross brake booster installation:

The last days I devoted some time to the brake booster and master cylinder. Since Mopar is new to me, I always go through the service manual and 69 parts list before putting hands on something. I found out, that I am missing two parts on the brake booster:

Gasket to the firewall (which was somehow logical - bare metal to paint is rare) and the spacer with a filter element to master cylinder.

The gasket was an easy task, cut it out of a Felpro rubber/fiber gasket material.

The spacer was a bit more of a challenge, but I found a nice NOS piece on eBay.

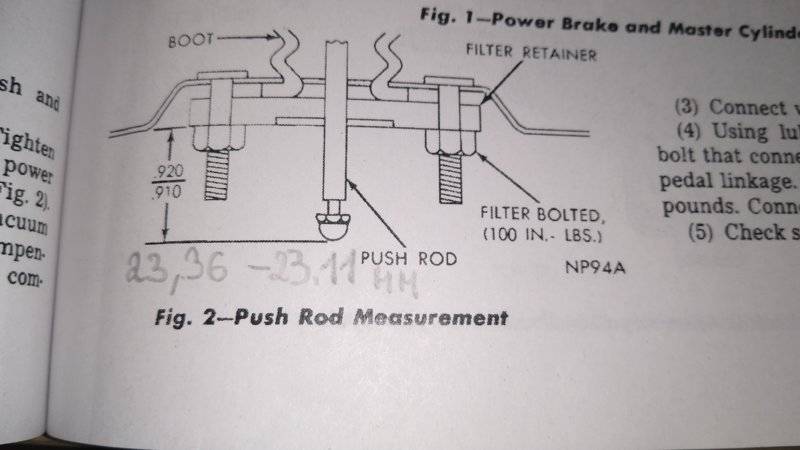

Ok, since I got all the parts I could start doing some measurements for the brake booster pushrod setting. The brake system will stand or fall with the setting of the pushrod - so I measured everything a couple of times.

- The good thing on the Midland and Ross brake booster is, that you can remove the pushrod which makes measuring and setting easier.

When I inserted the caliber in the Master Cylinder, I got a reading which perfectly matched the specs in the manual. Also, BoosterDewey preset the pushrod exact to factory specs - BTW, very nice move.

Well, but that would have been too easy. I did not trust this appearance, especially since the master cylinder is a reproduction piece. After putting some chalk on the pushrod nut and inserting it in the master cylinder, my concerns got confirmed. The radius machined in the master cylinder did not perfectly match the radius of the nut on the pushrod. Just inserting the gauge on the caliber would have given me always a wrong reading - but the nut did not touch the very bottom of the cylinder. That would have caused a too-long set pushrod.

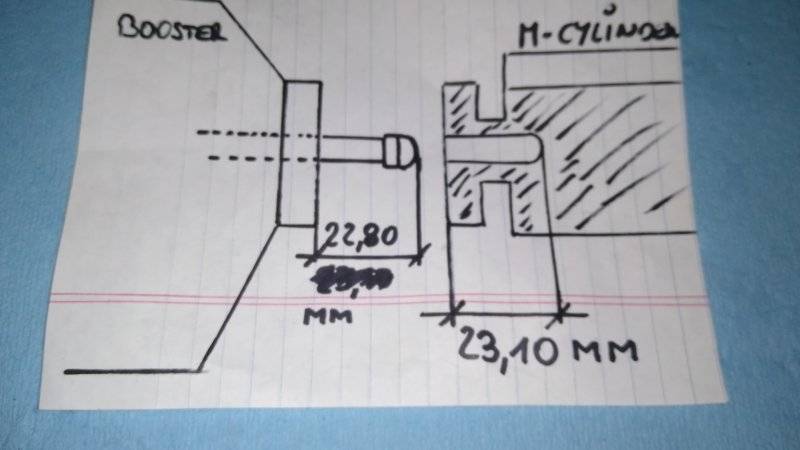

In order to determine the length needed, I inserted the pushrod into the master cylinder and measured it this way - the first step completed.

- The bad thing about the Midland and Ross Brake booster is, after installing the spacer you do not really have a flat surface to take accurate measurements. Like on my previous project, I used one of my little handy, homemade multitools (use it also for pulling the steering wheel and many other jobs).

It helped me to keep the pushrod centered and simulated even distributed tension to the spacer. Master cylinder bolts were tightened to specs (9ft pounds).

I grew up with the metric system, so measurements taken for myself are in mm, but might be a reference for somebody using the same components.

I am sure there are better approaches, but many ways lead to Rome - that's the one I took.

Here some pictures:

Midland and Ross brake booster installation:

The last days I devoted some time to the brake booster and master cylinder. Since Mopar is new to me, I always go through the service manual and 69 parts list before putting hands on something. I found out, that I am missing two parts on the brake booster:

Gasket to the firewall (which was somehow logical - bare metal to paint is rare) and the spacer with a filter element to master cylinder.

The gasket was an easy task, cut it out of a Felpro rubber/fiber gasket material.

The spacer was a bit more of a challenge, but I found a nice NOS piece on eBay.

Ok, since I got all the parts I could start doing some measurements for the brake booster pushrod setting. The brake system will stand or fall with the setting of the pushrod - so I measured everything a couple of times.

- The good thing on the Midland and Ross brake booster is, that you can remove the pushrod which makes measuring and setting easier.

When I inserted the caliber in the Master Cylinder, I got a reading which perfectly matched the specs in the manual. Also, BoosterDewey preset the pushrod exact to factory specs - BTW, very nice move.

Well, but that would have been too easy. I did not trust this appearance, especially since the master cylinder is a reproduction piece. After putting some chalk on the pushrod nut and inserting it in the master cylinder, my concerns got confirmed. The radius machined in the master cylinder did not perfectly match the radius of the nut on the pushrod. Just inserting the gauge on the caliber would have given me always a wrong reading - but the nut did not touch the very bottom of the cylinder. That would have caused a too-long set pushrod.

In order to determine the length needed, I inserted the pushrod into the master cylinder and measured it this way - the first step completed.

- The bad thing about the Midland and Ross Brake booster is, after installing the spacer you do not really have a flat surface to take accurate measurements. Like on my previous project, I used one of my little handy, homemade multitools (use it also for pulling the steering wheel and many other jobs).

It helped me to keep the pushrod centered and simulated even distributed tension to the spacer. Master cylinder bolts were tightened to specs (9ft pounds).

I grew up with the metric system, so measurements taken for myself are in mm, but might be a reference for somebody using the same components.

I am sure there are better approaches, but many ways lead to Rome - that's the one I took.

Here some pictures: